Polar Technology develops innovative solutions for hydrogen storage

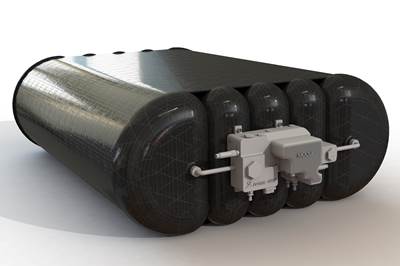

Conformable “Hydrogen in a Box” prototype for compressed gas storage has been tested to 350 and 700 bar, liquid hydrogen storage is being evaluated.

Source | Polar Technology Management Group

Polar Technology Management Group (Eynsham, Oxfordshire, U.K.), an engineering business specializing in both metallic and composite technology, has a wealth of experience in the design, development and manufacture of technologies to support the “H2 economy.” Leveraging expertise in lightweight, composite high-pressure cylinders and hydraulic accumulators, and also key developments in the area of cryogenic liquified gas storage down to liquid helium temperatures (-269°C), Polar Technology has developed composite solutions for compressed gas (CGH2) and liquid (LH2) storage.

These solutions have been focused on three main areas:

- Lightweight cylinders offering industry-leading gravimetric efficiency,

- The novel “Hydrogen in a Box Solution” where volumetric efficiency and space constraints of high-pressure cylinders are important

- Technologies for the cryogenic storage of LH2.

Polar Technology debuted a prototype of its “Hydrogen in a Box” solution at the 2024 Farnborough International Air Show (July 22-26). This multi-chambered storage vessel is said to offer 25% greater volumetric efficiency than current Type 3 and Type 4 CGH2 storage tanks, enabling a more distributed storage solution with great promise for H2-powered aircraft.

“This is an exciting time to be working on hydrogen storage solutions,” says Kieran Burley, Polar Technology’s lead engineer on the project. “There are so many opportunities for innovation, optimization and integration. Combining novel design solutions with innovative manufacturing processes means we can package hydrogen storage efficiently in a series of co-dependent chambers to form a storage bank, rather than fitting a number of standard independent cylinders into the space.”

“Hydrogen in a Box” offers significant flexibility in terms of geometry, opening new opportunities to efficiently store CGH2 in places where traditional cylinders would not be appropriate, such as in the wings of an aircraft or under the cabin floor and possibly even as part of the structure itself.

Polar Technology’s solution minimizes the amount of empty or lost space surrounding traditional cylinders, as well as enabling the capacity to easily increase volume when required by adding more tank sections. Furthermore, “Hydrogen in a Box” has the capacity to integrate valves and control systems within the design, removing the need for extra manifolds yet it doesn’t require the use of a chassis to hold separate vessels together, unlike other conformable or chained tank products on the market.

“Enabling technologies for a sustainable and healthier future is rooted in our vision and ethos as an organization,” says Daniel Chilcott, business development director for Polar Technology Management Group. “Polar Technology’s solutions, such as ‘Hydrogen in a Box,’ can provide our customers significant overall system improvements and enable real advancement in hydrogen propulsion as well as CO2 reduction.”

For more details contact: george.brown@polartechnology.co.uk

Related Content

JEC World 2023 highlights: Recyclable resins, renewable energy solutions, award-winning automotive

CW technical editor Hannah Mason recaps some of the technology on display at JEC World, including natural, bio-based or recyclable materials solutions, innovative automotive and renewable energy components and more.

Read MoreCollins Aerospace to lead COCOLIH2T project

Project for thermoplastic composite liquid hydrogen tanks aims for two demonstrators and TRL 4 by 2025.

Read MoreComposites end markets: Pressure vessels (2024)

The market for pressure vessels used to store zero-emission fuels is rapidly growing, with ongoing developments and commercialization of Type 3, 4 and 5 tanks.

Read MoreECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

Read MoreRead Next

Polar Technology, Moog Controls to develop H2 storage solution

“Hydrogen in a Box,” is an integrated hydrogen storage and management solution that will enable efficient packaging of Type III and Type IV vessels.

Read MoreUltima Forma, Polar Technology explore electroformed coating for aerocomposites

Electro-deposited erosion protection layer will be applied to aerofoil-shaped composite components to offer improvements to future technologies such as propeller blades used in eVTOLs.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More