Interplay Of Materials And Use Conditions Key To Design

A wide variety of thermoplastic resins is used for the inner fluid/pressure barrier layer, which contains the conveyed material and eliminates any possibility of weeping through the fiber composite. The most common are families of polyolefins (e.g., polyethylenes), polyphenylene sulfides (PPS), nylons (polyami

A wide variety of thermoplastic resins is used for the inner fluid/pressure barrier layer, which contains the conveyed material and eliminates any possibility of weeping through the fiber composite. The most common are families of polyolefins (e.g., polyethylenes), polyphenylene sulfides (PPS), nylons (polyamides) and fluorinated polymers such as polyvinylidene fluoride (PVDF) for higher-temperature or more aggressive chemical uses. Fiberspar’s Quigley says, “The range of chemicals that one can encounter in the production of oil and gas covers a tremendous spectrum, from concentrated sulfuric acid to drilling mud with high pH. So the selection of the liner material is obviously very dependent on the chemicals present in the specific application.” The liner’s mechanical properties are also important. Impact strength, fracture toughness, crack growth fatigue resistance and tensile strength must be considered, based on the intended service conditions.

High-density polyethylene (HDPE) is the least expensive liner material. Though resistant to most chemicals seen in typical flowline applications, it is generally limited to use temperatures below 140°F/60°C. Rilsan, a polyamide 11 nylon made by Atofina Chemicals Inc. (Philadelphia, Pa., U.S.A.), has been used as liner material in offshore flexible pipe for over 25 years, based on its corrosion resistance and temperature performance (to about 195°F/90°C). Several oil field operators participate in a Rilsan User’s Group that monitors the long-term performance of this material. PVDF is generally selected for the highest temperature applications (up to 265°F/130°C) and in some instances, polyetheretherketone (PEEK) has been selected, where very high temperature performance and toughness were required.

Research into new polymer candidates for liner material continues at a significant level, says Dr. Robert Campion of the Materials Engineering Research Laboratory Ltd. (MERL, Hertford, U.K.), who has investigated the properties of several perfluoroplastics (PFA and MFA) for high-temperature flexible pipe service. An American Petroleum Institute (API) technical document on high-temperature polymers for thermoplastic liners is in preparation.

Carbon fiber suppliers like Tenax Fibers (Wuppertal, Germany) and Grafil Inc. (Irvine, Calif., U.S.A.) are involved in extensive testing of their products for offshore uses, including spoolable tubulars. Tenax’s STS 5631 24K fiber has undergone tensile and fatigue strength evaluation, among other tests, at the Norwegian University of Science and Technology (NTNU) in Trondheim, related to potential deep water applications. Tenax is also working on a new fiber for combining with thermoplastic resins, for the downhole sector.

A variety of end connections is available for different requirements. Essentially, any connector that is employed on a steel pipe can be integrated into a spoolable product, including those for threaded joints, as well as API and American National Standard Institute (ANSI) fixed and swivel flanges, and hub type and welded connectors. Tubing for a workover requires a flush-outer-diameter end connection, while a lap-joint-type connector is compatible with the standard raised face flanges used on most line pipe.

It is important that the connection design includes a stiffness transition feature that limits any stress concentration on the composite. Qualification of a spoolable composite product should always include qualification of the particular end connector design that will be employed in the application.

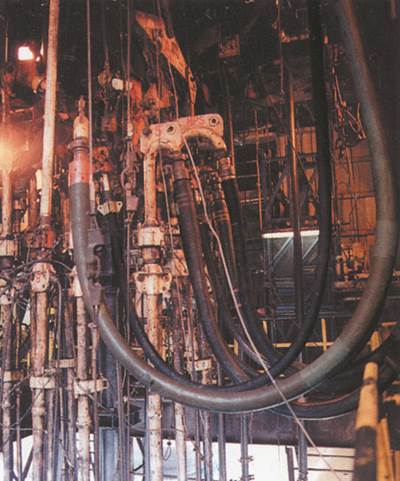

“The development of a bend restrictor or stiffener is necessary for subsea installation of a spoolable composite pipe,” says Bjørn Melve of Statoil’s research center in Trondheim, Norway, referring to the installation of a 21,125 ft/6,500m length of spoolable glass/epoxy methanol injection line in the North Sea Åsgard field during 1999.

To prevent damage to composite piping, handling risks must be considered. The loads and the interactions with equipment will differ from application to application. Therefore, the establishment of handling procedures and training programs should be given high priority.

Related Content

McLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Issues With Design

Though steel is the traditional material for coiled tubing because of its low price, it is susceptible to corrosion, fatigue failure (caused by repeated coiling and uncoiling), and troublesome joints. In larger sizes, its weight can increase transport difficulties. With the advent of secondary recovery methods

Read MoreSpoolable Composite Tubular Applications

Applications for spoolable composite tubulars can be divided into three major areas — onshore, offshore and downhole. Onshore applications, which include production and gathering lines that convey fluids between wells and surface facilities, are well-suited to spoolable composite tubing and RTP. Offshore appli

Read MoreRTP Niches Into Low-Pressure Applications

Wellstream (a Halliburton business unit) supplies lightweight reinforced thermoplastic pipe, or RTP, which is designed for applications intermediate between those that can use low-pressure, unreinforced thermoplastic pipe or hose, and those that require high-pressure unbonded flexible pipe. Used mainly in onsh

Read More

.jpg;maxWidth=300;quality=90)