IBEX 2013 preview

Louisville gets the nod for the fourth year in 2013, but in 2014 IBEX returns to Florida by popular demand.

As International BoatBuilders’ Exhibition and Conference (IBEX) officials prepared to set sail for the show’s fourth consecutive voyage to the Kentucky Exposition Center, Sept. 17-19 in Louisville, Ky., the winds of change were already blowing. Although IBEX cosponsors Professional BoatBuilder magazine and the National Marine Manufacturers Assn. (NMMA, Chicago, Ill.) indicated in 2012 that this inland destination on the Ohio River would be its boatbuilding show venue for the foreseeable future, IBEX officials announced on May 16 that, after further consideration, they have adopted a rotating show schedule to accommodate attendees and exhibitors elsewhere in the U.S. and those who come in from Latin America and the rest of the world.

Alternating schedule

“Louisville continues to be an excellent location for IBEX, but there are two major geographic areas in the USA where about 80 percent of boatbuilders in North America reside,” says Anne Dunbar, IBEX show director. “Rotating between these two cities is ideal for our dedicated IBEX attendees, and for all those marine professionals who have been unable to attend.” The 2013 event will take place in Louisville, but for 2014 IBEX will return to Florida, putting in at the port of Tampa. The IBEX 2014 show will be held Sept. 30-Oct. 2 at the Tampa Convention Center, a world-class event space. The facility is located on the waterfront and is within walking distance of many hotels, fine restaurants and attractions. Steps away from the show site, an expansive marina offers plentiful docks and slips. And dock space will be available to exhibitors on a first-come, first-served basis. (Exhibitors may reserve dock or in-water exhibit space at IBEX 2014. Contact Tina Sanderson, tina@ibexshow.com, or Kate Holden, kate@ibexshow.com.) The rotating schedule, based on a Tuesday through Thursday run, is already in place through 2019 (see the “IBEX: Louisville/Tampa Rotation,” last photo).

In Louisville for 2013, IBEX has asked Rick Pitino, coach of the University of Louisville men’s basketball team, to deliver the keynote address at the IBEX Industry Breakfast on Tuesday, Sept. 17, from 7:30 to 9:30 a.m.

dAs the Louisville Cardinals head coach since 2001, Pitino (pictured in secon photo) took his team to victory this year in the NCAA Men’s Division I Basketball Championship. He is the only NCAA coach to have led three different teams to the Final Four. Pitino’s keynote “is a great way to kick off IBEX,” says Dunbar. “We are confident everyone will enjoy his talk and take away some positive reflections they can apply to their own businesses.”

Prior to Pitino’s introduction, Thom Dammrich, president of NMMA, will deliver an opening address on the state of the marine industry and the opportunities available to boatbuilders in the coming years.

Down to business early

Although the exhibition opens on Sept. 17, the IBEX conference offerings begin a day early with Pre-Conference Workshops. This year, five hands-on presentations on Monday, Sept. 16, will cover the many uses of and techniques for using shrink wrap, and will survey composite infusion technology and composite boat design, with an introduction to composites and a primer on fiberglass boat repair.

IBEX has scheduled 75 seminars for the 2013 show under the thematic banner “Designed to Build Better Boats.” Highlights of interest to boatbuilders who work with composites will include “Prepreg Best Practices,” which aids boat shops that want to take advantage of recently developed out-of-autoclave prepreg technology to avoid issues such as bridging and racetracking that are common to vacuum infusion processes.

“Gel Coat Fundamentals” will review tips, tricks and best practices for the selection, storage, preparation and application of the component that makes up 5 percent of the composite structure but has historically been the source of 90 percent of composite boatbuilders’ challenges.

“Adapting Open Molds for Infusion” will deal with ways and means to do exactly that, including how to achieve desired results in both room-temperature cure and heat-cured vacuum infusion processes and how to avoid transition pitfalls.

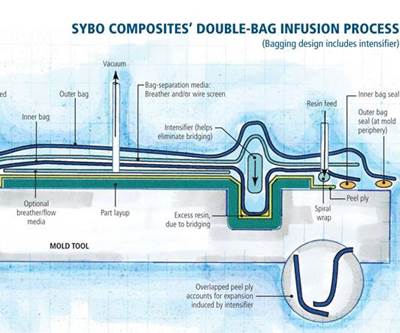

A “Double-Bagging Debate Update” will give attendees data from a second round of ongoing testing to determine the merits (or lack of same) of the double-bagging alternative to conventional single-bag infusion (to review evidence on both sides of the debate, see the titles under "Editor's Picks," at top right). “Bonding to Infused Laminates” will update attendees on the latest secondary bonding techniques and tabbing procedures. Other speakers will describe “Common Errors in Fiberglass Repairs” and how to avoid them, as well as “Best Practices in Open Molding.” They’ll take attendees “Inside the Bag: Vacuum Pressure Analysis” and help them “Stop the Creep: Transom Problems and Solutions.” They’ll describe how to avoid “Common Composites Processing Errors,” talk about the latest techniques for “Infusing Stringers and Floors,” and explain the benefits of one-off custom building by means of “Cold Molded Construction,” which combines wood and plywood with composite materials in a relatively simple process with low setup and tooling cost.

In addition, seven Exhibitor Workshops will help boatbuilders with topics that range from software-based yacht design and analysis and the surface quality of infused parts, to marketing boats and boat-related services and avoiding problems associated with inadequate knowledge of boat- and yachtbuilding standards.

On Tuesday, Sept. 17, IBEX will sponsor its fourth Opening Night Fourth St. LIVE! Networking Event. IBEX badge holders will be invited to enjoy music, drink and dinner specials in most downtown Louisville restaurants.

To see a complete schedule of events visit http://www.ibexshow.com/schedule_events.php. To register for the show, visit http://www.ibexshow.com/attendee-registration.php.

Related Content

European boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreMel Composites infusion strategy enables Sasga Yachts fiberglass hull designs

Mel’s ongoing partnership culminates in the development of the Menorquín 42 and Menorquín 54 motor yachts, as well as extension of Sasga’s capacity for 68-foot-length boats.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreRead Next

Double-bag infusion: 70% fiber volume?

A double vacuum-bag system and tight process control enable repeatable fiber volumes of 60 to 70 percent and improves consistency of infused laminates.

Read MoreSingle bagging can do the job

Mechnical engineer Peter Schwarzel (CarbonWorks, Coombabah, Queensland, Australia) comments on the “Engineering Insights” article in the CT December 2010 issue, titled “Double-bag infusion: 70 percent fiber volume?”

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More