Leichtbau ist hybridbau

Integrating multiple materials and functions for lightweight construction in the German automotive industry.

The Institute for Lightweight Hybrid Systems (ILH) at the University of Paderborn (Paderborn, Germany) is researching a broad range of technologies for future automotive structures using multiple materials. SOURCE: ILH

In researching a German automotive development project for an upcoming article, I discovered an article titled “Leichtbau ist Hybridbau”, i.e., “Light construction is hybrid construction.” Granted, my ability to correctly understand the text relying solely on Google Translate is dubious, but the gist I got was that instead of looking at either metals or plastics (composites are a subset, as fiber reinforced plastics), increasingly German designers are taking another tack: a hybrid structure using multiple materials.

This trend seems to have exploded over the past 3 to 4 years in Germany. Even Volkswagen, which has proudly touted cutting 23 kg/51 lb from the Golf VII using high-strength steel — not carbon fiber — has also formed the Open Hybrid LABfactory, as explained by Prof. Dr. Jürgen Leohold, Head of Volkswagen Group Research:

"For the large-scale light alone is not feasible with expensive lightweight materials. Rather an intelligent multi-material mix is required for success in the market, which enables new methods suitable for mass production. With our partners in the Open Hybrid LABfactory we are developing hybrid multi-material structural components, made of plastic, metal and high-performance fibers in a single production step."

This public-private project claims to include the entire value chain from carbon fiber to finished part, staffed with approximately 200 employees from more than 30 companies contributing technology expertise via shared, cooperative R&D in a new 7,000 m2/74,350 ft2 facility located near Wolfsburg, Germany (VW headquarters).

SOURCE: Open Hybrid LABfactory website.

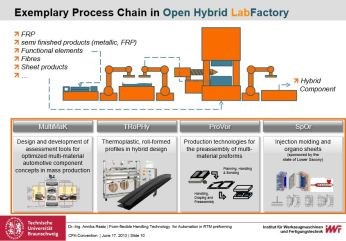

The Open Hybrid LABfactory website announces its first three research programs:

- ProVor - Functional Integrated Process technology for prefabrication of FRP-metal hybrids — Research and implementation of a production technology for pre-assembly of load-adapted FRP-metal preforms for the technical press processing.

- Trophy - Thermoplastic, roll formed sections in hybrid construction (BMBF) — Development of a continuous process for the production of profiles with variable cross-sections and bends in fiber-composite-metal hybrid materials with a thermoplastic matrix for new vehicle concepts.

- MultiMaK - development of design and assessment tools for use meet ecologically optimized multi-material automotive component concepts in mass — Development of methods and tools for analysis and comprehensive evaluation (economic, ecological, technical) product and process chains for the use of multi-material lightweight-based materials in high volume.

Open Hybrid LABfactory objectives and partners. SOURCE: ILH

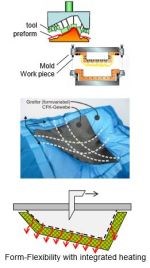

The slide above showing the lab’s many partners is from a presentation labeled “Form-flexible Handling Technology for Automation in RTM preforming” (CFK Convention on June 17, 2013) given by Dr.-Ing. Annika Raatz, leader of the Assembly and Production Automation Research Group at the Technische Universität Braunschweig. She describes joint research between the Institute of Machine Tools and Production Technology (Institut für Werkzeugmaschinen und Fertigungstechnik, IWF) and the Institute of Joining and Welding (ifs), also at TU Braunschweig, to developed automated preforming for resin transfer molding (RTM) which integrates the functions of handling, draping and bonding into one machine system.

Dr. Annika Raatz describes research at the Institute of Machine Tools and Production Technology (IWF) automating RTM preform operations via FormHand, a new tool which uses a form-flexible gripper with integrated heating. SOURCE: “Form-flexible Handling Technology for Automation in RTM preforming” by Dr. Annika Raatz, TU Braunschweig.

David Vink, the author of “Leichtbau ist Hybridbau”, says that the Open Hybrid LABfactory facility will be operational in 2015 and that TU Brunschweig is working on hybrid hoods that are 30 percent lighter than steel, using 0.2mm/.008 inch thin steel plate as a jacket around a carbon fiber reinforced plastic (CFRP) core.

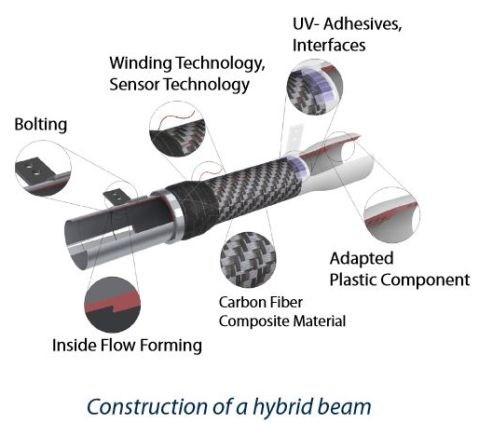

Vink goes on to describe two more hybrid lightweighting projects in Germany. The first is led by the Institute for Lightweight Hybrid Systems (ILH), established in 2012 at the University of Paderborn. ILH is working to develop metal structures reinforced with CFRP that do not require “glue, rivets or screws.” A carbon fiber/epoxy prepreg is stamped along with sheet metal at 0.2 to 0.5 N/mm pressure in a die preheated to 180°C/356°F, the epoxy curing in 2 minutes. A post-cure of 30 minutes in a 180°C oven occurs simultaneously with hardening of the CDL powder coating on the metal sheet. ILH has developed shaped sandwich structures comprising a base steel sheet, a carbon fiber composite core and a cover sheet of aluminum or steel. It claims weight is reduced by 35 percent vs. pure steel with one-quarter to one-fifth the thickness yet same strength and crash behavior. The project is reportedly supported by Benteler-SGL (Ried im Innkreiss, Austria), Johann Meier tooling and Audi (Ingolstadt, Bavaria, Germany). Vink notes that the Benteler’s local Paderborn facility has already developed a metal B-pillar with local CFRP reinforcements. Its goal is 150,000 pillars, sills or roof frames per year with a 96-sec cycle time.

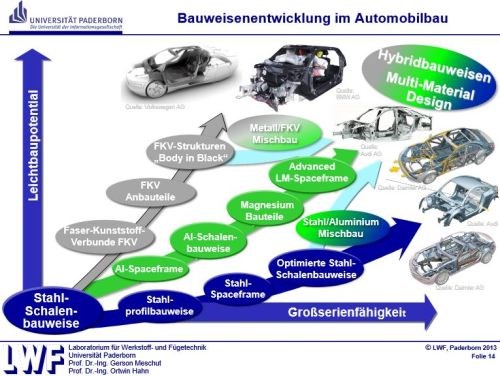

Potential for lightweight (y-axis) vs. large-scale production capacity (x-axis) of FRP (gray), aluminum (green) and steel (blue) materials in automotive structures.

SOURCE: University of Paderborn, ILH

Vink also describes work by the Institute for Lightweight Structures and Polymer Technology (ILK) of the Technical University Dresden AG (TUDAG). ILK was a participant in the BMBF (German Ministry of Education and Research) funded InEco project with partners including steel producer ThyssenKrupp (Essen, Germany), plastics supplier Evonik (Essen, Germany) and lightweight research center Saxony LZS. The resulting affordable and sustainable urban electric vehicle InEco was presented at the 2013 Frankfurt Motor Show and Composites Europe (Sep 17-19) and K Show plastics (Oct 16-23) trade fairs, both in Düsseldorf. It used a multi-material design to achieve significant parts integration, reducing components by 70 percent vs. conventional designs. During this project ThyssenKrupp established its TechCenter Carbon Composites and its Carbon Components business unit, the latter producing CFRP wheels which are 30 to 50 percent lighter vs. standard alloy versions.

The Audi R8 e-Tron combines an aluminum front section with a

multi-material space frame which also contains CFRP.

SOURCE: Audi, David Vink article “Leichtbau ist Hybridbau”

As a demonstration actually nearing commercialization, Vink puts forth the Audi R8 e-Tron, which he says will have an aluminum front body but a Multi-material Space Frame (MSF) for ultra-lightweight. The high-voltage battery unit includes both aluminum and CFRP and is load-bearing along with the CFRP luggage compartment tray described as “wavy” (see above image). Vink says Audi refers to the outer skin as “almost” made of CFRP but the passenger compartment and front cover (hood?) are very much CFRP, the latter reportedly having up to seven layers of carbon fiber mats. Vink says Audi plans to bring the R8 e-Tron to market this year.

There are two new hybrid lightweight construction projects at Karlsruhe Institute of Technology (KIT): “HyPro” and “KraSchwing”. These are funded by the German state of Baden-Württemberg as part of its extensive strategy to promote lightweight construction in its region.

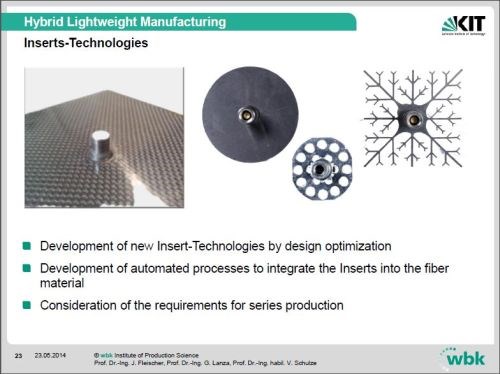

HyPro is developing technology for economically efficient production of hybrid metal, plastic and composite automotive structures using RTM and is coordinated by KIT’s Institute of Production Science. Partners include Fraunhofer Institute for Chemical Technology (ICT) in Pfinztal near Karlsruhe and six industrial companies. Researchers are studying RTM process steps – layout, pre-forming, infiltration, and post-processing – with a focus on pre-forming of continuous fiber textile semi-finished products in combination with metallic elements. The head of the HyPro project Professor Jürgen Fleischer explains, “Draping, positioning, and fixing of the fiber mats during pre-forming result in the basic structure of the component.” KIT reports that another focus is tool technologies for resin impregnation of the preforms and sealing of the mold. The results will be validated using a demonstrator constructed by project partner Porsche AG (Stuttgart, Germany).

The second project, KraSchwing, pursues optimizing technology for joining fiber-reinforced and metallic hybrid lightweight components, specifically aiming to improve the stability of both bonded and innovatively screwed structures under dynamic loading. Partners include the German Aerospace Center (DLR) in Stuttgart, the KIT Institute of Vehicle System Technology (FAST), and the Institute for Natural Sciences and Medicine (NMI) in Reutlingen, with six other enterprises.

Karlsruhe Institute of Technology (KIT) is pursuing a wide range of hybrid lightweight construction research, including enabling fastener technologies. SOURCE: KIT.

In total, the Baden-Württemberg state government is funding five joint research projects on hybrid lightweight construction worth roughly EUR 1.63 million. “The funded projects contribute decisively to the automation of production processes or the joining of hybrid lightweight components. Enhanced cooperation of science and industry in innovation partnerships paves the way towards a rapid transfer of viable lightweight construction technologies from research to the industrial production of marketable products,” says the Minister of Science Theresia Bauer.

KITe HyLITE, another of the state-funded hybrid lightweighting projects is directed by the Institute for Automotive Systems Engineering and Institute of Lightweight Technology in Karlsurhe and pursues combining long fiber thermoplastics (LFT), metals and continuous fiber reinforced plastics along specific technology corridors.

- Project A — LFT Hybrids

- Project B — Multi-PUR

- Project C — Inno-RTM

- Project D — In-Situ Comp

- Project E — Fiber Handling

Fraunhofer also participates in the project.

MERGE is yet another lightweight structures research organization, this one emphasizing the integration of multiple functions. It aims to merge technologies for mass-production, comprising plastic, metal, textile and what it terms “Smart Systems” into resource-efficient processes and products. Over 100 researchers from six interacting “research domains” are participating, with EUR 31 million in funding from 2012 to 2017.

And to bring it round full-circle, whereas the Open Hybrid LABfactory is supported by the German state of Lower Saxony, Baden-Württemberg has its own: Active Research Environment for the Next generation of Automobiles, or ARENA2036. Launched on June 3, the flexible research ARENA2036 factory for the car of the future — 2036 is the automobile’s 150th anniversary — is dedicated to realizing new, resource-efficient and competitive production models. Its website explains that lightweight automotive components in the future are not only based on fiber-reinforced plastics but also metals. Weight and cost savings will be achieved by integrating not only materials during manufacture, but also multifunctional properties such as sound and thermal insulation as well as sensory and electrical systems. Currently, there are four main projects:

- LeiFu — Intelligent lightweight with functional integration

- DigitPro — Digital prototype: new materials and processes

- ForschFab — Research Factory: production of future

- Khoch3 — Creativity, cooperation, competence transfer

Though one of the presentations and the video below are in German, they give a good idea as to the future of automotive composites where Leichtbau ist Hybridbau.

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreNovel composite technology replaces welded joints in tubular structures

The Tree Composites TC-joint replaces traditional welding in jacket foundations for offshore wind turbine generator applications, advancing the world’s quest for fast, sustainable energy deployment.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)