Durable composite pallet comes to market

Selective reinforcements paired with commodity materials, plus long-term partnerships, make this pallet concept a winner.

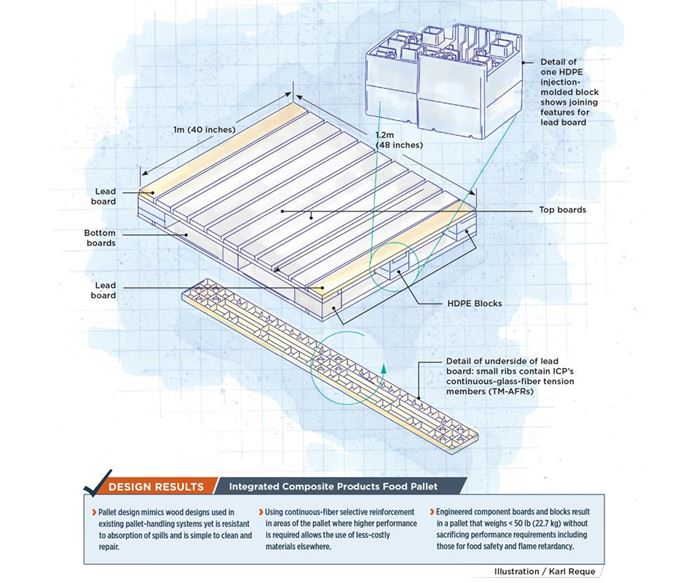

Design results:

- Pallet design mimics wood designs used in existing pallet-handling systems yet is resistant to absorption of spills and is simple to clean and repair.

- Using continuous-fiber selective reinforcement in areas of the pallet where higher performance is required allows the use of less-costly materials elsewhere.

- Engineered component boards and blocks result in a pallet that weighs <50 lb (<22.7 kg) without sacrificing performance requirements, including those for food safety and flame retardancy.

In the ubiquitous and growing transportation packaging market, valued by some reports at more than US$15 billion, 2 billion pallets are made and used each year in the US alone. The vast majority of pallets are made of wood. Those used to transport food products typically follow the Grocery Manufacturers Assn. (GMA, Washington, DC, US) design. Although wood is strong and renewable, it presents problems for pallet owners and lessors of “pooled” pallets. It absorbs water and spilled product, becoming unsanitary, difficult to clean and attractive to insects and fungi. Critical to the food industry, wood pallets are easily damaged, hard to repair and often fail in such a way that wood splinters and foreign material can enter the food being processed or transported. As a result, the pallet market is facing regulatory pressure and even bans on wood pallets in some countries and US states.

“Many people have tried to commercialize heavier-duty composite pallets. All have struggled and many have failed,” says Derek Mazula, CEO of Integrated Composite Products Inc. (ICP, Winona, MN, US). “We thought, how can we selectively reinforce a composite pallet, and do it in a way that meets all of the industry’s requirements, but allow the customer to save money and supply chain partners to make money?” ICP’s answer, advanced fiber reinforcements (AFRs), combines a unique technology, robust design and a vertically integrated group of partners, including customers, who are ready to eliminate wood and corrugated cardboard from their plants.

Overcoming cost/performance tradeoffs

Mazula and ICP’s chief science officer and long-time industry innovator Ron Hawley deliberately avoided previous composite pallet design missteps. They knew their product would need to pass myriad performance tests under ISO 8611-1:2011, Pallets for Materials Handling. One test, for example, is deflection under load when edge-racked (when all the load is located on one edge). Beyond high strength and stiffness, the pallet would have to offer good durability and impact resistance (often at odds with flexural strength), yet weigh less than 50 lb (22.7 kg) — a US Occupational Safety and Health Admin. requirement — clean up well, repair easily and meet National Fire Protection Assn. (NFPA) fire retardance requirements.

“This was essentially an impossible set of requirements for the composite pallets that had gone before,” Mazula notes, “but we had ICP’s advanced technologies, a savvy design approach and confidence gained from three years of R&D.”

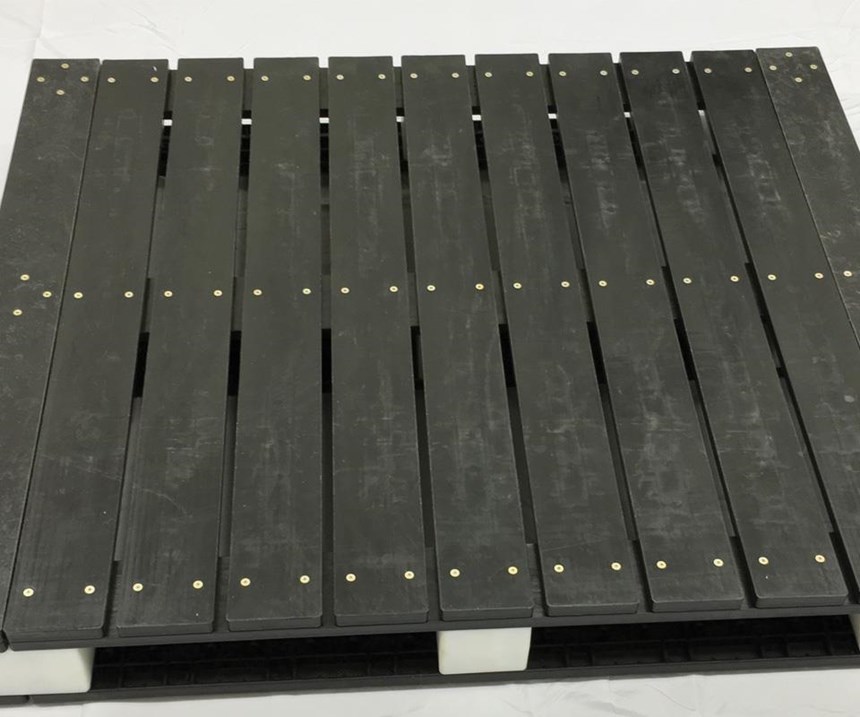

ICP’s pallet would look like a GMA-standard wood pallet, with the same 1m by 1.2m (40- by 48-inch) dimensions, to integrate seamlessly into existing handling systems. But the pallet would be made from compression-molded polypropylene (PP) composite “boards” — sized almost identically to a wood pallet’s boards, at 1m to 1.2m long, 100 mm wide and 19 mm thick (40 or 48 inches by 4 inches by 0.75-inch). These would be mechanically fastened to eight injection-molded, high-density polyethylene (HDPE) blocks at the corners and along the pallet’s centerline (see the detail in the drawing, above).

The keys to weight and cost control would be ICP’s (pat. pend.) AFRs, manufactured by ICP and partners that include Saint-Gobain ADFORS (Grand Island, NY, US). The AFRs would be placed only in pallet regions that demand higher performance. is would allow ICP to use materials, including long fiber-reinforced thermoplastic (LFT), provided by partners that include Mafic (Toronto, ON, Canada), elsewhere to optimize the pallet.

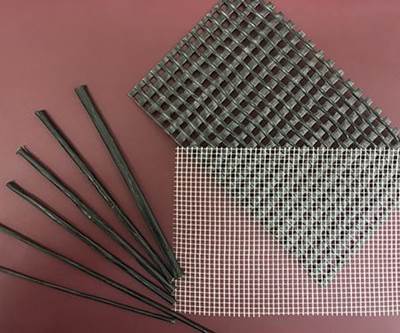

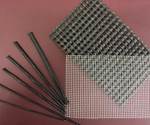

AFRs are of three types (for background on AFR development and their types, see CW's previous coverage of this subject, titled "Selective reinforcements boost 'commodity' composite properties"):

- Tension members (TM-AFRs), pultruded rods with continuous axial glass fibers in a thermoplastic resin matrix, in a range of thicknesses/filament counts, placed at the bottom or end of ribs;

- Structural members (SM-AFRs), flexible meshes of continuous glass fibers with a resin coating in a range of weights, embedded in pallet element walls;

- Impact members (IM-AFRs) also contain a woven mesh and are embedded in pallet element walls but use a modifed resin formulation to impart flexibility for impact absorption.

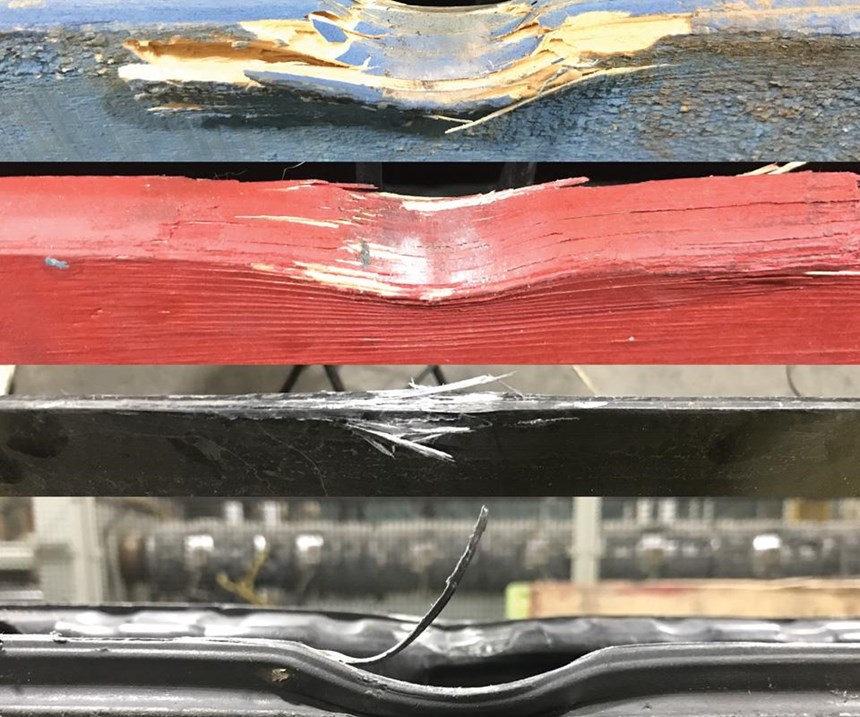

The low-cost PP resin, either a long-fiber thermoplastic (LFT) or reinforced with short glass fiber, would flow around and encapsulate the specially designed and formulated AFRs. “Our goal was to custom-design the pallet elements for the required performance, with full knowledge of their likely failure modes, and make them virtually indestructible,” says Mazula, “by strategic placement of AFRs that would make up only 5-10% of the pallet.”

Optimizing via DoE and FEA

Although ICP knew exactly where it should place its AFRs to achieve the maximum effectiveness, the question of how the ICP team would optimize each AFR type and each base resin/glass matrix for the design proved to be far more involved. Says Hawley, “The sheer number of design factors/combinations with AFRs — types, sizes, formulations, etc. — base resin matrices — percentage glass, melt flows, formulations, etc. — and the interdependent impact of part designs — rib depths, rib heights, wall thickness, etc. — for each board and block as well as the entire pallet system was staggering!”

Hawley designed a single mold that could produce the variety of boards needed to prove out ICP’s conceptual design: “With just a single board mold and wood blocks, we could make a wide variety of prototype pallet components that could readily be tested at the ICP Center. We relied on our team’s experience, coupled with rigorous designs of experiments (DOE) on prototype parts to narrow the solution set.”

Pallet “lead” boards (those in contact with lift-truck forks) were designed for harsh use, including impact forces of 100 ft-lb or more from fork-lift truck masts. Pallet blocks would experience even harsher impacts from the “business end” of the fork tines, because they are routinely speared or “pinwheeled.” Lead boards, flat on top, were molded with several, small lengthwise ribs on the underside, each rib containing an AFR-TM rod (with the appropriate number of filaments) at its bottom (see drawing). Boards also incorporated SM-AFR mesh and PP resin reinforced with LFT (higher glass percentages required for performance) to provide structural support. The selectively placed IM-AFR mesh, which is formulated with a resin coating incompatible with the PP molding resin, doesn’t co-melt completely with the molding resin, but retains some flexibility to better absorb big impacts. Top center pallet boards also have unique and proprietary features factored into their design. The underside of select boards offer molded-in bosses to receive conventional fasteners that attach the boards to the HDPE blocks.

ICP and design partner Inform Product Development (Sun Prairie, WI, US) developed a proprietary advanced materials model for finite element analysis (FEA), using leading programs, including HyperWorks’ platform, a division of Altair (Troy, MI, US), to assess the behavior of the molded pallet under static and dynamic loads as well as typical uses, with AFRs and without, and with varying glass loading percentages in the resin. Adds Mazula, “ICP’s proprietary model evaluates true ‘composite interactions’ of each ICP AFR and the base resin/glass matrix.” Ultimately, Hawley and Mazula found good correlation, ±5%, between the model’s predicted performance and the experimental results.

Control of shrinkage was critical to maintaining board dimensional stability. “Neat polypropylene shrinks 20 mils per part inch, but with the glass loadings we’re using, at 40-50%, and with the molded ribs and bosses, shrinkage is reduced to 2 mils per inch,” Mazula explains, pointing out, “We will need minimal to no secondary operations to control part flatness and to facilitate efficient assembly.” ICP also designed beveled bottom boards to allow for easy access by material handling equipment, such as “walkies.” To address the tendency for pallets to become trapezoidal in shape when dropped or impacted repeatedly, ICP has factored in design elements to resist shape change, which also aid assembly.

The use of polybrominated diphenyl ethers (PBDEs) as a fire retardant is a concern for many retailers and shippers. ICP partnered with Arbor Plastic Technologies (Sterling Heights, MI, US), to provide a non-halogenated, non-brominated food-contact-safe fire retardant that is compliant with US Food and Drug Admin. (FDA, Washington, DC, US) directives. It has passed all required flame tests, and can be added at low loading levels with minimal performance impact.

Vertically integrated roll out

The key AFR technologies and ICP’s method of pallet design are proven and ready for market introduction. The pallet has passed all ISO 8611 tests with flying colors, and Underwriters Laboratories (UL) and FM approval certications are underway. The company says it is collaborating with several molding partners, all followers of best practices used in the automotive industry, who have dedicated production capacity to meet committed orders from a variety of large end-customers, beginning this year.

Mazula says one of the US’s largest protein suppliers and packers, along with a variety of produce suppliers, are prepared to adopt the pallet in multiple plants or even system wide. ICP’s partners, including Smart Logistics LLC (Minneapolis, MN, US), have pioneered a model for assembling, cleaning and servicing of pallets that further reduces the projected cost per use (or turn, the term used in the leased pool market).

Concludes Mazula, “Our ... AFR technologies are the prerequisite allowing for lighter, less costly and higher performing solutions. Concurrent with the pallet’s 2017 introduction, we will continue design work on ICP’s Universal Assembled Platform (UAP), which will allow for integration of pallets, bins and a variety of smaller totes later in 2017 and into 2018."

Related Content

3D-woven composites find success in aerospace, space

CAMX 2024: Bally Ribbon Mills experts are displaying the company’s various joints, thermal protection system (TPS) technologies and other 3D woven composites for mission-critical applications.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

Selective reinforcements boost “commodity” composite properties

Strategically placed advanced reinforcements reduce weight, cost while dramatically increasing mechanical performance and dimensional stability.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)