Generative design and continuous 3D fiber deposition

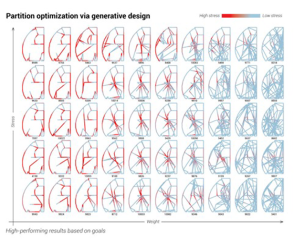

Generative design replicates nature’s evolutionary approach by combining artificial intelligence (AI) and cloud computing to provide thousands of solutions to one engineering problem.

Generative design replicates nature’s evolutionary approach by combining artificial intelligence (AI) — specifically advanced optimization algorithms — and cloud computing to provide thousands of solutions to one engineering problem. “This is no longer drafting, but instead describing the design problem by communicating constraints,” explains Massimiliano (Max) Moruzzi of Autodesk Research's Computational Science group (and self-proclaimed advanced material manufacturing evangelist). Here are some of the projects Autodesk is supporting:

|

|

|

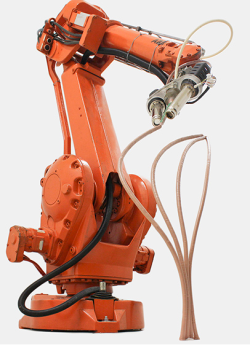

MX3D Resin (top) and MX3D in metals |

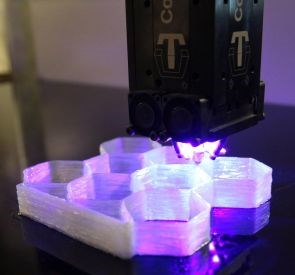

Continuous Composites, Autodesk and Comau have printed continuous fiber thermoset in-situ honeycomb and self-supported bridging structures composites (e.g., epoxy) SOURCE: Autodesk |

“Generative design offers a much broader range of optimization and design possibilities,” says Moruzzi.

Instead of starting with a drawing or preconceived geometry, you define the problem you want to solve — loads, spatial constraints, materials, manufacturing methods, cost constraints. The generative design software then explores all of the possible permutations, generating numerous design alternatives, testing and learning from each iteration. You choose the design that best fits your requirements.

Generative design is “the next generation of CAD”. Moruzzi explains, “Using high-level math and a set of different optimizers, we have created a new way to define geometrical shape based on numerical synthesis. CAD systems today are still just digital drafting. But with generative design, we have achieved more or less what Leonardo Da Vinci suggested: ‘a problem well-constructed provides optimized solutions’. We now focus on describing the solution we want. So it is a goal-driven process and platform which enables the engineer to synthesize the entire design space.”

One result of this paradigm shift, he notes, is that shape and functionality are included in the structure. “The material is one part of this,” Moruzzi contends. “Material previously functioned to support whatever geometrical objective the designer was aiming for. But with generative design, we now add in the manufacturing process and material into the design so that both will now form part of the analysis for optimal geometrical shape.”

Smart structures

As Autodesk began developing generative design, Moruzzi says it sparked a journey into advanced manufacturing. “We are focusing on technology which can incorporate advanced materials and smart materials to capture the full benefits of generative design.” He asserts that fiber-reinforced composites have matched isotropic materials like steel and aluminum and are now surpassing them because composites can embed functionality. “But we don’t fully understand the complexity of these materials, so we use failure criteria that are restrictive. The result is that we force composite materials into a shape. But to be fully optimized, the material should follow both structural and functional loads — such as magnetic shielding, temperature gradient, vibration, etc.”

|

Autodesk worked with Airbus to create the “bionic partition” for the A320 using generative design and metallic 3D printing. A significant amount of Autodesk’s work has been in metals, but Moruzzi sees the future in fiber-reinforced composites. SOURCE: Autodesk.

Moruzzi sees that fiber-reinforced composites and generative design are symbiotic, helping each other to actualize and expand. “Today we define the physics and the material properties of the composite and then we use FEA to solve the design problem,” he explains. “But this is backward. Nature does not create the tree and then the wood.” Generative design matches nature’s process, and, in turn, enables composites to as well. “Now the material and its placement can be driven by the structural loads and functionality,” says Moruzzi. “This will lead to new functional materials and augmented manufacturing processes.”

However, Moruzzi asserts that, until now, there has not been an automated process for placing fiber-reinforced composites that could embed function into the part easily. He says this having designed automated fiber placement (AFP) systems in the past, working for Ingersoll in the early 2000s with companies like Boeing, Lockheed and the Lamborghini Lab in Seattle, WA. His projects with companies like MX3D and Continuous Composites are part of a strategy to demonstrate what is possible to industry leaders and OEMs. “Through these projects, we can take the benefits of anisotropy to a different level. It is not just a matter of actualizing bionic and biomimetic shapes. The goal is to create living structures with a nervous system that can sense and communicate, the real potential for smart aircraft, cars and buildings These aren’t possible with traditional metals.”

|

|

SOURCE: Continuous Composites and Autodesk.

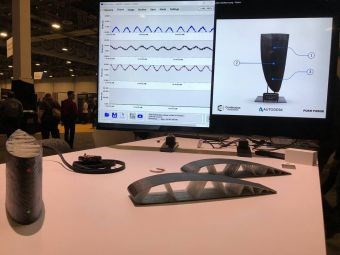

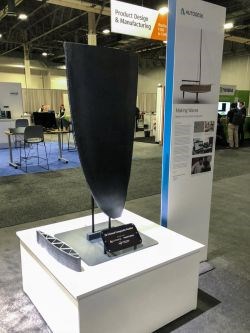

Sensors printed in the rudder exhibited by Continuous Composites at AutoDesk University 2017 collected 5 Gigabytes of data over 2 days, tracking temperature, acceleration and stress changes from attendees touching the structure. (Read more in my blog on Continuous Composites.) MX3D is also printing structures with embedded sensors.

“I started to present a vision for 3D printed composites because you don’t need tooling, you synthesize the part,” says Moruzzi. “Continuous Composites can print with continuous fibers, wires and fiber optics, so I can embed a neuro system into the structures. The material is also impregnated on the fly. So this type of manufacturing matches what generative design presents as a solution.”

|

Livrea Yacht will race the world’s first 3D printed yacht in the 2019 Mini-Transat yacht race.

SOURCE: Autodesk

Moruzzi goes even further, explaining that ultimately, this type of advanced manufacturing requires an ecosystem, which includes a supply chain for how these smart structures can be manufactured. “Livrea Yacht is a different part of this ecosystem,” says Moruzzi. Another one of the companies Moruzzi is working with, Livrea Yacht is building the world’s first 3D printed sailboat, which will compete in the 2019 Mini-Transat solo transatlantic yacht race. (For more details read Scott Francis’ blog on this project). “All new technology and advancement requires investment, so it is important to educate about why this investment is worthwhile. You also need to create engagement.” He notes that, traditionally, new materials and manufacturing have generated excitement through race cars, racing boats and spaceships. “Livrea is a racing boat which will cross the Atlantic, it has a very interesting generative design shape which also achieves lightweight, and it is made using 3D printing without a mold. We can use this as a powerful channel to broadcast what is coming with generative design.”

Future of Manufacturing

He claims there are other projects, for example in the construction industry, which he cannot discuss but which will further illustrate the power of what is possible. However, Moruzzi proclaims the future of composites and generative design is not just 3D printing. “And I don’t think we have the final machine yet either,” he adds. “The customer does not want a specific CAD/CAM system or machine. The customer wants a solution.”

Moruzzi says that when he started in composites 15 years ago, he looked at the fabric and textiles industry. “The most advanced structure is the textile itself because it adds functionality as well as structural performance. It can make you hot or cold, it can be elastic or not, it can take a shape or restrict, shrink or expand. You can program it in any way you want.” He sees that the design of weaving machines is going to change. “Right now, it’s limited by a look-up table, so that I am only building a few sets of different designs [weaves]. But we will synchronize the generative design and what the structural textile will be. So generative manufacturing will not just be 3D printing. The other options will be hybrid processes with looming and knitting and adding discontinuous fiber. Then we will start to use even more sustainable materials, including biomaterials and spider silk. There is a huge hybrid machine movement coming. You can then synthesize your dream by pushing a button.”

There is also a path forward where the systems collaborate to continuously improve. “With the generative design approach of computing the design space instead of drawing a single design concept, when you change anything, it’s not another FEA iteration because the space is already fully computed,” Moruzzi explains. Machine learning is already being integrated into composites manufacturing systems. This will enable lessons learned to be fed back into the generative design software for application to future iterations of the design.

(This concept was discussed in my blog on the production lines being developed for thermoset composites in the ZAero project and by Airborne, SABIC and Siemens for thermoplastic composites.)

Full disclosure, there are other generative design platforms out there. Dassault Systèmes actually discussed “Functional Generative Design” in its 2016 column for CW, “Increasing the industrial adoption composites additive manufacturing”.

There are also other companies advancing 3D printing with continuous fiber and/or sensors including:

- Anisoprint (Russia)

- Arevo

- Carbon Factory at ETH Zurich

- MarkForged

- McNair Center, University of South Carolina

- moi composites

- Orbital Composites

- Shanghai University

- Tokyo University of Science and Nihon University

http://www.jscm.gr.jp/3Dprinting/images/introduction_CFRP3Dprinter.pdf

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More