Spoolable Composite Tubular Applications

Applications for spoolable composite tubulars can be divided into three major areas — onshore, offshore and downhole. Onshore applications, which include production and gathering lines that convey fluids between wells and surface facilities, are well-suited to spoolable composite tubing and RTP. Offshore appli

Applications for spoolable composite tubulars can be divided into three major areas — onshore, offshore and downhole. Onshore applications, which include production and gathering lines that convey fluids between wells and surface facilities, are well-suited to spoolable composite tubing and RTP. Offshore applications, such as subsea flowlines, dynamic production and export risers, jumpers and choke and kill lines, have traditionally been the domain of unbonded and bonded flexible pipe. Downhole applications for composite pipe are still developing, and include directional drilling, well intervention and completion tubulars. Spoolable composite tubing is the principal product being marketed for these applications.

More than 1 million ft of Fiberspar’s 2 inch to 4 inch/50 mm to 100 mm diameter spoolable composite piping is installed and operating in North America, primarily as onshore flowlines. Fiberspar’s 3 inch/75 mm line pipe, while designed for 3,000 psi/210 bar long-term service, has been tested to burst pressures as high as 15,000 psi/1,000 bar. Considerable qualification testing has been performed, in accordance with API standard 15HR and American Society for Testing & Materials (ASTM) Standard D2996, regarding chemical and temperature compatibility, burst performance, collapse performance, dimensional change while pressurized, end connection performance and minimum bend radii.

Shallow offshore applications are growing, for new seabed flowlines or remediation of corroded steel lines. During 2000 and 2001, over 150,000 ft of Fiberspar composite line pipe was installed offshore in the Gulf of Mexico. For one operator in the Gulf, 2.25 inch/56 mm (ID) piping was pulled inside 80 existing steel pipelines, essentially creating new, corrosion-resistant flowlines at a reduced cost. An added benefit was that the composite piping installation had minimal environmental impact, compared to the lengthy process of removing and then re-burying replacement lines in the seabed.

The work was accomplished by pulling 2.5 inch/62.5 mm, 750 psi-rated spoolable tubular product through the buried 3 inch/75 mm steel flowlines, by pigging the steel lines with an attached wireline. The wire was then attached to the pipe with a specially designed pulling head and a wireline unit was used to pull the spoolable pipe inside the steel lines. The pipe was tied into the wellhead on one end and to spool piping on the other end with mechanical compression fittings. The lower surface friction factor of the composite pipe, as compared to the corroded steel, improved flow. Project cost was one-third that of conventional steel pipe replacement.

Fiberspar has also installed new shallow subsea production gathering lines and gas injection lines. The lines were jetted in and weighted with concrete to overcome the positive buoyancy of the airfilled composite piping.

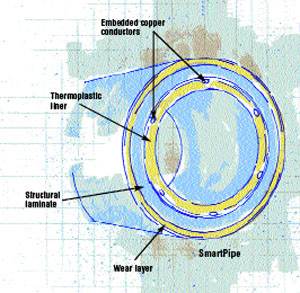

Perhaps the most exciting development for spoolable composite tubing is the Anaconda Advanced Well Construction System, jointly developed by Halliburton and Statoil with the goal of improving directional, extended-reach drilling in the Norwegian sector of the North Sea. The first phase of Anaconda, termed System I, is based on a 3.12 inch/78 mm spoolable SmartPipe carbon fiber composite pipe, developed and manufactured by Fiberspar. Copper conductors, embedded within the composite laminate, allow real-time power and data transmission. The conductors facilitate control of drilling operations and collection of accurate depth measurements without the need for expensive batteries, downhole turbines or slow simplex mud pulse telemetry. As the systems evolve through use and further refinement, Fiberspar will manufacture larger versions of SmartPipe, in diameters of 4.25 inches/ 106 mm and 5.5 inches/137.5 mm.

“One advantage of composite tubing in the system is its neutral buoyancy in drilling mud,” says Kalman. “You can pull it with a down-hole tractor as you drill, enabling extended-reach drilling. If you try that with steel coiled tubing, the friction — due to the weight — overcomes the pulling load.”

Anaconda System I was tested in two onshore Halliburton wells during 1999 and 2000, and the company is currently commercializing the drilling system. Fiberspar produced a 21,000 ft/6,462m length of SmartPipe in June 2000, which consumed more than 10,000 lbs of 12K carbon fiber tow supplied by Grafil, creating what might be the world’s largest carbon fiber part.

“The potential of spoolable composites in deep offshore applications is being realized today,” says Fiberspar’s Quigley. “And there is potential for new applications and market growth for many years to come.”

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

Issues With Design

Though steel is the traditional material for coiled tubing because of its low price, it is susceptible to corrosion, fatigue failure (caused by repeated coiling and uncoiling), and troublesome joints. In larger sizes, its weight can increase transport difficulties. With the advent of secondary recovery methods

Read MoreSpoolable Composite Tubulars

A new generation of spoolable piping offers fatigue resistance and lower life cycle costs.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More