Airbus selects Airborne to supply automated ply placement system

The pick-and-place system with software-driven automated will be the first in Airbus facilities, enabling highly efficient and flexible dry fiber preform manufacture for A350 structures.

Airborne (The Hague, Netherlands) has been selected by Airbus (Toulouse, France) to supply an automated ply placement (APP) system to its Getafe production plant, for the automated manufacture of dry fiber preforms for resin transfer molding (RTM) structures — specifically, preforms for the A350 rear fuselage beams and maintenance door frame, made of unidirectional (UD) composite materials and fabrics. This will be the first time a pick-and-place-based system is used in Airbus factories.

Dry fiber composites are an efficient method to manufacture complex, highly loaded primary structure, thus the reason Airbus is using them to produce the A350 rear fuselage beams. First the preforms are made, then shaped into the right 3D geometry by hot drape forming and finally infused with epoxy resin via RTM processes.

Preforming for dry fibers, however, is still manual for many aerospace facilities; according to Airborne, automating the handling of the delicate materials in a robust, repeatable process has proven to be a challenge. Furthermore, the large variety of ply shapes and the combination of several materials into a part is complex with regard to system design and robot programming.

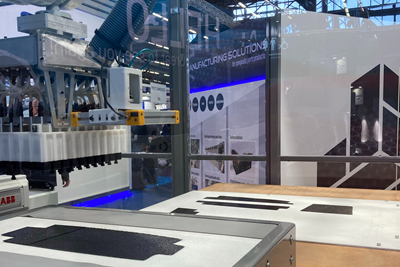

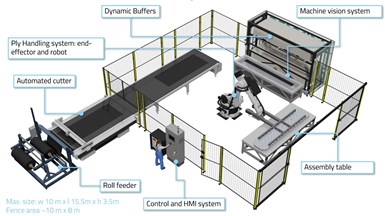

Airborne’s APP technology addresses these difficulties. The concept is to cut the materials into the required shapes, pick them up with a robotized system and place them on a welding table to create the tailored blank preform. To stabilize the laminate, each ply is fixed in place by spot-welding, which activates the binder in the material. To minimize waste, the system has a dynamic buffer where the plies that are not needed yet can be temporarily placed — this way, the nesting can be optimized. It also enables the combination of different materials into one laminate, by storing the plies until all required materials are cut and available. The system is equipped with a vision table, that can check the quality of the cut plies and increases the accuracy of placement to the required level.

The preforms have a maximum size of 3.5 meters. Airborne will enlarge the size of its standard system to accommodate these large plies.

To handle the processing of different ply shapes, Airborne incorporates Automated Programming into all of its machines, which avoids the need for robot programming. The software takes the ply design and material input, and translates this via an advanced algorithm into the correct robot motions and process parameter settings on-the-fly.

This approach of software-driven automation makes the systems flexible. The user can easily upload new nest files, ply shapes or laminate definitions and the system will adapt automatically. It provides the customer the possibility to adapt to changing operational needs (for example by using dynamic nesting) or to new product designs.

In this project, Airborne will further develop its APP system to Airbus requirements, test and install the system in the factory, before handing it over to the aerospace company. An extensive trial period is included in the project, to ensure the system can reach the required accuracy and robustness that is needed for the highly loaded and critical primary structure components. Airbus will support Airborne and qualify the technology to be used according to its standards.

“We are proud to be able to supply Airbus with our automated ply placement technology,” Marcus Kremers, CTO of Airborne, says. “It is great that our vision on creating new methods to automate composite manufacturing is shared and that we can bring this technology into the heart of Airbus composite manufacturing in the Getafe plant.”

APP is a result of years-long R&D investment of Airborne, supported by several government funded programs such as TAPAS, Innovatiekrediet and the Dutch Mobility Fund. The development of this project is planned to be part of the Dutch Growth Fund program.

Learn more about Airborne’s part in delivering an upper stage tank for the EU ENVOL project, or its collaboration with Accudyne to deliver automated composites solutions worldwide.

Related Content

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreA new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Techni-Modul Engineering grows automated technologies for composite part manufacture

New processes and approaches for kitting, stack and layup continue to be in high demand for composite industry OEMs, which TME backs with its SMART Control technology.

Read MoreLimosa taps Airborne composites expertise to build LimoConnect

Airborne’s capabilities will support airframe prototyping, automated production of the Limosa LimoConnect eVTOL + eCTOL aircraft from prototype through to serial production to help meet 2028 entry-into-service goals.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)