New infusion regime for superthick laminates

Innovative initiator chemistry yields long flow time, cure on demand and exotherm control for large, thick parts.

It’s the holy grail of infusion: an unsaturated polyester or vinyl ester resin that allows unlimited flow time to vacuum infuse very large, thick parts, cures on demand and produces parts with mechanical properties equivalent to epoxy. Sound impossible? In fact, it is now a reality.

“We have been able to develop a cure initiation system, and the necessary processing steps, that allows for the manufacture of large-profile parts using highly energetic vinyl ester resins,” says Andre Cocquyt, president of Advanced Composites Services for Manufacturers Inc. (ACSM) and sister company GRP Guru, both located in Brunswick, Maine.

Cocquyt is the program manager for a collaborative effort aimed at improving production of corrosion-resistant parts. Program participants include ACSM, chemicals specialist Arkema Inc. (Philadelphia, Pa.) and molder Kenway Corp. (Augusta, Maine). Resin manufacturers Cook Composites & Polymers (CCP, N. Kansas City, Mo.) and Interplastic Corp. – Thermoset Resins Div. (St. Paul, Minn.) are also aboard as development partners.

The linchpin in the program is new patented BlocBuilder nitroxide-mediated, controlled radical polymerization (NM-CRP) technology, developed by Arkema. It provides the basis, says Cocquyt, for a processing system “that allows fast and efficient infusion of large parts that cure without stress.” Indeed, the technology won an American Composites Manufacturers Assn. (ACMA) ACE Award for innovation at the COMPOSITES 2009 exhibition and conference in Tampa, Fla., and industry interest, since, is running high.

The chemistry behind controlled radical polymerization

To understand how NM-CRP technology has changed the infusion landscape, a review of thermoset polymer cure is in order. Simply stated, a thermoset resin requires heat, a catalyst, or a combination of both to achieve cure. Typically, a small amount of peroxide initiator (the catalyst) is added to a solvent, such as styrene, and mixed with a polyester or vinyl ester resin. The functional groups that branch from the resin backbones react with the free radicals created by the peroxide to form covalent bonds, or crosslink. This irreversibly joins the polymer chains together to form a solid. For epoxies, a curative called a hardener is added, rather than a peroxide, to crosslink the epoxy rings and complete the cure. Many factors enter into the selection of initiators, hardeners and other additives, depending on the resin formulation, the process, the type and size of part, its performance specifications and more.In resin infusion processes, the cure process and additive choices get more complicated, particularly for very large parts cured at low or room temperature. Resins designed to cure at room temperature typically have a very short pot life, or working time, yet to infuse a part like a large boat hull or wind turbine blade using only vacuum pressure, the resin must remain highly fluid during the entire time required to wet out the part. To achieve the long pot life and very low viscosity, additives and modifiers are used. For example, vinyl ester typically requires a reduction-oxidation initiation system, such as methyl ethyl ketone peroxide (MEKP), for low-temperature cure. But, to induce the chemical decomposition of the initiator, an accelerator or promoter, such as cobalt octoate, must be added to the mix. Additives called inhibitors also are needed to prevent premature gel or cure of the resin during the mold fill cycle, says Dr. L. James Lee of Ohio State University (Columbus, Ohio). Epoxy resins are even more problematic: unmodified epoxies have a viscosity of several thousand centipoise (cps). The addition of amine hardeners can reduce viscosity to about 1,000 cps, but to achieve viscosity in the 250 to 400 cps range that is required for infusion, reactive diluents, such as glycidyl ether, are used to induce room-temperature gelation, often making cure and exotherm (the generation of heat due to the chemical crosslinking process) difficult to control. Besides adding considerable formulating and processing complexity, additives and modifying compounds can affect the mechanical performance of the cured resin, particularly in the case of epoxy cured at room temperature, notes Cocquyt.

BlocBuilder technology provides an alternative to these highly reactive and difficult-to-control resins, says Arkema’s Michael Wells, a functional additives applications engineer. First recognized and developed by Dr. Krzysztof Matajazewski of Carnegie-Mellon University (Pittsburgh, Pa.), who gave it the CRP moniker, nitroxide-mediated CRP starts with a traditional initiator (e.g., organic peroxide) to generate free radicals as it decomposes. The initiating radicals transfer their single-electron radicals to an unsaturated molecule, either the double bond of the backbone polymer or the styrene monomer. During this process, the radical species converts from an oxygen type to a carbon-centered type. Then, says Wells, a secondary additive takes over — the nitroxide, which is a unique molecule synthesized by Arkema with a single, stable, freely reactive, unpaired electron. “Nitroxides are unreactive to oxygen, so they react only with the carbon-centered radicals,” he explains. “This is significant, as it doesn’t really matter how you generate the initiating radical — the nitroxide only becomes involved with the radicals that have attached to polymer chain molecules or monomers.”

The resulting nitroxide/monomer bond is an intermediate molecule called an alkoxyamine, with a temperature-dependent chemical equilibrium. At room temperature, says Wells, a lower energy state exists, such that the alkoxyamine simply remains dormant and coupled with the radical, effectively trapping the latter. But, when energy is added to the system in the form of heat, the reaction energy shifts; the nitroxide begins to slowly release from the bond sites in an alternating trap-and-release fashion, sequentially allowing monomers to join the growing polymer in a controlled manner, adds Wells. “The heat controls the rate of propagation as well as the molecular weights of the crosslinks that form,” he explains.

“The end result is a resin system that is stable for long periods of time at ambient temperatures or even slightly elevated temperature, but reacts when needed with the addition of modest heat,” says Wells, noting, “The amount of heat needed is much lower than that typically required to cure an infusion epoxy system.” He adds, however, that the activation temperature depends on the combination of the nitroxide and whatever monomer is selected. Therefore, the temperature will differ when something other than styrene is used or a comonomer system is preferred.

Producing thick laminates

The upshot for fabricators is that BlocBuilder offers unprecedented control of vinyl ester (and polyester) resins during infusion, says Cocquyt. Because this includes control of exotherm during cure, infusing very thick laminates is now a practical option. He and the project partners have spent considerable time and resources conducting detailed tests of BlocBuilder-modified resins, producing structural laminates of various thicknesses on temperature-controlled molds designed by ACSM. Says Cocquyt, “We discovered that we can manipulate vinyl ester resin properties via thermal control during and after infusion.”The project partners wanted to demonstrate four key scenarios for vacuum infusion: 1) virtually unlimited flow time, 2) cure on demand, 3) controlled exotherm regardless of part thickness, and 4) good mechanical properties equivalent to infused epoxy. To accomplish these goals, a series of infusion tests were designed using simple stacks of fiberglass wet out with Epovia RF1001L vinyl ester resin from CCP or 8100-50 vinyl ester resin supplied by Interplastic. Both resins were modified with BlocBuilder IS300 additive combined with Arkema’s Luperox brand peroxide initiator. Cocquyt is careful to point out that there is no generic additive recipe that will work in any situation for any part: “The formulas we used were determined by Arkema, working with the two resin vendors. A different resin system will require its own testing to determine the best ratios.”

With regard to flow time, the team first worked with neat resin alone, in small batches of 100 mL/3.4 oz. The initial definition of “unlimited” flow time was 24 hours at room temperature or two hours at 105°F/41°C, at which temperature the vinyl ester resin has a viscosity of a mere 50 cps. By tweaking the additive recipe, Cocquyt maintains, the group achieved stable viscosity and no gelation for more than 70 hours at room temperature and more than eight hours at 105°F/41°C. BlocBuilder can be added separately or in combination with the Luperox additive. Wells reports that a single combination pack of both additives, called Luperox IS300, will be available soon for infusion applications.

Next, three stacks of plain-weave fiberglass cloth, at 2, 4 and 6 inches in thickness (51 mm, 102 mm and 152 mm), were placed on a flat-table mold equipped with a single heating zone. One 50-lb/28.7-kg batch of modified resin was used to simultaneously infuse all three stacks, under a single vacuum bag. The experiment was conducted three times: once at low fiber volume (30 percent), once for an average fiber volume (50 percent) and again for a high fiber volume of 70 percent plus. The high-fiber-volume stacks incorporated some 55-oz/1.56-kg unidirectional material interleaved with some biaxial plies to simulate heavy beam caps for a theoretical wind energy application. After completing the infusion of the stacks, with infusion time taking anywhere from 6 to about 19 minutes, cure was initiated by increasing the temperature of the mold and, thus, the laminate stack. An insulated box was placed over the stacks to control the laminate environment. Cocquyt explains that as the program progressed, the temperature control was decreased to achieve gelation at the lowest possible temperature. “Early in the program, gel was initiated by setting the mold temperature at 170°F [76.7°C],” he notes. “By the end of the program, we could initiate gel within the stacks at a maximum of 140°F [60°C] within 30 minutes of completing the infusion, proving that cure on demand was possible with the temperature trigger.” The lower temperature also means that lower-temperature mold materials are possible, saving tooling costs, and that large portable ovens built around very large parts don’t have to reach excessive temperatures.

Perhaps most exciting is the ability to control exotherm during cure, particularly in the thicker 6-inch/152-mm laminate stacks. Exotherm is a natural characteristic of thermoset resin cure. But, in a typical peroxide-initiated cure, uncontrolled thermal “runaway” can easily occur — an ever-faster decomposition of the initiator as the temperature rises, which generates more oxygen, which stimulates further temperature increases. Escalating temperatures lead to hot spots, short and irregular crosslinking, and subsequent stress fractures in the cured laminate (or in the worst case, a fire).

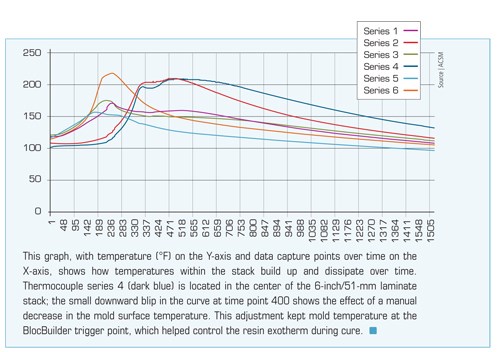

To test the exotherm behavior of the BlocBuilder-modified resins, thermocouples were embedded within the 2-, 4- and 6-inch stacks to monitor heat ramping. In the graph on p. 37, the thermocouple data demonstrate that the sequential unblocking of the crosslink sites credited to BlocBuilder results in a smooth and gradual temperature rise and a subsequent decrease as exotherm dissipates. Cocquyt points out that the small dip in the violet line (the thermocouple in the center of the 6-inch laminate stack) represents a manual downward adjustment of the mold temperature controller. Here, the rate of exotherm immediately slowed as the mold temperature decreased slightly, demonstrating tremendous control of the process.

“This to me is the key to moving the technology forward,” stresses Cocquyt. “The success of CRP technology in infusion is joined at the hip with the development of a mold technology that allows meticulous mold temperature control, as opposed to simple heated-mold technology, which does not work, as we learned a few times during our testing.” In other words, although any type of heated mold would suffice to trigger the onset of the nitroxide release from the crosslinking sites, a high-output thermal control mechanism is necessary to modulate and control the mold’s surface temperature as the cure progresses — keeping it at, but not above, the trigger temperature is the key to controlling the exothermic energy.

Better mechanicals

Lastly, the modified vinyl ester resins produce laminates with properties superior to conventional vinyl esters and room-temperature-cure infused epoxies, claims Cocquyt. Independent testing conducted at the University of Maine’s AEWC Advanced Structures and Composites Center (Orono, Maine) using the ASTM D2344 Short-Beam Strength (SBS) method showed that short-beam strength for traditional glass/vinyl ester laminates (postcured for 16 hours) ranged from 4,300 to 5,300 psi (29.7 to 36.5 MPa), consistent with general industry data. The BlocBuilder-modified vinyl ester specimens were 6,000 to 6,500 psi (41.4 to 44.8 MPa), or 28 percent higher. Values also appear to be considerably higher when compared to infused epoxies, which (as previously noted) require additives for room-temperature flow and cure that affect their cured properties.“The mechanical property experiments showed a marked increase in performance — the very low viscosity during infusion, coupled with the CRP cure mechanism, may improve the fiber/resin bond,” asserts Cocquyt. “This is something that we intend to investigate further.”

One outcome of the project has been the establishment of a new division within Kenway, called TCM Composites, which is manufacturing temperature-controlled closed-mold units that it will offer customers for testing the BlocBuilder technology. Kenway also intends to convert much of its own heavy industrial composite parts production to the temperature-controlled molds and CRP-modified resins, says Kenway’s VP and general manager, Ian Kopp. Significant investment has been made in the mold technology, including funding from the Maine Department of Economic and Community Development (DECD), and Cocquyt’s company is developing a training curriculum for fabricators interested in learning more.

“This technology is straightforward but not ‘simple,’” concludes Cocquyt. “Our own long learning curve confirms that there is a certain degree of finesse required, which will come through hands-on education.” In the near future, this technology is certain to have far-reaching implications for large, thick structural parts in the infrastructure, industrial and corrosion-prevention markets.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreBraskem demonstrates PP solutions using Weav3D composite lattice technology

Partnership combines Braskem’s polypropylene sheets with Weav3D Rebar for Plastics technology to address new structural, automotive applications requiring high-strength, lightweight material solutions.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)