Fraunhofer Institute for Chemical Technology (ICT)

Fraunhofer-Gesellschaft

Joseph-von-Fraunhofer-Strasse 7

Pfinztal (Berghausen), 76327 DE

49 721 4640 0

info@ict.fraunhofer.de

ict.fhg.de

About Fraunhofer Institute for Chemical Technology (ICT)

The core competence of the Polymer Engineering Department includes research on engineering plastics and fiber-based composites. As a link between research and industry, the institute's staff work with partners to develop innovative system solutions for future lightweight products.

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Fraunhofer Institute for Chemical Technology (ICT) Supplies the Following Products

- Aerospace, aircraft interior

- Automotive, body panels & substructures

- Carbon/carbon composites

- Consulting, environmental

- Consulting, materials

- Consulting, process development

- Infrastructure, composite

- Materials analysis

- Other composite structures

- Product design

- Testing, environmental

- Testing, materials

- Testing, product

- Testing, structural

Editorial, News, and Products

-

Innovation Award finalists revealed for JEC World 2024

Returning to the international composites trade show are the Innovation Awards, representing up to 33 finalists in 11 categories that highlight composites innovation excellence and fruitful collaborations.

-

JEC Forum DACH reveals Startup Booster, AVK Innovation award winners

Awards highlight dynamic composite innovations in industry.

-

Sumitomo Bakelite Europe conference highlights importance of composites for electric mobility

Composites for Future Mobility Conference attracts more than 50 delegates from OEMs, Tier suppliers and research institutions which are finding numerous composite opportunities in electric motors, UAM.

-

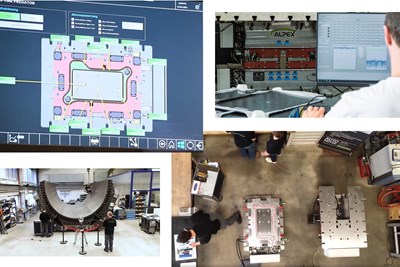

Digitizing tools for composites production

Alpex Technologies focuses on industrialization, process and part intelligence and biocomposites in its next generation of tooling systems.

-

Sensors for Composites Processing: CW Trending Episode 8

Why use sensors in composites manufacturing? What sensor types are available and how can they be applied? Learn about all of this and more in a discussion with CW senior editor Ginger Gardiner and editor-in-chief Jeff Sloan in this episode of CW Trending, sponsored by RVmagnetics.

-

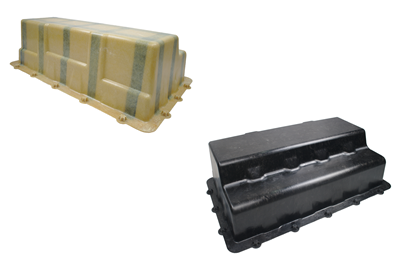

SMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

-

Plant tour: Bucci Composites, Faenza, Italy

A stalwart in Italy’s “Motor Valley” opens its doors for a discussion and exploration of the company’s history in composites manufacturing for high-performance cars and other applications.

-

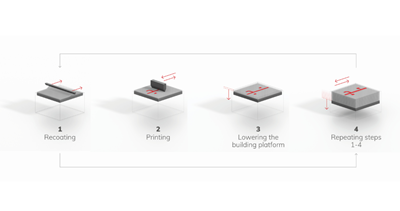

GE, Fraunhofer IGCV, Voxeljet to develop the world’s largest 3D printer for offshore wind applications

The partnership will streamline the production of key components of GE’s Haliade-X offshore wind turbine with the advance casting cell (ACC) sand binder jetting 3D printer.

-

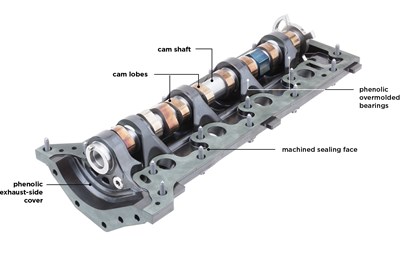

Glass fiber and phenolic prove their mettle in camshaft module

Replacing aluminum, a fiberglass/phenolic module reduces mass and NVH in a prototype structure and speeds assembly line installation.

-

AVK announces winners of 2020 Innovation Awards

Several sustainable composite innovations were recognized and awarded in the Innovative Products/Applications, Innovative Processes and Research and Science categories.

-

Demonstrating recyclable, bio-based autocomposites

The ECOXY research consortium recently developed a demonstrator automotive part constructed from recyclable flax fiber and a specialized bio-based epoxy.

-

Composites industry events focus on recycled carbon fiber, filament winding

CETMA and Suez present a workshop on recycled carbon fiber, MF Tech announces global filament winding convention, and SAMPE 2020 abstracts are due Nov. 15.

-

Dieffenbacher, Arburg partner to offer combined injection/transfer molding process

The companies demonstrated their combined capabilities with a recent project to develop a modular injection/transfer molding cell to produce hybrid parts.

-

Automotive composites draw international crowd to Detroit

19th SPE ACCE features broad technology overview of evolving automotive composites industry.

-

Composites-focused engineering, simulation services company launches in Germany

Simutence GmbH, a company started by Karlsruhe Institute of Technology graduates, offers custom simulation methods to composites manufacturers across end markets.

-

Bio4self bio-based autocomposite wins JEC Innovation Award

The Bio4self consortium has developed a bio-based and easily recyclable composite material. It is suitable for mechanically demanding components in the automotive industry.

-

JEC World 2019 preview: Fraunhofer IPT

Fraunhofer Institutes for Production Technology (IPT, Aachen, Germany, 5/D17) is emphasizing work it did with Fraunhofer Institute for Laser Technology (ILT, Aachen) on the EU research project ComMUnion, in collaboration with 14 partners from industry, to develop industrial processes and solutions for hybrid lightweight design by combining metal and polymer-matrix composites for automotive and aerospace applications.

-

Reducing heat in EV motors via fiber-reinforced thermoset housing and stator

German researchers demonstrate fiber-reinforced phenolic motor housing and alumina-filled epoxy overmolded stator with integrated cooling circuits for reduced weight, increased power density and efficiency.

-

Continuous tapes, D-LFT meet up in new compression molding process

Design research for an automotive load floor module drove development of a new compression molding process for direct-long-fiber thermoplastic (D-LFT) composites.

-

Hybrid thermoplastics give load floor impact strength

Project leads to development of new compression process for selective application of D-LFT on UD tape laminates.

-

Lightweighting summit: Targeting composites auto powertrain opportunities

The Lightweight Composites Solution Conference, held May 17 in Gent, Belgium, focused on materials and designs for reducing automotive powertrain weight.

-

Fraunhofer presents melt-spinning technology for carbon fiber precursor manufacture

New ComCarbon PAN-based precursor technology will reportedly make it possible to produce carbon fibers at low cost for the mass market.

-

Fraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

-

Plant Tour: Fraunhofer ICT, Pfinztal, Germany

This wide-ranging research center works with government and industry to develop the best of polymer composite processing, across a range of technologies.

-

A look inside Fraunhofer ICT

Fraunhofer-Gesellschaft (Munich, Germany) is the largest applied research organization in Europe, with more than 67 institutes and research units located throughout Germany staffed by 24,500 people, mostly scientists and engineers. CW recently got a chance to tour one, Fraunhofer ICT in Pfintzal, Germany.

-

SMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

-

Wait, wait, there’s more: JEC 2017

There’s never enough time to see everything at the JEC World event, and this year the problem was even worse. Here’s more information on new products and companies, from Paris…

-

Another opportunity to meet, and learn, in Paris

At the JEC World 2017, improvements in materials and processes were present at nearly every stand, with the emphasis on automotive-capable production speeds.

-

Recyclable epoxy proven in HP-RTM

Recyclamine hardener performs well in global processing trials and cradle-to-cradle recycling demo.

-

Cooperating on new-generation ground transport

CompositesWorld's editor-in-chief Jeff Sloan shares his observations about the mixture of excitement and anxiety about the future of composite in the auto industry on display at the recent Thermoplastics Composites Conference for Automotive (TCCA), held in the Detroit suburb of Novi, MI, US.

-

Breathing-mold process yields sandwich composite from LFT

In-cavity foaming and controlled mold-opening technique creates core and faceskins from a single injection molded material, reducing part mass and boosting performance.

-

Materials & Processes: Fiber formats for composites

Fibers used to reinforce composites are supplied directly by fiber manufacturers and indirectly by converters in a number of different forms, which vary depending on the application. Here's a guide to what's available.

-

Lower cost, less waste: Inline prepreg production

New technologies move direct (fabricator-based) prepregging closer to reality.

-

Alternative precursor R&D: Lignin in the lightweighting limelight

This abundant, renewable resource shows promise as an alternative to PAN for low-cost, functional carbon fibers.

-

Turnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

-

VOC reduction strategies for LFRT composites

Additives supplier seeks novel methods to limit VOC emissions from long-fiber-reinforced thermoplastics.

-

SPE’S ACCE 2015 Preview

Automotive composites remain a hot topic in the Motor City.

-

Thermoplastic composites technology: A view from Europe

For this Dutch consortium, bringing the manufacturability of thermoplastic materials to maturity is the goal in concert with OEMs, materials and equipment supplier members.

-

Carbon fiber as a replacement for glass fiber in D-LFT auto parts

Research progresses toward attainment of 80-90% of continuous carbon fiber tensile modulus in lighter parts molded from direct long fiber thermoplastic compounds.

-

The rise of HP-RTM

Decades of development have propelled it to prominence but its future demands industrial solutions for handling cost, complexity and process control.

-

Fraunhofer ICT develops lightweight cylinder casing

Car manufacturers may be able to achieve weight savings with cylinder blocks that feature parts made of fiber-reinforced plastics.

-

SPE ACCE report

Automotive composites still on the horizon — are they getting closer?

-

SPE ACCE 2014 report

Automotive composites still on the horizon — are they getting closer?

-

Infusible thermoplastics via in-situ polymerization

A low-viscosity monomer that can be polymerized in the mold enables infusion of continuous glass fiber with polyamide 6.

-

Printed circuit boards: A mobile market

Glass fiber/epoxy prepregs have dominated the mammoth PCB market for decades. Will that continue in a time of great change?

-

Structural preform technologies emerge from the shadows

Not yet in full production, with one exception, all are aimed at accelerating composite part manufacture at fast automotive rates.

-

Hybrid thermoplastic molding: Toughening automotive composites

Tailored D-LFT with continuous and discontinuous glass offers best combination of strength, moldability.

-

SPE ACCE 2012 Review

Bursting at the seams, the 12th annual Society of Plastic Engineers Automotive Composites Conference and Exhibition tops its previous bests.

-

Formulation flexibility: Direct-SMC

Consortium applies inline-compounding technology to reinvent sheet molding compound.

-

SPE ACCE 2011: Growing again

The Society of Plastics Engineers’ 11th conference on automotive composites fields a top slate of speakers and attracts its largest crowd.

-

On the road again

CT's editor-in-chief Jeff Sloan offers a quick review of doings at this year's SPE Automotive Composites Conference & Exhibition, recently presented in Troy, Mich.

-

2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

-

SPE's ACCE 2010 preview

Charting a composites course through the auto industry’s “perfect storm.”

-

Interior innovation: The value proposition

OEMs and Tier suppliers ask materials and molding processes to go “green” and do more for less.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

-

UBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

-

SPE's ACCE 2009 Show Preview

The Society’s 2009 Automotive Composites Conference & Exhibition charts an industry at a crossroads.

-

JEC COMPOSITES 2009 Product Showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.