Increased competition from metals

Boeing and Airbus are developing new, lightweight, corrosion-resistant metals that are targeting composites' traditional niche in the material sphere.

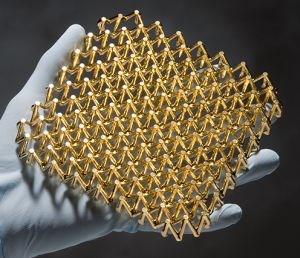

High-strength, lightweight metal lattice materials are being developed by Boeing. SOURCE: Architected Materials.

So this involves three stories which were all on the Engineering Materials website, and which presented an interesting snapshot of where metals are headed — namely, right where composites have been (corrosion-resistant, lightweight, interiors) and where they fight to increase penetration (landing gear, metal structures).

- Airbus' development of a new corrosion-resistant stainless steel alloy, “CRES”, for aircraft landing gear;

- Harvard SEAS' portfolio of slippery anti-corrosion coatings that also boost steel's strength;

- The backstory on Boeing's pursuit of the lighter-than-air metal microlattice (vs. polymer), aimed at applications including aircraft interiors.

Airbus is developing a new CRES corrosion-resistant stainless steel alloy for landing gear components, like this forged piece cooling on a palette. SOURCE: Airbus

Intrinsic corrosion resistance without coatings

Airbus is developing the new corrosion-resistant stainless steel alloy (CRES) in partnership with landing gear manufacturer Messier-Bugatti-Dowty (Vélizy-Villacoublay, France), steel and titanium alloy producer Carpenter Technology (Wyomissing, PA) and the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Rotherham, UK). According to Airbus, CRES eliminates the need to use traditional cadmium and chromate coatings and imparts intrinsic corrosion resistance to the metal. With strength comparable to current steels, cost possibly half that of titanium alloys and potential to reduce cost of ownership due to improved corrosion resistance, fracture toughness and stress cracking, it is being targeted to replace both steel and titanium alloys for future aircraft landing gear. Composites have made significant inroads in metal replacement thanks to these same qualities.

Nine A320 main landing gear components have been forged from CRES and are being used to further develop the material, including establishing as-manufactured properties and optimizing the route to industrialization. Two components have been manufactured to a final finish, and the team hopes to assemble a fully CRES landing gear for in-service evaluation.

Steel is prone to corrosion from water, salt, abrasion and organisms (left) but new slippery coatings made from electrodeposited tungsten-oxide (TO) islands can resist even accelerated corrosion exposure to very corrosive Glyceregia etchant (right). Unmodified stainless steel has corroded (right sample) but the lower part of the left sample holds up well thanks to its 600-nm thick TO film coating. SOURCE: seas.harvard.edu and Wikicommons (left) and materialsforengineering.co.uk (right).

Improved anti-corrosion coatings

This more traditional avenue for mitigating the corrosion weakness of steel and other metals is also getting some uber performance technology. Researchers at Harvard University's John A. Paulson School of Engineering and Applied Sciences (SEAS, Cambridge, MA, US) have developed a nanoporous tungsten oxide coating that reportedly repels any kind of liquid, even after sustaining intense structural abuse. SEAS researchers noted that while steel alloys have developed, steel surfaces have remained largely unchanged, still prone to the corrosive effects of water, salt and abrasive materials such as sand. Led by Professor Joanna Aizenberg, the SEAS team developed Slippery Liquid-Infused Porous Surfaces (SLIPS) in 2011, and now claim "slippery steel" that is orders of magnitude more durable than any anti-corrosive coating developed before.

The key is surface engineering that enables the design of materials which can perform multiple, even conflicting, functions, without degradation of its inherent performance. Electrochemical deposition — already widely utilized in steel manufacturing — is used to grow an ultrathin film of hundreds of thousands of small and rough tungsten-oxide islands directly onto a steel surface. These islands not only provide an anti-wetting surface which repels liquids, they also make the steel stronger.

The coated steels are being aimed at applications like medical tools and devices (e.g., implants and scalpels), nozzles for 3D printing and possibly even buildings and marine vessels.

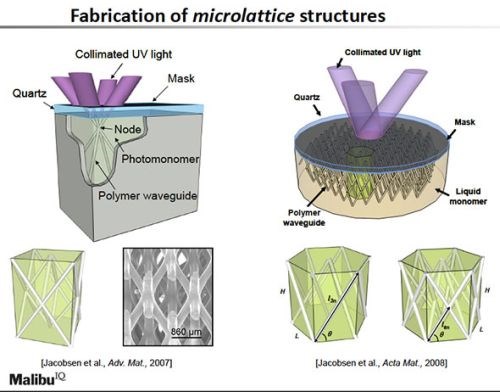

Though many publications are just recently announcing this development, it actually began almost a decade ago. CW reported on it in 2011. The interesting thing is that it started out as a polymer-based system. Rachel Park wrote a great article, "Materialising Micro Lattice Structures" in 2013, which explains the technology really well. The beginnings of all microlattice structures are resin photomonomers and UV light.

Collimated UV light is directed into photomonomer resin through a mask with thousands of small holes, and a layer of quartz, to form self-propagating photopolymer waveguides, that in turn form micro lattice structures. SOURCE: Rachel Park, 3dprintingindustry.com

So this development comes out of HRL Laboratories (Malibu, CA, US), which is jointly owned by Boeing (Chicago, IL, US) and General Motors (Detroit, MI, US). What's interesting to me is that Boeing is publicizing its development of the technology into the world's lightest metal and its potential to replace current materials in applications like aircraft interiors.

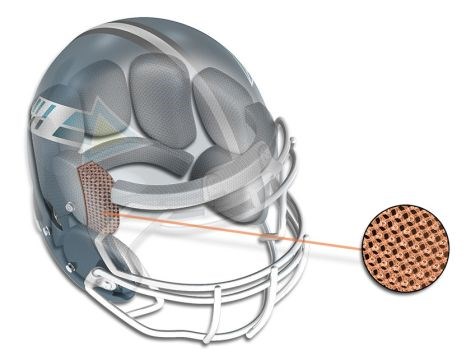

Architected Lattice is commercializing microlattice materials into a variety of applications, including football helmets. SOURCE: Architected Lattice.

Meanwhile, Architected Materials (Ventura, CA, US), which was established in 2011 to commercialize this Architected Lattice material beyond aerospace and automotive, has announced its win of a grant sponsored by the National Football League, General Electric and Under Armour, to develop microlattice plastics as a replacement for foam in football helmets. The materials will absorb impact energy, limit peak loads and reportedly can be enhanced with a strain-sensing “smart lattice” to detect and transmit impact data which could further improve helmet design and performance. They also permit more air flow, and thus, are more breathable than current foam materials.

Architected Lattice sees a nearly endless potential for microlattice structures and does not appear to be tied to plastics, metals or any other materials. But back to our beginning, Boeing sees its largest play in microlattice metals. So, composites indeed have new competition, but there may also be new opportunity. The challenge will be figuring out the latter.

Related Content

The lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreREGENT progresses seaglider prototype development, prepares for crewed testing

All-electric composites-intensive maritime craft will enhance coastal transportation capabilities by mid-decade.

Read MorePro-Set named official materials supplier for New York Yacht Club American Magic

Competitive sailing team prepares for the 37th America’s Cup beginning in August 2024 with adhesives, resins and laminate testing services for its AC75 monohull construction.

Read MoreNlcomp launches recyclable composite sailing boat Ecoracer30

Italian startup featured its 30-foot sustainable production boat at the Ocean Race Grand Finale in Genoa, Italy, citing the challenges, highlights and future related to its development.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More