Leonardo and CETMA: disrupting composites for lower cost and environmental impact

Italian OEM and tier supplier Leonardo works with CETMA R&D to develop new composite materials, machines and processes, including induction welding for in-situ consolidation of thermoplastic composites.

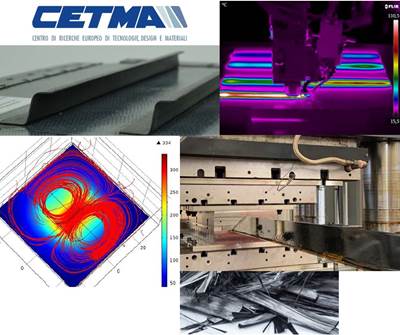

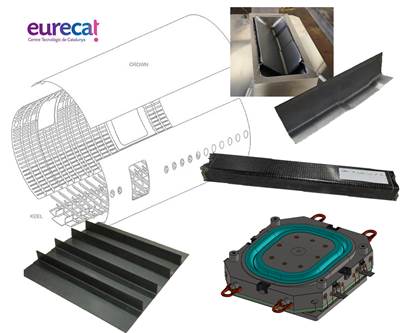

Leonardo Aerostructures, a leader in composites that produces one-piece fuselage barrels for the Boeing 787, is working with CETMA to develop new production technologies including continuous compression molding (CCM) and SQRTM (bottom). Source | Leonardo and CETMA

This blog is based on my interview with Stefano Corvaglia, materials engineer, head of research & development and IP manager of Leonardo Aerostructures Division (Grottaglie, Pomigliano, Foggia, Nola production facilities, southern Italy) and Dr. Silvio Pappadà, research engineer and head of programs with Leonardo at CETMA (Brindisi, Italy).

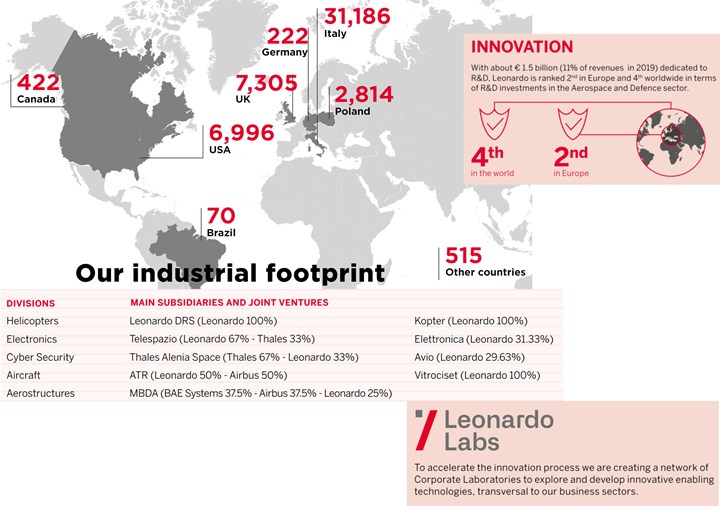

Leonardo (Rome, Italy) is one of the world’s major players in Aerospace, Defense and Security with 13.8 billion euros in revenues and 40,000-plus employees worldwide. The company provides comprehensive solutions on a global scale for air, land, sea, space, cyber & security and unmanned systems. With about € 1.5 billion (11% of revenues in 2019) dedicated to R&D, Leonardo is ranked 2nd in Europe and 4th worldwide in terms of research investments in the Aerospace and Defense sector.

Leonardo Aerostructures produces one-piece composite fuselage barrels for sections 44 and 46 of the Boeing 787 Dreamliner. Source | Leonardo

Through its Aerostructures Division, Leonardo provides fabrication and assembly of large structural components, including fuselages and empennages, in composites and traditional materials for the world’s major civil aircraft programs.

Leonardo Aerostructures produces the composite horizontal stabilizers for the Boeing 787 Dreamliner. Source | Leonardo

In composite materials, Leonardo Aerostructures Division produces “one-piece barrels” for the Boeing 787 central fuselage sections 44 and 46 at its Grottaglie plant as well as the horizontal stabilizers at its Foggia factory — totaling roughly 14% of the 787 airframe. Other composite structures production includes, at its Foggia Plant, fabrication and assembly of empennages for ATR and Airbus A220 commercial aircraft. Foggia also produces composite parts for the Boeing 767 and for military programs including the Joint Strike Fighter F-35, Eurofighter Typhoon fighter jet, C-27J military transport and Falco Xplorer, the latest member of the Falco family of unmanned aircraft produced by Leonardo.

Working with CETMA

“We have many ongoing activities with CETMA, for example, in thermoplastic composites and resin transfer molding (RTM),” says Corvaglia. “Our goal is to have R&D activities ready for production in the shortest possible time period. In our department (R&D and IP management), we also look to disruptive technologies with a lower TRL [technology readiness level – i.e., lower TRL is more nascent and further from production], but we look to be more competitive and assist our customers worldwide.”

“From the beginning of our work together,” adds Pappadà, “we have always looked to keep cost and environmental impact low. We have found that thermoplastic composites (TPC) offer a reduction in both versus thermosets.”

Corvaglia notes that, “together with Silvio’s team, we have developed these technologies and built some automated cell prototypes in order to evaluate these in production.”

Continuous compression molding (CCM)

“CCM is a good example of our work together,” says Pappadà. “Leonardo identified some components made in thermoset composites and together we explored technology to provide these in TPC, looking at where there are large numbers of parts in the aircraft, such as splice structures and stanchions with simple geometry.”

Parts made using CETMA’s continuous compression molding line. Source | “CETMA: Composites R&D innovation in Italy”

“We needed a new production technology characterized by low cost and high rate,” he continues. He points out that in the past, single TPC components were manufactured with a large amount of waste. “So, we produce net shapes based on non-isothermal compression molding but with some innovations (patents are ongoing) to reduce scrap. We designed a fully automated cell for this, which an Italian company then built for us.”

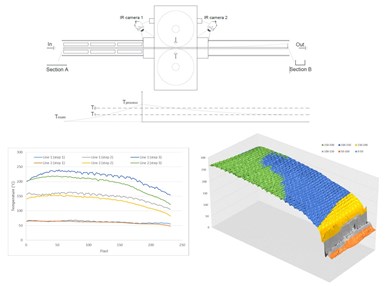

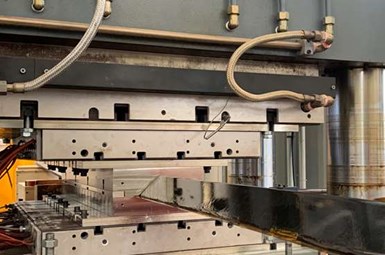

This cell is able to produce the components that Leonardo designed, says Pappadà, “at a rate of one component every 5 minutes, working 24 hours/day.” However, his team then had to figure out the production of the preform. “At the beginning, we needed a flat lamination process, for this was the bottleneck at that point,” he explains. “So our process starts with a blank (flat laminate), heats this in an infrared (IR) oven and then into a press for molding. Flat laminates are usually produced using big presses and require 4-5 hours cycle time. We decided to investigate a new method able to produce flat laminates in a faster way. Thus, we developed a high-productivity CCM line at CETMA with Leonardo engineers' support. We reduced cycle time for a 1-meter by 1-meter part to 15 minutes. Importantly, it is a continuous process, so we can produce unlimited lengths.”

Infrared thermography (IRT) cameras in the SPARE progressive roll forming line helped CETMA understand temperature distribution during production and generate 3D analyses to validate its computer models during CCM development. Source | “CETMA: Composites R&D innovation in Italy”

But how is this new compared to the CCM used for over a decade by Xperion,now XELIS (Markdorf, Germany)? “We developed analytical and numerical models able to predict defects such as voids,” says Pappadà. “We did this in cooperation with Leonardo and the University of Salento (Lecce, Italy) to understand parameters and their influence on quality. We used these models to develop this new CCM where we can have very high thickness but also high quality. Thanks to these models, we can optimize temperature and pressure but also how to apply these. There are a lot of technological aspects you can develop to have uniform distribution of temperature and pressure; however, we needed to understand the impact of these on the mechanical performance and growth of defects in composite structures.”

Pappadà continues, “Our technology is more flexible. Also, CCM was developed 20 years ago, but there is no information about it because the few companies who used it did not share knowledge and know-how. So, we had to start from nothing, just with our knowledge of composites and processing.”

“We are now working through internal programs and with our customers to find parts for these new technologies,” says Corvaglia. “These parts may be redesigned and requalified to start production.” Why? “The goal is to have an airplane as lightweight as possible but also price competitive. So, we must also optimize with thickness. But we might find out a part can go even lighter or identify multiple parts with a similar shape, which could enable significant cost savings.”

Until now, he reiterates, this technology has been in the hands of a few. “But we have developed alternative technologies to make these processes even more automated by adding more advanced press-forming. We put in a flat laminate and out comes a part, ready to go. We are in the phase of redesigning parts and developing flat versus shaped CCM.”

“We now have in CETMA a CCM line that is very flexible,” says Pappadà, “where we can apply different pressures as needed to achieve complex shapes. The line we will develop together with Leonardo will be more focused on components that fit its specific needs. We think we could have different CCM lines for flat panels and L-stringers versus more complex shapes. In this way, we can keep the equipment cost lower versus the big presses currently used to produce complex geometry TPC parts.”

CETMA used CCM to produce the stringers and plates from carbon fiber/PEKK unidirectional tapes and then joined them using induction welding for this keel beam demonstrator in the Clean Sky 2 KEELBEMAN project, managed by EURECAT. Source |“Welded thermoplastic keel beam demonstrator achieved”.

Induction welding for in-situ consolidation

“Induction welding is very interesting for composites because it’s possible to tune and control temperature very well, to heat very quickly and control very accurately,” notes Pappadà. “With Leonardo, we developed induction welding to join TPC components. But now we are thinking to use induction welding for in-situ consolidation (ISC) of TPC tapes. To do this, we have developed new carbon fiber tape that can be heated very quickly by induction welding using a dedicated machine. The tape uses the same matrix materials as commercial tapes but with a different architecture that improves electromagnetic heating. We are optimizing the mechanical performance but also thinking to the process, trying to match different needs, for example how to process cost-effectively with automation.”

He points out that ISC is very hard to achieve with TPC tape at good production rates. “In order to have this for industrial production, you must heat and cool faster and apply pressure in a very controlled way. So, we decided to use induction welding to heat a small region only where we are consolidating material but leave the rest of the laminate cold.” Induction welding used for assembly has a higher TRL, says Pappadà. “

Using induction heating for in-situ consolidation seems very disruptive — something no other OEMs or tier suppliers are doing openly at this point. “Yes, this is possibly disruptive technology,” says Corvaglia. “We have patented the machine and the materials. We are aiming for something that can be comparable to thermoset composites. Many have tried AFP (automated fiber placement) with TPC but have to do a secondary step for consolidation. This is a big limitation in terms of geometry, cost, cycle time and size of parts. We may indeed change the way to produce aeronautical parts.”

SQRTM

In addition to thermoplastics, Leonardo continues to look at RTM technologies. “This is another area where we have worked with CETMA and patented new developments based on an older technology, in this case, SQRTM. Same qualified resin transfer molding (SQRTM) was initially developed by Radius Engineering (Salt Lake City, Utah, U.S.). “To have an out-of-autoclave (OOA) method that allows us to use material that is already qualified is important,” says Corvaglia. “It also lets us use prepregs which have well-known properties and quality. We have designed, demonstrated and patented an aircraft window frame using this technology.”

CETMA continues to work on Leonardo programs despite COVID-19, shown here producing an aircraft window structure using SQRTM to achieve a defect-free component and speeding up preforming versus traditional RTM technology. Leonardo, thus, gains the ability to replace complex metal parts with net-shape composite components, for which no further processing is required. Source | CETMA, Leonardo.

“This also is older technology, but if you go on the web, you cannot find info on this technique,” notes Pappadà. “What is important is that, again, we are using analytical models to predict and optimize the process parameters. With this technology, we can have good resin distribution — with no dry regions or resin pooling — and near-zero void content. We can produce high structural performance because we can control fiber content, and this technology can be used to produce complex shapes. We are using the same materials qualified for autoclave cure, but instead in an OOA method, but you could also decide to use fast-curing resins to reduce cycle time to minutes.”

“Even with current prepreg, we have reduced the curing time,” notes Corvaglia. “For example, compared to a normal autoclave cycle of 8-10 hours, we can achieve 3-4 hours with SQRTM for a part like a window frame. Heat and pressure is applied directly to the part, and mass to heat up is less. Also, heating the liquid resin versus the air in an autoclave is faster and the part quality is outstanding, which is an advantage especially for complex shapes. There is no rework, near-zero voids and excellent surface quality because the tool is controlling it, not a vacuum bag.”

Visionary, technology-based future

Leonardo is producing innovation in a large and diverse set of technologies. Due to the rapid evolution of technology, it sees investment in high risk R&D (low TRL) as crucial to develop the new technologies required for future products, which go beyond the incremental (short term) development it already sustains in current products. Such a combination of short term and long term strategies are combined in Leonardo’s 2030 R&D Masterplan, a unified vision for a sustainable and competitive company.

As part of this plan, it is launching the Leonardo Labs, an international network of corporate R&D laboratories dedicated to advanced research and technology innovation. For 2020, the company will pursue opening the first six Leonardo Laboratories in the areas of Milan, Turin, Genoa, Rome, Naples and Taranto and is recruiting 68 researchers (Leonardo Research Fellows) with skills in the following areas: 36 positions in Artificial Intelligence and autonomous intelligent systems, 15 in big data analytics, 6 in high performance computing, 4 in electrification of aeronautical platforms, 5 in materials and structures and 2 in quantum technologies. Leonardo Labs will play the role of innovation outposts and generators of Leonardo's future technologies.

Notably, the technologies that Leonardo commercializes in aircraft may also have applications in its land and sea divisions. Stay tuned for more updates on Leonardo and its potential impact on composites.

Related Content

Plant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

Welded thermoplastic composite keel beam demonstrator achieved

EURECAT and partner companies complete Clean Sky 2 KEELBEMAN project, demonstrating TRL3 primary structure technology for future aircraft.

Read MoreCETMA: composites R&D and innovation in Italy

From design and simulation to inline inspection, induction welding, continuous compression molding and recycled carbon fiber, this lab to support industry is advancing composites in aerospace, automotive, construction and more.

Read MoreAdvancing thermoplastic composites and RTM for Clean Sky 2 in Spain

EURECAT leads projects for TPC keel beam, window frames and thermoset RTM fuselage frames with TPC shear ties for next-gen aircraft.

Read More