“Self-responsive” nanomaterial-based composites AMRC’s Matthew Collinson (top photo) inspects a composite demonstrator component incorporating carbon nanotubes (CNTs) and copper contacts to enable increased conductivity along an aerostructure. The goal is for the aerostructure to be easily heated in a controlled way for anti-icing. Photo Credit: AMRC

Multifunctional composites are, according to CW Senior Editor Ginger Gardiner in her 2018 article on the topic, “composite laminates that not only provide lightweight, load-bearing structures, but also perform additional functions.”

The list of “additional” functions, then and now, is almost endless. Structural health monitoring (SHM), anti-icing/deicing, impact resistance, acoustic damping, electrical conductivity, energy storage, transmissivity, radiotranslucency and thermal conductivity are just a few, not to mention self-healing and morphing functions.

Multifunctionality can be imparted in a variety of ways, generally through adding materials to the laminate in some way (conductive materials, wires, sensors, etc.) or — more difficult — altering the composite materials themselves (for example, adding nanomaterials into the resin matrix).

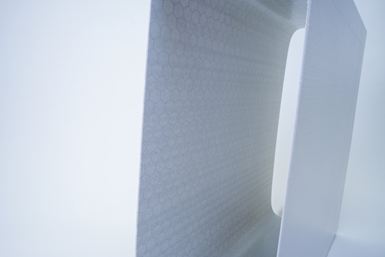

Multifunctional layers. Technical Fibre Products’ range of nonwoven veils can be incorporated into composite parts to impart a variety of functionalities, from EMI shielding (like the veil pictured) to fire resistance. Photo Credit: TFP

Multifunctional composite technologies also span the spectrum of commercialization, with some technologies having been around for decades, while others are just beginning to emerge in R&D labs. As one example, Technical Fibre Products (TFP, Schenectady, N.Y., U.S.) has been supplying multi-material nonwoven veils for years, which are integrated within the layers or on the surface of a composite part to add electromagnetic interference (EMI) shielding, conductivity, reflectivity, abrasion resistance or fire protection properties and more. At the same time, notes John Haaland, president of TFP, these veils can act as a flow media to ensure resin infuses properly throughout a part. Current application areas range from defense and telecommunications applications that require conductivity or dielectric tunability, to infrastructure and public transportation applications that need to be more fire-resistant, to wind turbine blades that require lightning strike protection.

Another highly commercialized functionality within composites is SHM for nondestructive testing (NDT) of a part either during manufacture and/or in service. This most often requires the integration of sensors within or on top of a part. Recently, CW has reported on innovations in this field including magnetic microwire sensors, piezo-ceramic transducers and more.

Two areas within multifunctional composites with new developments on the horizon that will affect a range of end markets are radiotransparent structures such as radomes, and anti-icing/deicing technologies.

Radomes: Structural and electrical performance

Enabling autonomous drone design. Skydio’s X2 autonomous drone required both high strength and radio transparency. For the pictured structural component developed by Arris, carbon fiber and glass fiber are combined into one consolidated part to enable all needed properties. Photo Credit: Arris

Glass fiber (and quartz fiber, a purer, higher performing form of glass fiber) is often used within applications that need the structural performance of a fiber-reinforced composite, but also the radio transparency of glass. Specifically, glass fiber has a low dielectric constant (Dk), or relative permittivity, which allows high-frequency waves from antennas or radar to pass through it with minimal electric power loss. Adjusting the thickness and other properties can tune the part for various applications.

For example, Arris (Berkeley, Calif., U.S.) designed a glass fiber “window” within the carbon fiber structure of an autonomous drone, which the company developed to enable the passage of signals from an antenna inside the drone through the exterior.

On a larger scale, the radio transparency of glass fiber has long made composites a multifunctional solution for radomes — protective/functional coverings over radar, antennas or telecommunication signaling devices. TFP supplies quartz fiber veils that can be integrated into composite radomes to control radio transparency — sometimes called dielectric — properties. The Baltimore, Md., U.S. location of aerostructures and defense components specialist Meggitt (Coventry, U.K.) is one company that designs, manufactures and tests radomes and antennas for aerospace, marine and ground applications. Meggitt most frequently builds radomes for military use, including applications such as electronic warfare, satellite communications (SATCOM), intelligence surveillance and reconnaissance and radar warning receivers.

Given the high-performance requirements needed for military applications, Meggitt typically uses quartz fiber/cyanate ester for its radomes, rather than lower cost glass fiber or epoxies. “Our parts are highly engineered and need to be able to handle high mechanical loads,” says Mike Stasiowski, director of advanced technologies at Meggitt Polymers and Composites. “For our products, we need the strength of fiber-reinforced materials, as opposed to a thermoplastic or other unreinforced radome, but it also has to be radio frequency [RF] transparent. It’s a challenge.”

Protection meets radio transparency. Meggitt uses quartz fiber composites to manufacture radomes for aircraft, such as the pictured wing tip pod radome (top) and wing leading edge radome (bottom). Both are highly engineered to protect antennas or radar systems while providing the needed dielectric properties to enable antenna performance. Photo Credit: Meggitt

The idea, says Stasiowski, is to design for both structural and electrical performance simultaneously. Radomes can be built from several basic designs, the simplest of which would be a one-material cover with uniform thickness. According to Stasiowski, today’s radar systems require the passage of more signals at wider frequency ranges than ever before, so multi-layered sandwich panels are often used to tune the thickness and materials of a radome to strike a balance between structural integrity, light weight and radio transparency.

The development of a radome for a customer requires the coordination of both electromagnetic and structural design, says Stasiowski: “It’s an iterative process, where the electrical team is doing their optimization, the mechanical team is doing their optimization, and there’s a lot of back and forth because mechanically you want a thicker structure, electrically you want a really thin structure and the answer is somewhere in the middle. Eventually, we end up with a design that meets all the requirements.”

Most of Meggitt’s composite radomes and antennas are manufactured via hand layup and autoclave cure, given the relatively small volumes and high-performance requirements. They range in size from “about the size of your hand,” according to Stasiowski, up to 15 feet long, or even up to 40 feet or more for multi-piece radomes.

While defense and aerospace remain core focuses, Meggitt does occasionally work on commercial SATCOM projects as well. For example, as displayed at JEC World 2019, Meggitt worked with fabrics, preforms and intermediates supplier Porcher Industries (Eclose-Badinières, France) to develop a SATCOM radome demonstrator using glass fiber composites and thermoplastics. Designed to house in-flight communications and entertainment systems on a commercial aircraft, the radome uses low-cost materials and several sandwich layers to deliver needed impact resistance as well as the ability to tune the Dk for optimizing 5G air-to-ground transmission.

Also in the commercial field, Exel Composites (Vantaa, Finland) has been manufacturing glass fiber-reinforced composite radomes for the telecommunications industry since the mid-1990s. Glass fiber, says Tiina Uotila, R&D engineer at Exel Composites, has always allowed the company to build lightweight, structurally capable protective components with the transparency to enable signal transmissivity.

Growing with 5G. According to Exel Composites, meeting the needs of evolving telecommunications networks (like 5G and beyond) has also meant required evolutions in materials used to build radome protective systems for telecommunications antennas, such as this 5G macro antenna radome. Photo Credit: Exel Composites

Over the years, telecommunications networks have evolved, requiring antennas to broadcast a wider range of frequencies. According to Uotila, 5G networks (and beyond) require the transmission of waves that are higher in frequency and shorter in wavelength. The shorter wavelength, she says, can transfer a lot of data, but has a relatively short range, meaning that more antennas are needed to cover the same area as 4G or LTE systems. For example, 5G requires one small-cell, millimeter-wave transceiver every 150 meters. Today’s telecommunications networks require installation both of larger, macro-cell base stations and large numbers of small cell transceivers, both of which require protective/radio-transparent radome structures. “There are very different frequency and protection requirements based on the size and location,” notes Uotila.

Exel’s 4G and 5G radome structures, which range in size from half-meter-wide 5G macro-tower radomes to small cell covers, are manufactured via pultrusion and feature a sandwich-based design with foam core. According to Uotila, Exel is able to manufacture the complete sandwich structure at once using pultrusion. “Depending on the application, the production volumes can be pretty high,” says Uotila. “We use pultrusion because it’s a continuous, cost-effective, consistently repeatable manufacturing method.”

Announced in February 2021, the company has also secured a new European patent for its telecommunications radome design incorporating closed-cell thermoplastic foam. Exel says it plans to extend the patent to North America and China as well. “The idea behind the new developments,” Uotila says, “is that you want to reduce the Dk of the material as much as possible [to account for higher frequency wavelengths]. The best thing, electrically, would be to have nothing blocking the signal from the antenna, but at the same time, you still need to protect the antenna.” Exel reduced glass fiber and resin content significantly through the use of porous core material in a sandwich construction. “This maintains the structural stability as much as possible, while bringing very good electrical properties and reducing overall weights. It’s always a compromise,” she adds. Developed over the course of four years, the radome design is said to be highly tunable to meet customer requirements.

Next-stage RF transparency

According to Stasiowski, one trend in the radome market going forward may be the integration of antennas in the radome structures themselves. Newer antennas, he notes, are “electronically scanned antennas, getting away from mechanically scanned antennas,” meaning that instead of having to be physically positioned so that a fixed beam points towards the target, beams can be steered electronically without moving the antenna itself. Since these antennas do not need to be physically moved after installation, they can, if desired, be directly embedded into the composite laminate.

Meeting volume needs with pultrusion 5G networks require the transmission of waves at higher frequencies but shorter wavelengths, requiring more antennas to be installed closer together to cover the same amount of space. This has led to higher production needs for manufacturers of protective radomes like this small-cell receiver cover, made via pultrusion. Photo Credit: Exel Composites

He adds, “It’s an interesting challenge, because now you’ve got metal being embedded into a composite structure, and you’ve got the different coefficients of expansion and all of those types of things that are trying to fight you. But ultimately, I think antennas and radomes will become one for at least some applications that really want it — like aircraft.” He adds that on aircraft, a typical antenna and protective radome protrude from the surface on which they are mounted, but an integrated antenna/radome design would not require an additional surface-mounted structure. “You don’t want a bump on the outside of your airplane if you can avoid it,” Stasiowski says.

Also working in this field is the 11-partner EU Horizon 2020-funded program ACASIAS (Advanced Concepts for Aero-Structures with Integrated Antennas and Sensors), in which researchers are developing “smart” aircraft fuselage panels and winglets that integrate various forms of very high frequency (VHF) antennas within composite laminates (read about the fuselage panels in senior editor Ginger Gardiner’s “Integrating antennas into composite aerostructures”).

In addition, carbon fiber composites, in combination with other materials, are also being considered for next-generation RF-transparency/structural functionality. For example, Carbon Mobile (Berlin, Germany) won the 2021 JEC Composites Connect Innovation Award for its carbon fiber smartphone design, Carbon 1 MK II. The phone is manufactured from Carbon Mobile’s patented HyRECM (Hybrid Radio Enabled Composite Material) technology, which is said to fuse carbon fibers with a “complementary composite material capable of RF signal permeation” and a 3D-printed conductive ink.

Thermoelectric materials: Structural performance and anti-icing/deicing

Multifunctional ice protection Ice accumulation can cause significant structrual damage on helicopters and other aircraft. Several research programs are working with composites and nanomaterials to increase the anti-icing or deicing properties of structural composite helicopter blades, airplane wings and other aerostructures. Photo Credit: Airbus Helicopters

Structural damage caused by the accumulation of ice is a chronic challenge for any structure that flies in the air, sits high off the ground or is located in a climate where temperatures occasionally dip below freezing. Such structures include exterior aerostructures, wind turbine blades and bridges. As many of these applications are increasingly manufactured from composite materials, adequate prevention of ice formation (anti-icing) and ice removal (deicing) has become a necessity for structural composites.

Common forms of anti- or deicing include chemical sprays or conductive coatings on the part surface that can then be heated to prevent ice formation. According to Fabien Dezitter, icing expert at Airbus Helicopters, within the aerospace industry a common anti-icing strategy for large, turbine-powered aircraft is to direct hot air from the engines — called bleed air — into the aircraft’s wing leading edge, heating the surface to prevent ice formation. “The system is quite simple, but it has low heating efficiency,” Dezitter says, “and is not always compatible with complex geometries or composite components.”

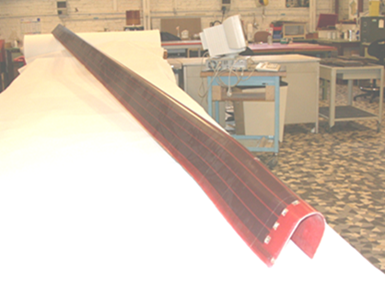

Thermoelectric anti-icing systems for rotor blades Currently, Airbus Helicopters’ Fabien Dezitter says several technologies of electro-thermal ice protection are available, with electrical resisters made of metallic mats, carbon fibers, or manufactured by metal deposition. The pictured helicopter rotor blade de-icer consists of heater mats made by superimposing different numbers of carbon layers. Airbus and partners are now researching the addition of graphene to heater mats as a more efficient and versatile material option for helicopters and large aircraft. Photo Credit: Airbus Helicopters

For helicopter rotor blades and tail rotors, electrothermal ice protection systems — in the form of heater mats made from resistive materials — may be integrated into blades to add ice protection functionality into the components.

According to Dezitter, though efficiency improvements are needed for current electrothermal ice protection systems to make them suitable for large aircraft, they may be an enabling technology for next-generation aerostructures. “In the future, we are going to have new aircraft configurations, moving to more electrical aircraft and helicopters, with more composite components. There are also new regulations, especially for large aircraft when we have other types of icing conditions to be considered. We are looking for continuous improvement of the technology, of our ice protection system and our overall product,” he says.

Integrating heater mats for added conductivity

One product, launched by Qarbon Aerospace Inc. (Red Oaks, Texas, U.S.) in July 2021, is called Helios Ice Protection. Helios consists of a thermoplastic/carbon fiber heating element with a layer of graphite, embedded within a thermoplastic composite leading edge structure for use on an aircraft wing, nacelle or empennage. The company recently partnered with AIR Group for global distribution of the technology, specifically targeting airlines operating turboprop aircraft.

New icing protection technology for turboprop aircraft. Qarbon Aerospace’s newly launched thermoplastic composite-based Helios Ice Protection system is designed to mount onto a wing or other component of a commercial turboprop (model shown here). Photo Credit: Qarbon Aerospace

In development, the graphene-based thermoelectric ice protection system (GICE) project was launched in April 2020 to improve the thermal efficiency and versatility of electrothermal ice protection systems for next-generation, composite-based aircraft and helicopter components. Led by Airbus Helicopters and European Union-sponsored research initiative Graphene Flagship, the program also involves partners Airbus Commercial Aircraft (Toulouse, France), the Airbus Research and Technology Center, Sonaca Group (Charleroi, Belgium), FIDAMC (Madrid, Spain), Versarien PLC (Cheltanham, U.K.), Nanesa (Arezzo, Italy), FORTH (Heraklion, Crete, Greece), Consiglio Nazionale delle Ricerche (Rome, Italy), the University of Cambridge (Cambridge, U.K.) and Universite Libre de Bruxelles (Brussels, Belgium).

The researchers chose to work with graphene, Dezitter says, to take advantage of both the material's conductivity properties and also its versatility: The material characteristics can be controlled with different amounts of materials to tune for different power density or other requirements of a given application. The GICE project is working to develop a graphene-based heater mat system for integration within composite aerostructures like aircraft wing leading edges and helicopter rotor blades, with the goal of producing a versatile system that enables more precise control of heat generation to prevent ice formation. GICE researchers also aim to automate and reduce the cycle time for the manufacturing process for composite components with integrated ice protection systems. By the project’s end in September 2023, the main deliverables for GICE will be three demonstrators: A helicopter rotor blade, an aircraft leading edge and an air inlet with complex 3D geometry.

In the first year, GICE researchers worked on material optimization and production of the graphene material to be used for the heater mats. “We need to not only produce the quantity and form we need for the application, but to demonstrate that we are able to control the material characteristics as well,” says Dezitter, who is one of the project leaders. The rest of 2021 will be spent developing the heater element.

The ultimate goal is to create a sandwich-type construction comprising the graphene heater element, an insulating material and electrical connectors layered together and then integrated within the composite laminate. Along with graphene in the form of paper sheets and graphene ink, the mat can include other materials to tune resistivity, resistance and other material characteristics as well. By early 2022, GICE researchers aim to produce small-scale airfoil demonstrators based on several configurations to be tested in an icing wind tunnel. “This will give us our first assessment of the performance of the system compared to the state of the art. We’ll then narrow down the material configurations we’ve developed to the best candidate, which will then be integrated into the three main demonstrators,” Dezitter says. The goal is TRL 4 by the end of 2023.

The biggest challenge for the anti-icing scenario, Collinson notes, may be in part design.

Another project, the Clean Sky 2 program InductICE, which ran from 2016-2019, presented an alternative heater mat option, integrating ultra-thin metal mesh into composite aircraft wings. The wing could then be heated via electromagnetic induction to efficiently and inexpensively melt ice or prevent icing.

CNT-based composites for ice protection

Though not as far along, researchers are also investigating the use of nanomaterials directly within resin matrices as an anti-icing solution. Fibers, especially carbon fibers, are naturally conductive by themselves, while resins are typically insulative. The idea is to add conductive nanomaterials such as carbon nanotubes or graphene within a resin matrix to enable a fully electrically and thermally conductive part.

For example, begun in mid-2019, an EU Horizon 2020-backed initiative called MASTRO aims to develop “self-responsive” composite materials, focusing on three technologies: self-anti-icing, self-cure and self-sensing technologies for use within automotive, infrastructure and aerospace applications. MASTRO is being undertaken by 16 partners within industry and academia, with the University of Sheffield Advanced Manufacturing Research Centre (AMRC, Rotherham, U.K.) leading the aerospace branch with industrial partner Embraer (São Paulo, Brazil).

According to Matthew Collinson, a research engineer at the AMRC who coordinates the MASTRO project, the researchers, working with materials supplier Arkema (Colombes, France), are adding carbon nanotubes (CNT) into the thermoset resin matrices of carbon fiber composite components, and then integrating copper connection points into the part itself. The idea is that the CNTs will boost the conductivity of the typically non-conductive resin, enabling electrical currents to pass through the laminate to heat the copper connection points. This heat at strategic areas along the part can be used for curing resins during manufacture, preventing ice formation or, with the addition of sensors, SHM.

The biggest challenge for the anti-icing scenario, Collinson notes, may be in part design — making sure the copper connection points are integrated correctly and in optimum positions to adjust the amount and position of electrical currents for the specific application. However, this method would be a lighter-weight alternative to integrating metal mesh or heater mats into parts, he says.

Along with anti-icing, as part of this program the researchers are also working on self-sensing technology, using flexible printed circuit boards (PCB) to enable parts to monitor electrical resistance changes to detect barely visible impact damage that may be difficult to detect through visual inspection. “We don’t see this as a replacement for existing NDT systems, just as a complement,” Collinson notes. “If this was used on an aircraft, our system will be able to tell you to look at a certain area of a wing part to the nearest 20 centimeters for an impact, then inspection methods such as C-scan can fully characterize the damage.” In separate research, the AMRC is also investigating distributed SHM via fiber optic cables integrated within woven fabrics, prepregs and bonded joints.

Another focus on self-cure capability stems from a MASTRO project goal of curbing greenhouse gas emissions within the manufacturing process. The researchers aim to develop a faster, cheaper, less energy-intensive alternative to autoclave cure. This out-of-autoclave (OOA) approach would also eliminate the part size limitations of an autoclave or an oven. Materials being investigated include Solvay’s (Alpharetta, Ga., U.S.) CYCOM 5320 carbon prepreg and Chomarat (Le Cheylard, France, U.S.) dry carbon fiber with Huntsman (the Woodlands, Texas, U.S.) resin.

The overall MASTRO project ends in September 2021, by which time the AMRC will have built and tested the final version of a demonstrator airfoil incorporating this technology. Collinson says the center intends to continue its work in this area even after MASTRO concludes, working toward more complex parts.

Looking ahead, innovators continue to push toward new functionalities in composite materials, from multifunctional satellite sandwich panels being developed by DLR within the space industry, to Exel Composites’ pultruded rods with integrated fiber optic sensors for the oil and gas industry. In addition, electric vertical takeoff and landing (eVTOL) vehicles and electric vehicles (EVs) may present new opportunities for multifunctional composites in the near future (see sidebars below).

Ultimately, from automotive batteries to aircraft wings and beyond, companies and researchers are continuing to innovate by adding functionalities into structural composite parts. And, perhaps more importantly, the number of these technologies reaching commercialization, such as anti-icing, self-sensing and radiotransparent technologies, is also increasing, with more innovations to come.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read MoreMidnight production aircraft completes full transition flight

This is Archer’s second full-scale eVTOL aircraft to achieve this milestone, critical to being able to carry commercially viable passenger payloads.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;width=70;height=70;mode=crop)