One for the history books?

HPC editor-in-chief Jeff Sloan wonders if a current and radical proposal for change in the way aerospace materials and processes are certified — namely, certification of design/simulation software — will find the brave advocates it will need to become a watershed in aerocomposite history.

My wife teaches U.S. history at our local high school, so my three boys and I are often immersed in whatever era she’s currently exploring with her students. That’s especially true now that one of her students is our middle son, so a large fraction of our family is consumed by the civil rights movement, the Progressive Era, Reconstruction, slavery, the Civil War, a World War or some other significant even.

The study of history is, in many ways, the study of human evolution (or devolution, depending on your point of view). And as we gaze back through time, of course, we have the certainty of hindsight: We know how the story ended. But for the people living through big and small events, outcomes were most uncertain. The primary actors throughout history have played their parts with a courage we often can’t appreciate because they risked much for their beliefs, with at least some doubt about how events would unfold.

I call this the Uncertainty of Living, and it’s as applicable to you and me in the high-performance composite industry as it was to the historically famous and infamous. A variety of economic, market, creative, technological and simply human forces exert evolutionary pressure on composites manufacturers and their customers. Advances in fiber and tape placement, combined with resin and fiber innovations, made possible the once unthinkable application, in new ways, of carbon fiber to the Boeing 787 and Airbus A350 XWB.

In this issue of HPC, you’ll find several articles that shed light on aspects of aerospace composites design and manufacture that are in need of evolutionary prodding. The first, by senior editor Ginger Gardiner, focuses on efforts to develop certifiable adhesively bonded composite aerostructures (see "Certification of bonded composite primary structures," under "Editor's Picks," at top right). To meet current certification requirements, bonded primary structures are also mechanically fastened to ensure their long-term performance. Of course, there is no word more freighted with meaning in the aerospace industry than “certification.” Adhesive bonds that are deemed by the FAA to be as safe and durable as those fixed with mechanical fasteners are far from certain.

Our Market Trends columnist, Purdue University’s Dr. R. Byron Pipes, also picks up the certification theme, advocating an evolutionary nudge away from the time-consuming, expensive physical testing now required during aircraft certification, toward what could someday be certification based on virtual testing (see "Accelerating the certification process for aerospace composites," under "Editor's Picks").

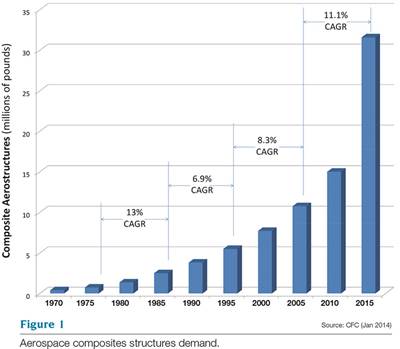

Chris Red, in his Market Outlook on out-of-autoclave (OOA) aerostructures (see "The market for OOA aerocomposites, 2013-2022," under "Editor's Picks"), does his own look back through aerocomposites history. He then explores market, material and technical hurdles to be cleared if the fast-evolving OOA processes are to earn their way on to A320 and 737 replacements.

Finally, technical editor Sara Black, in her Focus on Design (see "Thermoplastic composites save weight in rotorcraft tailplane," under Editor's Picks"), details design and development of the carbon fiber/thermoplastic composite tailplane fabricated for the AgustaWestland AW169 helicopter. She highlights the mechanical challenges posed by the application and how thermoplastics have proved their mettle. Thermoplastics, it would seem, are poised to become a major material force for years to come.

These material, software and process possibilities, and others like them, hold much promise, but will demand much courage from their advocates. Who among us will persist in pursuit of them despite uncertainty and, in some quarters, great skepticism? Will we (or our kids) someday look back on those who make history in aerocomposites and, in hindsight, take quite for granted these now quite unlikely outcomes? My educated guess is yes.

Related Content

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreSmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

Read MoreMFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreRead Next

Accelerating the certification process for aerospace composites

Columnist Byron Pipes foresees the certification of simulation software in place of physical testing.

Read MoreThe market for OOA aerocomposites, 2013-2022

In the coming decade, out-of-autoclave technologies will increase composites penetration into primary flight structures.

Read MoreCertification of bonded composite primary structures

OEMs develop technology to quantify uncertainty in pursuit of the no-bolt bondline.

Read More

.jpg;maxWidth=300;quality=90)