Infusion enthusiasm

Although CW didn't attend the EAA AirVenture in Oshkosh in 2015, we did learn about an infusion demo that was the largest ever accomplished at the fly-in event.

A three-day infusion demonstration at Oshkosh in July attracted hundreds who learned from a team of composites experts.

CW didn’t attend the EAA AirVenture air show in Oshkosh, WI, US this year (http://www.compositesworld.com/articles/general-aviation-heats-up-at-oshkosh). Which was too bad – because we missed a well-attended demonstration of a one-shot infusion of an entire aircraft fuselage, the largest infusion project ever completed at the Oshkosh show. Russ Emanis, a well-known industry consultant who is currently chief composite engineer at Innegra Technologies (Greenville, SC, US) led a team that successfully fabricated the two large fuselage halves, and Innegra Technologies sponsored the entire three-day demo. We’ve covered his infusion technology; here are a couple of links to previous stories: http://www.compositesworld.com/articles/double-bag-infusion-70-fiber-volume; http://www.compositesworld.com/articles/the-evolution-of-infusion.

First, a little background. Emanis has conducted tutorials and demos on composite materials and processing at many past AirVenture events, because the Experimental Aircraft Assn. includes many flying enthusiasts who build their own planes with composite materials. Tony Pileggi, head of the EAA member program for replica fighters and the Replica Fighters Assn., approached Emanis this year with a plan: conduct a demonstration on infusion, using the molds for Pileggi’s own 82% scale F4U Corsair fuselage. The demo would teach valuable composite fabrication techniques, and result in useable parts to help complete his group’s scale model of the renowned WWII-era fighter (see link to Pileggi’s Corsair page: http://www.corsair82.com/index.html). Why 82%? Pileggi says it’s because the engine he found for the replica has a diameter 82% of the size of the original Corsair’s powerplant. Emanis adds that the fuselage halves are not intended as monocoque airframe structure but rather as skins that will be attached to a tubular steel frame, to form the aircraft’s shape.

Emanis brought together a team that included representatives of Scott Bader Co. Ltd. (Northamptonshire, UK) for resin, TeXtreme (Boras, Sweden and Chicago, IL, US), Innegra, Sigmatex (Benicia, CA, US) and Saati Americas Corp. (Fountain Inn, SC, US) for reinforcements, and German Advanced Composites (Miami, FL, US) for MTI infusion tubing and ancillaries. Emanis explains that the 7m-long molds supplied by Pileggi were splash molds pulled from patterns, and originally intended for wet layup, and presented some hurdles: “It was a challenge to make this work. There was some leakage in the molds but we managed to overcome the issues.”

Fuselage molds were cleaned and sealed prior to layup.

Held under a large tent, the demo began with the team first cleaning the molds and applying mold sealer and release. Using a material rack built on site, layup commenced with the first of three plies of the donated materials: a hybrid TeXtreme spread carbon/Innegra woven fabric. This was followed by a Sigmatex ±45° biaxial carbon fabric, then a 2x2 “scoured” carbon twill (without sizing) provided by Saati as the third ply. Day Two involved completion of the final layup, prep for infusion and application of bagging materials, with explanations provided to the crowd (which numbered in the hundreds at times) with each step. Finally, the third day involved the actual infusion of the two parts.

Reinforcements for the fuselage halves included TeXtreme carbon/Innegra fabrics and a biaxial provided by Sigmatex.

Jeff Starcher, Scott Bader’s representative at the event, says that the Crestapol 1250 urethane acrylate resin was a great choice for the demo, because of its low viscosity, high toughness, the fact that it bonds well both to carbon and Innegra polypropylene fibers, and its ability to achieve cure at ambient temperature. With no autoclave or oven, the resin was left to cure in the sun at ambient temperature, about 28°C, which Starcher says is a “good temperature” for the resin system. Emanis adds that the resin was promoted to provide a pot life of about 60 minutes: “Crestapol is a phenomenal resin, since you can really control the flow with its low viscosity. We were able to eliminate pinholes, and had plenty of time to fully infuse the parts.” Infusion of each mold was accomplished in about 25 minutes, using 3 feed lines per mold. One vacuum leak was identified during the infusion, he adds, which caused a dry spot, but “we were able to insert a vacuum needle in there and draw resin in, to eliminate the problem.”

Scott Bader Crestapol 1250 resin was used for the infusion.

The infusion team with one of the completed fuselage halves. The parts are destined for a reproduction of an F4U Corsair fighter jet.

The demo was, according to the team participants, a resounding success. Says Emanis, “This was really fun and cool. The idea was to train and talk to people and let them understand the infusion process. We had lots of folks say to us ‘wow- you made this make sense’.” He adds that plans are in place to continue work with Pileggi on additional Corsair parts, including the wings, bulkheads and more, within a few months. Emanis has filmed much of the Oshkosh demo and will continue to film as the Corsair aircraft project progresses.

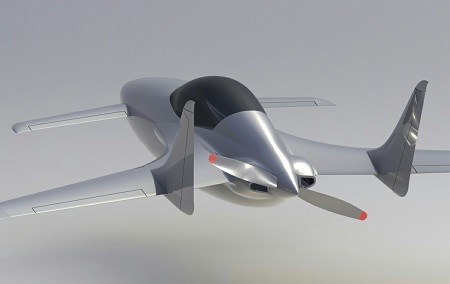

Next year's infusion project will produce parts for this new aircraft designed by Jeff Kerlo

And, stay tuned for AirVenture 2016. Because the team approach worked so well, says Emanis, he’s going to again tackle an infusion demo of a new composite aircraft designed by Jeff Kerlo (V-Raptor Aircraft LLC, Atlanta, GA, US) who is Emanis’ partner in this new aircraft project . The plane’s production tooling will be at Oshkosh and parts will be infused during a demo, using carbon/Innegra reinforcements over core. Innegra will again sponsor the demo event, and more information is available from Jen Hanna at Innegra. CW will definitely be keeping tabs on this new design, and the increasing enthusiasm for aircraft infusion.

Related Content

Manufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MorePultrusion: The basics

A primer describing what pultrusion is, its advantages and disadvantages, and typical applications.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More