Natural fiber enables e-bike for package delivery

New parcel delivery vehicle concept employs a natural fiber prepreg for low weight, vibration dampening, non-conductivity and flame retardancy.

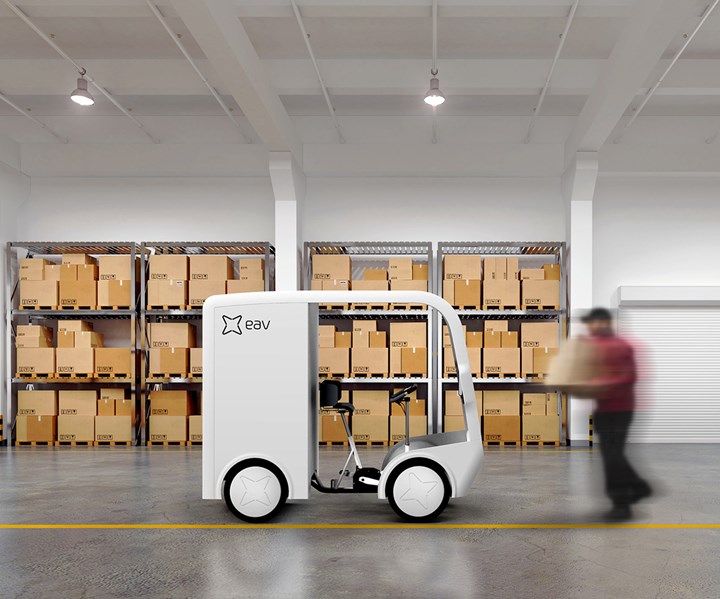

EAV set out to design its natural fiber eCargo bike as a scaled down light commercial vehicle (LCV) rather than an up-engineered bicycle. Source | Electric Assisted Vehicles Ltd.

With rising concerns about air pollution and urban congestion, there is a rapidly growing market for zero-emissions vehicles. A new British manufacturer, Electric Assisted Vehicles Ltd. (EAV, Oxford, U.K.), has unveiled its new eCargo bike project with the goal of helping to transform urban package transport. The company assembled a team of engineers from the automotive, motorsports and aerospace industries to create the bike — actually a quadracycle — which will be used to deliver products while addressing sustainability and urban mobility concerns.

The eCargo bike, which the company calls Project 1 (P1), is made from flax natural fiber composites. SHD Materials (Sleaford, U.K.) produces a custom prepreg for EAV using natural fiber from Bcomp Ltd. (Fribourg, Switzerland). EAV has some experience with the material, as it has been producing natural fiber composite parts for ProDrive Motorsports (Banbury, U.K.) for use on the Aston Martin Vantage GT4.

Adam Barmby, founder and technical director at EAV, says that depending on design requirements, natural fibers work as well as glass or carbon fiber. In addition to offering weight savings, the inherent properties of the natural fiber, which is non-conductive, vibration-damping and flame-retardant up to 300°C, are a good fit for electric vehicles such as the P1.

“The bike offered a natural opportunity to use [natural fiber],” he says. “It lends a green priority to manufacturing that hopefully people are going to want to see in the future.”

EAV’s eCargo bike can be steered and pedaled like a traditional bicycle and is narrow enough to fit on a bike path. Source | Electric Assisted Vehicles Ltd.

EAV says it approached the project with a light commercial vehicle (LCV) concept in mind rather than conceiving it as an up-engineered bicycle. The resulting vehicle weighs 12-15 kilograms, can be steered and pedaled like a traditional bicycle, and is narrow enough to fit on a bike path yet can hold up to a 150-kilogram payload. The P1’s chassis design is modular and can be widened or extended for a range of applications. The goal is to give operators many of the elements of a delivery van with increased efficiency and zero emissions.

A thumb switch on the P1 allows it to accelerate up to 9.7 kmh. Peddling the bike turns a crank that provides electric assistance for longer journeys or for uphill travel. The bike is reportedly compatible with all charging stations and is designed with removable battery packs that aid in charging, replacing and updating.

With the design engineering for the bike completed, EAV has turned its attention to the aesthetics of the P1. In collaboration with industrial design company New Territory (London, U.K.), the company is exploring a flax finish concept similar to that of the Tesla Model S.

“We would like to re-educate the population on common-sense vehicle design and intelligent methods of mobility that deliver a sense of purpose and place for urban populations,” Barmby says. “We’re already thinking on how we can extend the technology for other uses.”

EAV’s P1 concept was developed in collaboration with the international parcel delivery service DPD (Aschaffenburg, Germany), which is testing the bikes at its all-electric parcel depot in London.

Related Content

Bio-based SiC ceramics from wood polymer composites

Austrian research institute Wood K plus makes 95% silicon carbide ceramics more sustainable (>85% bio/recycled content), enables 3D shapes via extrusion, injection molding and 3D printing.

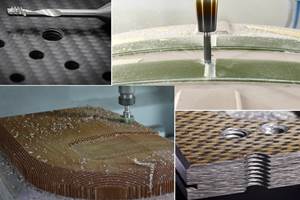

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreNASCAR unveils BEV prototype featuring natural fiber bodywork

Implementation of Bcomp technical flax fibers in a U.S. motorsport first represents NASCAR’s step toward more sustainable competition vehicles.

Read MoreNotox surfboards harness flax fiber for wave surfing competition

Libeco flax, Airbus rCF fabrics, Sicomin GreenPoxy bioresins and an agave core form a heavy, robust surfboard custom-designed for Clément Roseyro in this year’s Nazaré Big Waves Surf event.

Read MoreRead Next

UPS to deploy fleet of composite EVs in London, Paris

UPS is working with UK firm ARRIVAL to develop a pilot fleet of 35 composites-intensive electric delivery vehicles that will be trialed in London and Paris.

Read MoreAirbus begins Skyway drone shore-to-ship trials

The trials mark the first time unmanned air vehicle (UAV) technology has been deployed in real port conditions to deliver parcels to working vessels at anchorage.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More