Fold-to-form CFRP battery boxes, HP-RTM wishbones

Williams new EV platform demos 223 composite forming process and £20 suspension arms using recycled carbon fiber.

Williams Advanced Engineering (WEA, Grove, Oxfordshire, UK), a sister company to the F1 team, offers its expertise to industry in areas including aero- and thermodynamics, advanced lightweight materials, including composites, and hybrid/electric vehicles. Its EV pedigree includes being the sole battery supplier for the Formula E racing series, the team behind the Jaguar CX-75 hybrid concept car and all of Nissan’s electric vehicle prototypes, the technology partner for the 2020 electric hypercar being developed by Singapore startup Vanda Electrics, developer of a high-performance battery project for VW Audi and leader of a consortium including Coventry University, Unipart, WMG, and Productiv, in the development of a UK flexible battery manufacturing facility.

According to The Engineer UK’s interview in May 2017 with WEA technical director Paul McNamara, the company had about 48 projects underway, mostly motorsport and automotive, but also some further afield, including an aerodynamic device that reduces the energy consumed by supermarket refrigerators and the lightweight, crash-proof carbon fiber composite Baby Pod, designed for transporting babies from one hospital to another.

Although OEMs including Mercedes-Benz, Volkswagen, Jaguar Land Rover (a Williams client) and Tesla have already come up with their own scalable EV platforms, WEA’s new FW-EVX offers more power and range at less weight and is a brilliant piece of elegant design and systems integration. Plus, it features some very cool composites technology. The overall result, according to several auto industry writers, is summed up well in a Road & Track article by Máté Petrány: “Tesla's aluminum platforms just don't look as cutting-edge anymore.”

The increasingly popular idea of scalable EV platforms is illustrated in the YouTube video below for “Faraday Future’s revolutionary Variable Platform Architecture”.

CFRP skateboard chassis

The FW-EVX is a scalable, modular platform, ready to be used by an existing or start-up car brand. Its “skateboard configuration” chassis houses 38 battery modules, twin independent YASA electric motors and Xtrac transmission in the rear, one YASA motor and Xtrac differential in the front, and wishbone suspensions for all four wheels. Power, range and vehicle size can be scaled up or down from the 2800mm wheelbase by adding or subtracting battery modules.

The chassis with batteries, motors, electronics, wheels and tires weighs 955 kg. WEA says with lightweighting, an EV the size of a BMW M4 would total 1750 kg — 400 kg lighter than a Tesla Model S. And more powerful. With three motors, power totals 480 kW, equivalent to 652 bhp. This reportedly exceeds the top-end Tesla Model S P100D, which normally weighs in at 2241 kg. WEA says the FW-EVX can go 552 km with just an 80 kWh battery, which again exceeds the Tesla S P100D at 507 km, though the longest range S model can reach 572 km.

|

Hollow CFRP side sills contain aluminum fins (left) that channel cooling air from the front crush-can structures (twin projections at far right) to cool the batteries.

SOURCE: WEA and TheEngineer.co.uk

This performance, says Paul Horrell in a topgear.com article, comes from system integration: “Like a racing car, everything has been designed to work together.” The skateboard comprises a long, wide but thin (250-mm) carbon fiber reinforced plastic (CFRP)-clad battery compartment between two hollow, load-bearing CFRP sills. The sills co-depend on the battery modules inside the compartment for structure. Most EVs house each battery module within the battery compartment in its own aluminum box. Instead of 38 aluminum-boxed batteries, the FW-EVX uses CFRP boxes, which not only cut weight but also boost damage resistance. In return, the sills have less protective work to do, so they’re made lighter as well.

The sills also serve as air-to-water radiators to cool the batteries, eliminating the need for conventional radiators. Inside their CFRP shells are series of lightweight aluminum fins. Air is drawn into the sills through the front crash-can structures and passes over adjacent water channels. The cooled water is fed from one sill under the battery modules to cool them while from the other sill it cools the car’s power electronics. The forced air in the sills also circulates around the battery modules and exits through a rear diffuser structure, enhancing downforce. The fins also work as crumple zones, absorbing energy in the case of side impact.

Though the battery modules have a wired connection to the electrical system busbar, their communication with the control system, managing temperature and charge, is wireless. The overall design is a much lighter, simpler assembly vs. EV norms.

The FW-EVX standard rolling chassis is powered by 38 battery modules, each battery housed in a battery box made from CFRP vs. aluminum. SOURCE: WEA and Motortrend.

Foldable, CFRP battery boxes

So here I’m going to admit that I’m making an educated guess about the battery boxes. Some of the auto industry articles say this 223 technology is for the overall battery “box”, what I’ve called the battery compartment. Others say it’s for the individual battery boxes, which are also called battery modules. I’m going for the latter. If you look at Iain Bomphray’s comments below, he says the battery box is deep and it would be hard to push prepreg into the corners. Well, the chassis box/battery compartment is only 250mm. I’ve seen plenty of 10-inch deep CFRP boxes. The battery modules, however, which are aluminum in most EVs, are only 136mm wide. Making 38 different 5-inch by 10-inch boxes using prepreg and a mold would indeed not be my idea of fun. Not impossible, just not as easy as folding them. That being said, I think the 223 technique could also be adapted for the larger battery compartment. The article and pictures on Autocar.com (see below) push hard for this scenario. I’ll update you when I get a response from the top techs at WAE.

(See my links to folded, hinged composites and more eye candy from Autocar.com at the bottom of this blog.)

One more note about the smaller battery module boxes. The FW-EVX uses LG pouch-type battery cells, 10 cells per module, 38 modules per standard chassis. The Engineer article mentions that each pouch cell is encased in a polymer foam structure for vibration protection and thermal insulation. Another article talked about honeycomb being used in some of the CFRP structure.

The long, wide and thin (250mm) FW-EVX CFRP battery compartment box (left)

vs. small battery module CFRP boxes above. SOURCE: Autocar

The manufacturing process that WEA dubs “223” describes its ability to efficiently transform a 2D composite laminate into a 3D box structure. Here, I’m going to pull from The Engineer UK article written by Stuart Nathan:

“This is easiest to imagine as a way of making carbon fiber boxes by opening them out into a flat structure that is simpler to make. The areas of this flat structure corresponding to the faces of the box are cured while leaving the borders between each face flexible, forming hinges that allow the flat structure to be folded into a box, before the whole item is cured to rigidity.

This solution is suited for deep but narrow boxes such as the battery housing. Technical specialist Iain Bomphray said ‘You could technically make them by the conventional manual lay-up technique – building up layers of resin-impregnated carbon fiber fabric on a tool by hand, then curing them. But because the box is so deep, this would require considerable hand-skills to get the layers in, and it would take ages to build each box.’

The aerospace sector generally uses robotics to lay up such structures, as The Engineer has reported, but this also tends to be very slow. WAE is discussing the development of 223 for ‘several nonautomotive applications’, Bomphray said.”

SOURCE: Motortrend.com (left), TheEngineer.co.uk (right)

Recycled carbon fiber, HP-RTM wishbones

The second technology which I think has extremely interesting implications is a high-pressure resin transfer molding (HP-RTM) process called Racetrak, developed by WEA in collaboration with the National Composites Center (NCC, Bristol, UK). It reportedly uses oriented fibers in a loop and can produce components made of 80% recycled carbon fiber (rCF) by weight.

According to Williams Advanced Engineering’s communications department, the composite wishbones are 40% lighter than a conventional aluminum wishbone but at comparable cost. Reportedly, it is the highly automated, near zero-waste process that can be scaled for mass production that enables cost parity between CFRP and forged Al. WAE’s Bomphray says a standard composite press — standard HP-RTM press perhaps? — can turn out 500,000 wishbones per year. They can also be made with embedded bearings, bushings and wireless sensors.

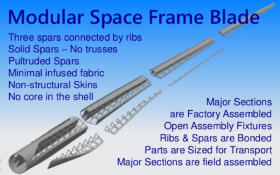

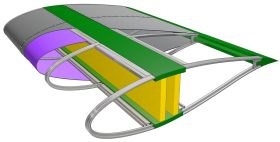

The Racetrak process is patent pending, and reportedly already in development at Vestas for use as wind blade ribs, over which a technical fabric “sock” would be pulled for a stressed skin construction (space frame/tension fabric). Now that could have some interesting weight and cost implications. Note that the MHI Vestas advanced manufacturing facility on the Isle of Wight, UK (a 3-hr drive south of WEA) manufactures its 80m blades.

GE was part of an ARPA-E project in 2013 looking at this same basic concept. Texas-based Wetzel Engineering announced in 2015 that it would test the field-assembled, 62m-74m long “SparBladeTM” concept, featuring a lightweight bonded composite spaceframe. Funded by the National Renewable Energy Laboratory (NREL) in partnership with the Electric Power Research Institute, Wetzel worked in collaboration with Northern Power Systems, TPI Composites and NextEra.

|

SOURCE: GE and BusinessWire.com (left), Cleantechnica.com (right).

Future for FW-EVX – applications at Airbus?

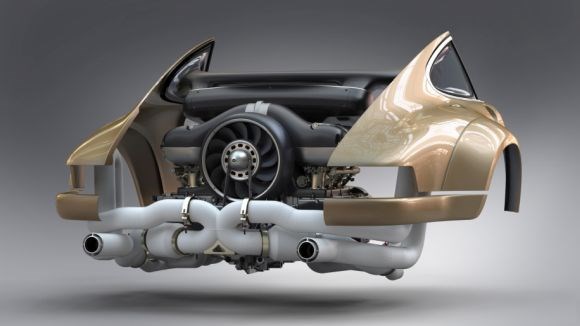

Unveiled in September 2017, WEA announced it was looking for partners to further develop and test the VW-EVX platform. WEA technical director McNamara said Williams could build roughly 100 per year in its composites, machining and battery workshops, which are busy through the winter fabricating next season’s F1 and Formula E components, but have capacity in summer. And in case you thought the company has completely jettisoned fossil fuel technology, WEA is also working with Singer Vehicle Design (Sun Valley, CA, US) to lightweight a modified air-cooled Porsche flat-six engine featuring a CFRP airbox and fan shroud (see below).

One last thing. WEA and Airbus signed an MOU in December 2017 to examine applications that may combine Williams’ innovation culture, lightweight composites and battery expertise with Airbus‘ Zephyr High Altitude Pseudo-Satellite (HAPS) program. HP-RTM ribs with embedded sensors and solar cell fabric wings anyone?

Porsche 4.0L air-cooled flat-six with 4-valve cylinder heads, showing carbon fiber airbox and fan shroud with CFD-optimized and enlarged fan. Restored and modified by Singer Vehicle Design and Williams Advanced Engineering. SOURCE: Autoblog.com.

Composite hinges and folded composites

https://www.compositesworld.com/blog/post/carbon-kevlar-hinge-

Autocar images. Click here to see more.

|

Related Content

From the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreAirbus selects Airborne to supply automated ply placement system

The pick-and-place system with software-driven automated will be the first in Airbus facilities, enabling highly efficient and flexible dry fiber preform manufacture for A350 structures.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More