Illustrated by Susan Kraus

All road vehicles have batteries, and all vehicle batteries require protection in case of a crash, vehicle fire or other emergency. In the case of a gasoline-powered vehicle, the relatively small battery — whose role is mostly to provide electricity for starting the engine and powering accessories such as lights and sound systems — is often protected by a standard metal battery enclosure.

In battery electric vehicles (BEV), the batteries are larger, heavier and more vital to the propulsion of the vehicle. Thus, a BEV’s battery enclosure needs to offer even more protection. Moreover, compared to gasoline-powered vehicles, BEVs are often designed differently, as well, with batteries located farther back on the vehicle, which changes overall weight distribution. All of this means that typical metal boxes designed for a BEV can become prohibitively heavy. However, lighter composite battery enclosures offer the opportunity to reduce that weight. In the instance of large, mass-transit BEVs such as battery-electric city buses, the case for lighter, non-metallic battery enclosures is even more compelling.

The goal was to build batteries for a fleet of electric city buses for a U.S. bus manufacturing company.

In the recent case of a U.S. bus manufacturer, the need for a lightweight battery enclosure that could be designed to fit within a tight space envelope led to new opportunities for TRB Lightweight Structures (Huntingdon, U.K.), a company well known for design and manufacture of composite components for the rail, automotive, aerospace and industrial markets. Recently, the company has transitioned its materials knowledge and automation experience into the electric vehicle market, with a battery enclosure scheduled to begin serial production at the company’s new U.S. manufacturing facility in Richmond, Ky., in early 2021.

According to Andrew Dugmore, president of TRB Group, the company has supplied composite honeycomb panels for racing and low-volume sports cars for decades. While supplying parts for the NIO (Shanghai, China) EP9 electric sportscar, which was designed for the Formula E racing circuit, TRB was approached about development of a composite battery enclosure for the vehicle — a new application at the time for the company. It was a short-run project, Dugmore says, with only 24 sets of top and bottom battery covers produced by hand. In the process, the team learned how to build a battery cover to very tight tolerances, meet high impact requirements and mechanical properties, and provide the weight savings desired.

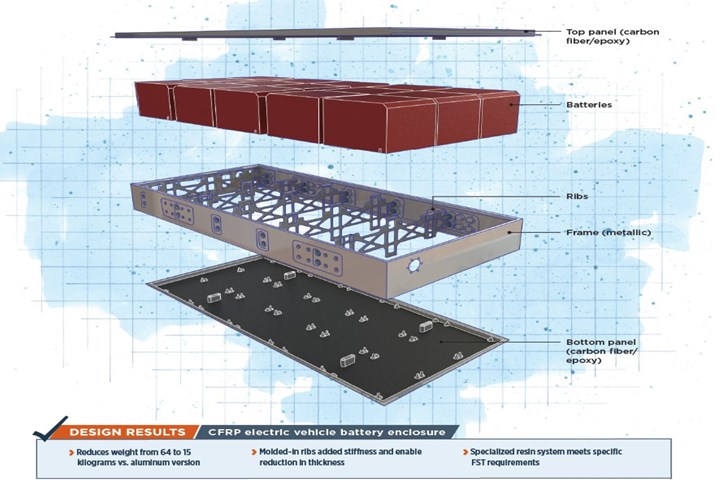

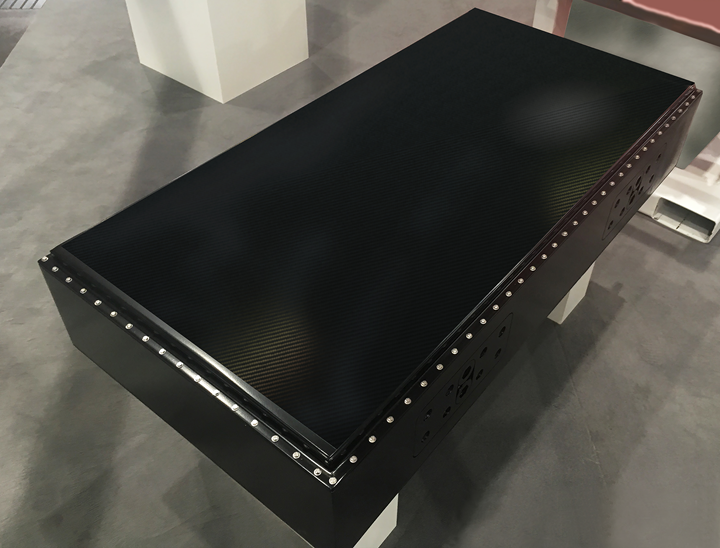

The complete enclosure. After the top and bottom panel are assembled onto the rest of the frame, the battery enclosure is ready for use by the customer. Source | TRB Lightweight Structures

A few years later, TRB began working with a much larger global Tier 1 supplier in the truck and bus industry. Given the success of the EP9 battery enclosures, TRB was again approached to take on the challenge — but this time, with a long-term supply agreement for a volume of tens of thousands of units per year.

Planning, material selection and design

The initial focus for the battery enclosure was weight reduction, Dugmore says. Before TRB became involved, the bus manufacturer had begun work internally on design for a battery enclosure, with plans for an aluminum top cover and bottom cover. This metal design though, proved too heavy.

Each electric bus features up to six, 74-kilowatt batteries, each weighing 550 kilograms including the battery enclosure. To meet overall weight requirements, the weight goal for the battery enclosure was only 15 kilograms. The aluminum enclosure weighed 64 kilograms. “It’s quite a reduction in weight, which then really pushed us towards the composite materials as opposed to aluminum or other metals,” Dugmore says.

Space was also a factor: the battery enclosure needed to be 2 meters by 1 meter in size, and the enclosure could not deflect more than 1 millimeter in any direction due to space restrictions in the bus chassis. “We didn’t have a lot of room to play with,” Dugmore adds. “The space requirements that they had within the battery [space] itself were very tight.”

In April 2018, TRB held a kaizen event — a five-day brainstorming event — to learn more about the enclosure requirements and to develop material and process solutions that met these needs. A variety of fiber reinforcement and resin suppliers attended the event, as well as representatives of the end customer. By the end of the week, TRB had several material options to present.

The company needed a composite material that met the customer’s fire, smoke and toxicity (FST) requirements, was able to cure quickly and also fell within the target price range. None of the prepreg options TRB evaluated from other suppliers met all of the requirements — at least not cost-effectively for the volume.

As a result, TRB “decided that we could actually use our own knowledge and IP [intellectual property] that we built up over many years and manufacture the material ourselves,” Dugmore says. The company developed a proprietary, industrial-grade, snap-cure epoxy resin system that meets the customer’s specific FST requirements. Combined with a high areal weight carbon fiber, the prepreg is said to cure within 2 minutes.

After material selection was completed, TRB entered a rapid prototype manufacturing phase, going through four design iterations. “We had to go back to the start, since the original design was optimized for a metallic component,” Dugmore says. “We completely redesigned it.”

Dugmore explains that the original design for the bottom cover was for a flat panel comprising a metallic honeycomb structure. In transitioning the design to composites, TRB was able to reduce the overall skin thickness of the panel while also adding shape in the form of molded-in internal ribs. “[The ribs] added a lot more rigidity to the part, and meant we could reduce the skin thickness even more,” Dugmore says. Overall, base cover thickness was reduced from 14 to 4.5 millimeters; top cover thickness was reduced to just more than 2 millimeters. “The base is thicker and stronger to bear the weight of the battery,” he explains. “The top cover is essentially a lid … and there is a slightly different design and material selection because of it.”

New facility, new automated process

Aside from the design of the component itself, two major challenges to the project, Dugmore says, were that the customer required all of its bus components be manufactured in the United States, and that traditional hand layup would not be adequate to meet the goal of 40,000 units per year.

As a solution to the location requirement, TRB constructed a purpose-built manufacturing facility in Richmond, Ky., U.S. in a joint venture with Toyota Tsusho America (New York, N.Y., U.S.), specifically for high-volume production of carbon fiber composite components.

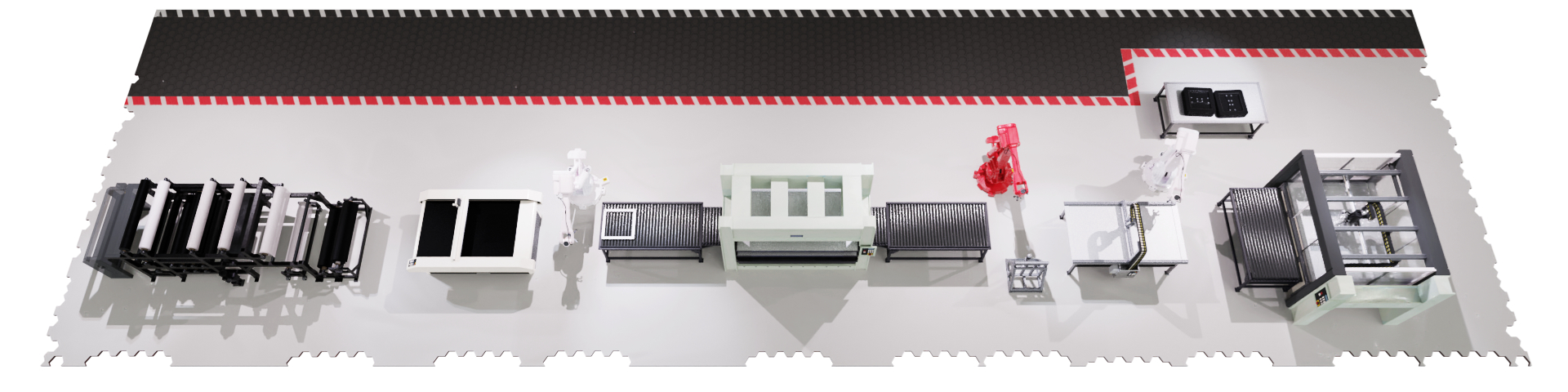

New, automated production line. TRB’s FPC production at its Richmond, Ky., U.S. facility processes the material from prepreg to finished part, leveraging robotic automation and prepreg manufacturing expertise. Source | TRB Lightweight Structure

TRB also leveraged its innovative new automated press cure process developed specifically for thermoset materials. “We have a strong history in terms of press manufacturing in both aluminum and composite,” he explains. “We have focused a lot of our energy on that, and we developed a system that we call FPC, or fast press cure.”

The FPC process is designed for speed and automation, using robotics and a heating system that cures a part in minutes compared to an hours-long manual process; this specific part is said to take 11 minutes from mold open to mold open.

The process is vertically integrated. The carbon fiber fabric is impregnated with the aforementioned specialty resin system, and then the prepreg is cut and pulled onto a matched metal tool by automated pick-and-place robots for cure through the FPC process. The part is then robotically machined and assembled per customer specification, including deflash, bonding of inserts and gasket placement.

“Essentially, fabric goes in one end and a finished component goes out the other end,” Dugmore says. “But what’s unique about this is that we’re actually manufacturing material for our own usage and not for distribution,” he adds, “which is very different from material manufacturers.” One benefit of this is that the prepreg is made directly for use within minutes, which eliminates the time, equipment and packaging needed to store or freeze the prepreg.

In addition, according to the U.K. Department of International Trade, for some components of its battery covers, TRB is using a sugar-based resin that is 100% derived from agricultural waste biomass, shipped from its U.K. facility.

The new resin system enables new opportunities, as well, according to Sandra McQueen, chief marketing officer at TRB. “You have the ability to tweak the resin system in real-time, as you produce test parts, which means we can ensure it meets the requirements of the application. You’re also able to control the supply chain, which allows you to move faster and potentially decrease cost. These decisions and many more help unlock the possibilities for high-volume composites.”

Approaching serial production and beyond

During the alpha testing stage, the prototype covers were built and tested against FST and deflection requirements. The prototype stage was rapid, Dugmore says — prototyping and testing were done in parallel, with one iteration undergoing testing even as another iteration was under development. The final iteration included the addition of plies to the bottom cover for thermal insulation, electrical insulation and EMI shielding.

The alpha stage was followed by a beta manufacturing stage, with the expectation of going into full production by the first quarter of 2021.

Dugmore adds that TRB is in discussions with other potential customers about applying the new epoxy prepreg and FPC process in other enclosure applications. TRB’s goal is to position the U.S. facility for more mid- and high-volume battery enclosure projects going forward. The company also plans to add additional automated lines to the facility as it brings on more customers.

Related Content

Aptera expands presence of solar electric vehicle into UAE

The UAE will provide an ideal environment to introduce the company’s solar-powered composites-intensive BinC vehicle internationally.

Read MoreEnvalior offers novel Tepex composite for EV battery housings

Low-thickness, recyclable thermoplastic composite passes strict thermal runaway tests for EV battery housings.

Read MoreExel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.

Read MoreSeat frame demonstrates next-generation autocomposites design

Light weight, simplified/cost-effective manufacturing, passenger comfort and safety informed materials and process innovations and won awards for the 2022 Toyota Tundra‘s second-row seat frame.

Read MoreRead Next

TRB Lightweight Structures to open U.S. manufacturing facility

The facility in Richmond, Ky. will focus on high-volume production of automotive components using TRB’s robotics-assisted press-forming process.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)