Carbon fiber elevator rope rides to the rescue high in the sky

Steel rope was once the material of choice for elevator function, but as buildings exceed 500m in height, it's just too heavy. Elevator manufacturer KONE is offering pultruded carbon fiber rope, called UltraRope, for elevators in the world's tallest buildings.

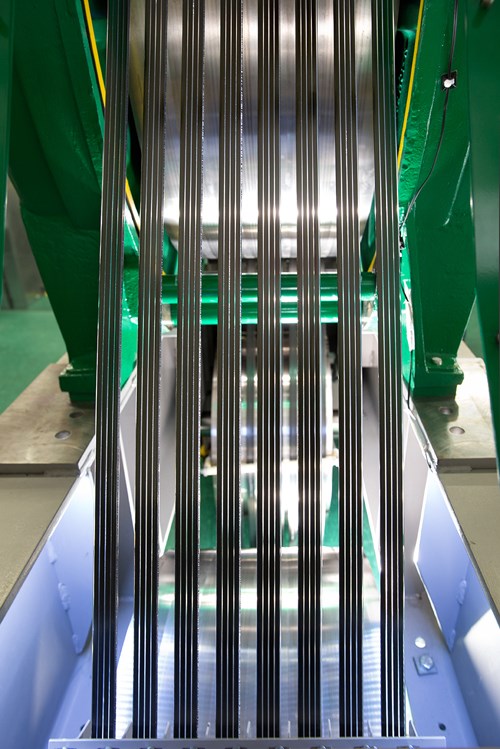

Pultruded carbon fiber KONE UltraRope installed in an elevator shaft.

Elevators are one of those everyday machines that are uncommonly easy to take for granted, but whose function depends on a myriad of material and devices that go largely unseen — and must function flawlessly.

One of those unseen devices is the system of steel rope that attach to and ride with an elevator. They have worked dependably for many years, but have one flaw that makes them unusable in the super-tall buildings that dominate urban landscapes: They are too heavy.

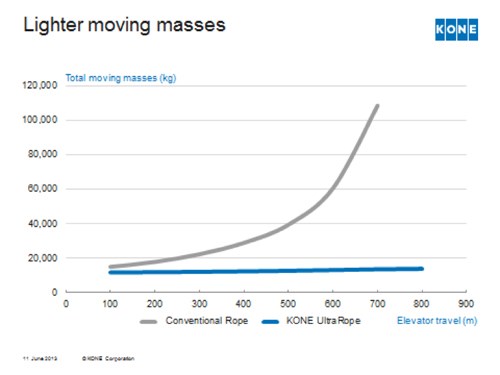

Indeed, says Simon Barrette, communications manager at elevator manufacturer KONE (Espoo, Finland), current steel rope technology has reached its height limit: elevator travel distances of more than 500m are not feasible as the weight of the ropes themselves becomes so large that more ropes are needed to carry the ropes themselves. In short: Rope weight increases exponentially with building height.

A few years ago, KONE's customers started asking if there was a way to eliminate steel ropes in elevator design. This, says Barrette, "began our research into finding ways to reduce the weight of the ropes and we started looking at alternative materials. We benchmarked solutions from other industries and came across carbon fiber technology, which has already been used to reduce weight in industries such as aviation, automotive and the machine industry."

In 2013, KONE launched the KONE UltraRope, a belt-like rope fabricated via pultrusion with carbon fiber, with a polyurethane coating. Barrette says KONE UltraRope was patented in 2008 and research of the application properties including thorough testing was conducted for seven years. According to the KONE patent for UltraRope, the rope is wider than it is thick, features a series of V-shaped longitudinal grooves, and can be pultruded with epoxy, polyester, phenoic or vinyl ester resins. The rope was tested at KONE's Hyvinkää reliability lab and testing towers, as well as at the Tytyri high-rise testing facility. Focus areas have been lifetime, environmental effects, temperature behaviors and friction properties in applicable conditions.

Steel rope, as elevator travel increases, exponentially increases the total moving mass of the elevator. KONE UltraRope, made with pultruded carbon fiber, dramatically reduces moving mass.

The result? KONE UltraRope will reduce the total cost of ownership thanks to significant reduction of energy consumption, reduction of downtime caused by building sway and the longer lifetime (2X) of ropes themselves, compared to steel. For an elevator with a travel height of 500m, energy savings would be approximately 30%. For an elevator with a travel height of 800m, energy savings would be as much as 45%.

Carbon fiber also offers an ancillary benefit as well, says Barrette. "In strong winds buildings start to sway, which also causes ropes to sway," he says. "At certain elevator positions rope resonance cannot be totally eliminated and for safety reasons elevator speed needs to be reduced or the elevators need to be completely stopped. KONE UltraRope resonates at a higher frequency than steel and most other building materials, meaning it is less likely to start resonating in high winds and this problem is minimized. Typically, building sway for very tall buildings is measured in tens of centimeters; in extreme cases, the sway can be more."

The first elevator hoisted with KONE UltraRope was installed in one of Marina Bay Sands resort’s elevators in Singapore in September 2013. The Kingdom Tower Jeddah (Jeddah, Saudi Arabia), the world’s future tallest building (1 km high) once completed at the end of 2018, will feature KONE UltraRope technology and the fastest and longest DoubleDeck elevators in the world.

Kingdom Tower Jeddah, in Jeddah, Saudi Arabia, when completed in 2019, will be the tallest building in the world at 1 km (1,000m). For comparison, the Freedom Tower in New York City is less than half that height at 417m.

Related Content

CirculinQ: Glass fiber, recycled plastic turn paving into climate solutions

Durable, modular paving system from recycled composite filters, collects, infiltrates stormwater to reduce flooding and recharge local aquifers.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreComposites end markets: Electronics (2024)

Increasingly, prototype and production-ready smart devices featuring thermoplastic composite cases and other components provide lightweight, optimized sustainable alternatives to metal.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)