IACMI Winter Meeting: Mapping the road ahead

The Institute for Advanced Composites Manufacturing Innovation (IACMI) held its winter meeting in Denver Feb. 1-2, updating its membership on the public-private institute's efforts to accelerate composites design and manufacturing.

Share

Read Next

Fabrication of the 9m experimental wind blade at IACMI's Composites Manufacturing Education & Technology (CoMET) facility at the National Renewable Energy Laboratory (NREL) in Golden, CO. The blade uses thermoplastic resins and foam core made with recycled PET.

The Institute for Advanced Composites Manufacuring Innovation (IACMI, Knoxville, TN), or The Composites Institute, held its winter membership meeting in Denver, CO, Feb. 1-2 and provided an update on activities of the public-private US Department of Energy consortium, which is accelerating material and processing technologies to help make composites manufacturing more efficient and less expensive. About 300 people attended the meeting.

First, the day before the meeting, IACMI officially opened its Composites Manufacturing Education & Technology (CoMET) facility at the National Renewable Energy Laboratory (NREL, Golden, CO). There, it unveiled a 9m demonstrator wind turbine blade designed to prove the efficacy of the application of materials that are not commonly used in wind blades.

The blade uses materials from industrial partners Arkema Inc., Johns Manville, TPI Composites Inc., Huntsman Polyurethanes, Strongwell, DowAksa USA, Chomarat North America, Composites One, SikaAxson, Creative Foam and Chem-Trend. Pultruded carbon fiber spar caps for the blade were fabricated at Strongwell in Bristol, VA, and shipped to Colorado for incorporation into the blade shells. The new blade, molded on tooling supplied by TPI Composites, features innovations such as impact-resistant components, continuous fiber-reinforced thermoplastic parts and exterior shell components produced with less than half the normal CO2 emissions commonly emitted in wind blade manufacture.

These innovations can be deployed in the near term in existing blade manufacturing plants,” said Derek Berry, IACMI’s Wind Technology Area Director. “The ability to infuse at room temperature, demold more quickly, and avoid post cure, plus use of low cost carbon fiber spar caps produced via high-speed pultrusion, all contribute to reductions in the levelized cost of energy, the key measure of wind turbine efficiency.” The blade will next undergo physical testing to assess material performance.

At the meeting, the wind theme continued with a presentation by Jacques Nader, who manages global wind blade design R&D at wind turbine manufacturer Siemens. He noted that as onshore blade lengths increase, wind blade manufacturers will face ever-more daunting challenges associated with the fabricaiton of large composite structures, not the least of which are manufacturing speed, quality control and material use efficiency. He noted that a turbine with a rotor diameter of 154m has a swept area as large at 4.5 football fields and is now expected to withstand 100 million cycles over a 25-year life span. Looking forward at future wind blade innovation, Nader says to expect advances in leading edge erosion, testing regimes, transportation, maintenance and manufacturing automation.

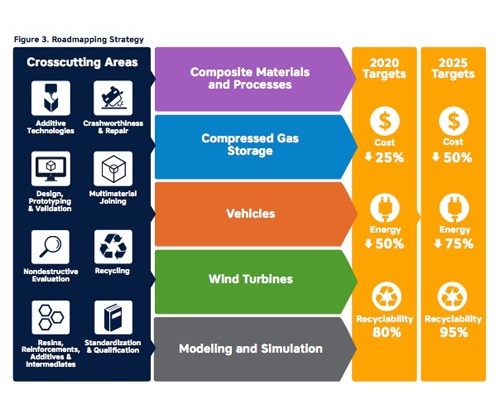

Broad overview of the IACMI roadmap.

Uday Vaidya, chief technology officer at IACMI, presented to the membership the technology roadmap that will provide overall guidance of IACMI's funding efforts through 2020. IACMI's broad goals are, by 2020, to reduce the cost of carbon fiber by 25%, reduce energy consumption in composites manufacturing by 50% and increase composites recyclabilty by 80%. Vaidya listed a series of cross-cutting topics into which funding will fall, and which are aligned with the roadmap. As illustrated above, the crosscutting areas are additive technologies; design, prototyping and validation; nondestructive evaluation; resins, reinforcements, additives and intermediates; crashworthiness and repair, multimaterial joining; recycling; and standardization and qualification. These will feed one of the five primary focus areas of IACMI: Composite materials and processes; compressed gas storage; vehicles; wind turbines; and modeling and simulation. More detailed maps show what will be explored in each of these content areas. The full roadmap is available to IACMI members; the public IACMI technology roadmap can be downloaded here.

Uday Vaidya, CTO of IACMI, presenting the institute's technology roadmap.

Dale Brosius, chief commercialization officer at IACMI, updated the membership on development and build-out of facilities the group is standing up. These facilities will be offered to IACMI members and non-members, to help facilitate and accelerate composites material and process development. The facilities include:

- CoMET in Colorado, for wind blade manufacturing

- The Composites Virtual Factor HUB at Purdue University (Indiana), for design and simulation software

- Oak Ridge National Labs (Tennessee), for pultrusion, induction heating-based molding, recycling, compounding and fiber optic sensor technologies

- Vanderbilt University (Tennessee), for non-destructive evaluation

- University of Kentucky, for fiber spinning and single-filament fiber testing

- University of Dayton Research Institute (UDRI), for resin transfer molding, pultrusion, prepregging, stitched preforming, additive manufacturing and rapid curing technologies

- Corktown (Detroit, MI), for compression molding, injection overmolding, prepreg layup, high-pressure RTM and testing

- Composite Prototyping Center (CPC, Plainview, NY), an IACMI partner facility, devoted to workforce development, in-situ thermoplastic cure and automated fiber placement

- Composite Recycling Technology Center (CRTC, Port Angeles, WA), also an IACMI partner facility, devoted to composites recycling research, development and manufacturing

Of all of these facilities, the centerpiece will be the Corktown facility. When it's fully operational, in late 2017 or early 2018, it will feature a large Schuler compression molding machine, a 3500-ton Milacron injection molding machine and other equipment that likely will be employed to help accelerate the application of composites in automotive parts and structures.

Brosius also talked later in the meeting about how IACMI will measure the progress of its funding programs. Of primary concern is the fact that progress must be measured against something, which requires establishment of baselines. Brosius looked specifically at the embodied energy and cost to manufacture parts and structures for vehicles, pressure vessels and wind blades, as of June 2105, when IACMI was launched. In wind, he said, manufacturing a 61.5m, 12.2-ton blade via VARTM takes, on average, 1,113 man-hours and costs $15.58/kg, with materials accounting for 64% of the total cost.

A composite part for automotive is more variable, depending on part size, type, complexity, tooling, cycle time, etc. Brosius looked at manufacturing data for four parts: a floorpan, two door inner panels (one glass fiber, one carbon fiber) and a hood inner. Unit cost for these range from $25.45-$82.97/kg, and, again, materials account for most of each part's cost.

For pressure vessels, Brosius evaluated Type IV vessels, which consist of carbon fiber overwrapping a polymeric liner. He calculated costs for three tank varieties: a 64.4L natural gas tank for passenger vehicles; a 538L natural gas tank for heavy trucks; and a tank containing 5.6 kg of H2. As with the wind blade and auto parts calculations, materials represented the largest cost factor. Unit cost for each tank type was $35.42/kg (H2), $65.52/kg (64.4L) and $34.08/kg (538L).

Finally, Brosius also calculated the embodied energy intesity for each part studied. They were: 131 MG/kg (wind blade); 1,273 MJ/kg (floorpan); 610 MG/kg (carbon fiber door inner); 94 MJ/kg (glass fiber door inner); 1,409 MJ/kg (hood inner); 777 MJ/kg (pressure vessel).

Related Content

Novel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreJEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MorePolar Technology develops innovative solutions for hydrogen storage

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More