GKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

Headquartered in Redditch, Worcestershire, U.K., GKN Plc’s Aerospace Division continues its strong growth, based to a large extent on its expertise in the production of composite structures. Even the 50 percent of the business that is not focused on composites is based primarily on materials technologies, such as complex titanium aero-engine components and cockpit canopies with vacuum-deposited surfaces to enhance stealth performance. This should not come as a surprise, because GKN’s first use of materials technology to gain market share was in the 1860s, when it dominated the railroad supply business by being the first company in the U.K. to make steel by the cost-effective Bessemer process. The company produced more than 56 million lb (25,400 metric tonnes) of steel per year by 1871.

As GKN Aerospace has expanded its business, it has acquired companies outside the U.K. By the end of 2008, more than half its business was conducted in the U.S. In 2009, it restored the balance between its European and American operations by buying the Airbus manufacturing operation at Filton, U.K., for £136 million/$210 million (USD). Not content with this large acquisition, GKN committed to invest an additional £125 million/$192 million to develop Filton as a global Center of Excellence in composite wing structures. This decision was a result of GKN’s selection as a participant in the Airbus A350 XWB program.

A350 rear spar program

GKN has been awarded a contract under which it will supply fully assembled rear spars for the A350. Chris Gear, GKN’s VP and chief engineer, explains that the company’s role is to be the designer, integrator and supplier of rear spars that are prefitted with all the trailing-edge assemblies. GKN has overall responsibility for delivering the assembly, but Airbus has selected the suppliers for many of the components. For example, GE Aviation Systems will manufacture many of the components in the trailing edge at its facility in Hamble, Hampshire, U.K.

A significant number of trailing-edge panels will be made in an out-of-autoclave process, using Advanced Composites Group’s (ACG, Heanor, Derbyshire, U.K.) oven-curable MTM 44-1 prepreg system — the first time this technology has been used in a major production application. (For more on this and other out-of-autoclave resin systems, see HPC’s feature article in this issue, titled "Out-of-Autocalve Prepregs," under "Editor's Picks.") GKN will be responsible for making the 30m/97-ft long spars in three sections and then attaching all the frames, rib posts, undercarriage attachment fittings and other accessories to each spar section.

Fig. 1 shows the demonstrator inner rear spar. The height of the spar at the root end is nearly 2m/6.5 ft and tapers to about 0.25m/10 inches at the wingtip.

After the components are attached to the spar sections, the joints between the sections are completed to create the entire rear spar subassembly. Then the subassembly is broken into three parts, each about 10m/32-ft long, for ease of transport to the final wing assembly line in Broughton, located on the Wales/England border.

The design responsibilities flow down the supply chain. GKN uses Airbus methods and design tools to calculate the stresses and strains in the rear spar and trailing edge assembly. Airbus then is responsible for the integration of components from GKN and other manufacturers into the wing. The main loads in the spar come from the wingskins. These loads are derived from the Airbus global finite element model for the wing. Additionally, there are landing loads from undercarriage attachments that connect to the spars as well as fuel loads, which include both the weight of the fuel itself and sloshing loads when the fuel tank is partially empty. GKN must analyze all of these load types when designing the composite spar.

Airbus requires that spar manufacturing methods involve the use of an automated fiber placement (AFP) machine. GKN will use AFP equipment supplied by MTorres (Torres de Elorz, Navarra, Spain).

GKN already had developed a production method for wing spars, used to lay up spars for Airbus Military’s (Madrid, Spain) A400M transport plane. However, this method was not practical for the A350 spars. Briefly, the method involves high-speed tape laying of a flat laminate, followed by hot drape forming of the material into the C-section of the spar. (Read about the A400M wing spar forming method in “Composite wing spars carry the Western world’s biggest turboprop engines,” under "Editor's Picks," at top right). At first sight, the forming appears to be comparatively simple, but a close examination of either spar reveals many padded areas where attachments, such as flap track beams and ribs, are secured. These buildups require that the laminate allows for complex inter- and intraply slippage during the drape forming process. This is possible using Cytec Engineered Materials’ (Tempe, Ariz.) Cytec 977-2 prepreg selected for the A400M, but such movement is not possible with the more sophisticated Hexcel M21E prepreg (Hexcel Corp., Dublin, Calif.) chosen by Airbus for all structural parts on the A350.

Two spars, of opposite hand, are made at one time on a CFRP mandrel mounted on the AFP machine. The layup is then cut in two — for the port and starboard spars — and transferred with vacuum devices to male Invar tools for curing. The spars are then machined in an automated robotic cell supplied by Brötje Automation GmbH (Wiefelstede, Germany). The cell drills all the holes and trims the spar edges. It also machines the outer surfaces of the spar caps to a close tolerance because the positions of the surfaces are critical for controlling the depth of the wing.

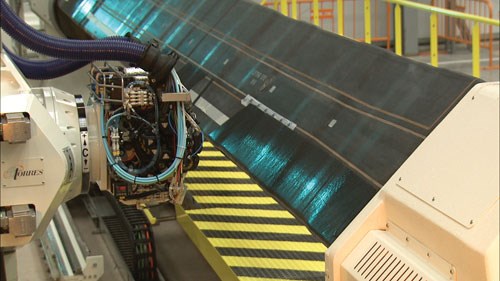

Prototype parts were made on GKN’s first AFP machine while it was still at MTorres in Spain. Since then, that machine and a second one have been installed at GKN’s dedicated spar facility, which is now taking shape at Weston Approach, about eight miles from Filton. All the spar manufacturing operations — lay up, curing, machining, nondestructive testing and assembly — will take place at this location. Eventually five AFP machines will be installed to meet the need for 10 shipsets per month. (Fig. 2 shows a GKN AFP machines undergoing trials.)

This type of work is very important to both GKN and Airbus and signifies the revolution that is taking place in the aerostructures supply chain. GKN expects the contract to enhance its position as a structural integrator rather than a maker of parts. At the same time, it is part of Airbus’ effort to simplify its assembly operations by delegating many former responsibilities to a new generation of “Super Tier 1” suppliers.

Related Content

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MoreRead Next

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

Read MoreComposite wing spars carry the enormous turboprop engines

Airbus A400M aircraft prompts new spar design and new manufacturing system designed to make it.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)