SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

SmartValves are shown at far left and far right, with traditional two-piece vacuum ports in between. Photo Credit: SmartValves, Bert Groenewoud, Earth and Flight Composites.

SmartValves were developed by Bert Groenewoud, a composites technician, instructor and process development engineer with more than four decades of experience in composites fabrication and repair. The valves he developed were in response to issues he experienced during complex vacuum bagging for aircraft structures.

Groenewoud’s experience with composites fabrication and repair is significant. He served as a sheet metal and composites specialist at KLM for 16 years, an advanced composites and metal-bond repair instructor for 13 years and senior process development engineer at Airborne Composites for almost 6 years. A member of the Commercial Aircraft Composite Repair Committee (CACRC) since 1991, Groenewoud is now owner and operator of Earth & Flight Composites a composite repair training company near Amsterdam in the Netherlands which has two composite repair training facility locations in Germany at HEICO Aircraft Maintenance in Leipzig and 4Uexperts in Frankfurt.

“I started working on SmartValves after my years at KLM, while serving as a materials and process engineer at Airborne,” says Groenewoud. “I had long been frustrated by issues with tilting of standard vacuum ports. For example, such ports connect to long and heavy vacuum hoses, which then pressed into the vacuum base plate hole and closed off the valve.”

Standard vacuum ports use a base plate underneath the vacuum bag. In order to attach the top assembly — which has a connection fitting for vacuum hoses — a hole is cut into the vacuum bag at the center of the base plate and the top assembly is twisted to tighten.

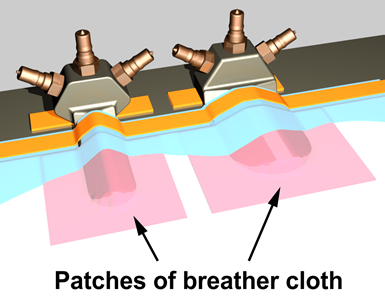

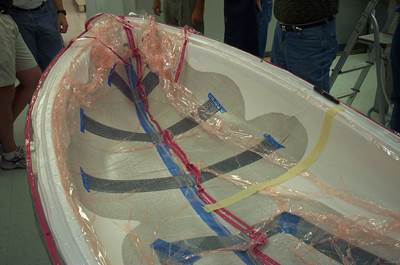

SmartValves are installed at the edge of a vacuum bag (blue), using breather cloth and sealant tape (yellow). Photo Credit: SmartValves, Bert Groenewoud, Earth and Flight Composites.

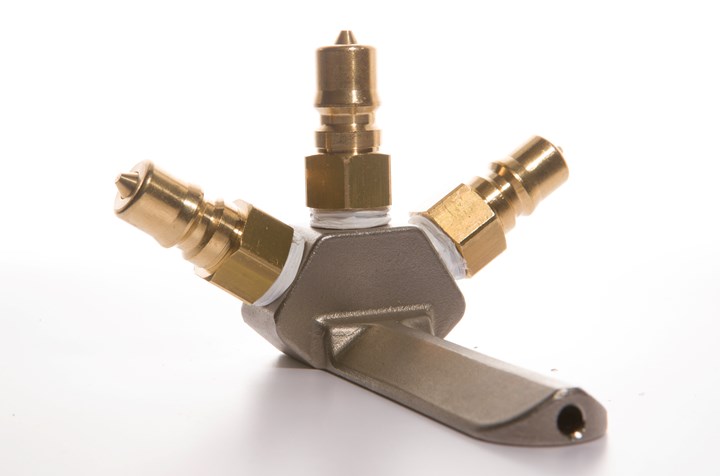

“The SmartValves design eliminates tilting issues by using a flat stainless steel base with channels inside that lead directly to the connect/disconnect fittings,” says Groenewoud. “This design also eliminates pressure points. To install, simply place the valve plate at the edge of the flat or curved area, then cover with a breather ply and the vacuum bag film with sealant tape. Press down to seal the valve plate on both sides and across the top. SmartValves don’t tilt, whereas standard valves must have vacuum applied to avoid this. Even with a vacuum gauge and heavy hoses connected, the Smart Valve stays upright. Plus, you don’t cut the bag and, if you use precut bagging film, you can eliminate the risk of having razors or scissors in the bagging area.”

Groenewoud claims SmartValves provide cost savings by reducing the time to complete vacuum bagging, as well as a longer service life and reduced maintenance due to the one-piece, stainless steel design — the main body of the valve is covered by a lifetime guarantee. SmartValves also resist high temperatures (up to 1,200°F/649°C) and can be applied to flat and curved surfaces and used with all standard vacuum couplings and gauges.

SmartValves are distributed by GMI Aero (Paris, France) and come with a certificate of fabrication. Questions can also be directed to Bert Groenewoud at Earth and Flight Composites.

Related Content

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

Read MoreCompPair adds swift prepreg line to HealTech Standard product family

The HealTech Standard product family from CompPair has been expanded with the addition of CS02, a swift prepreg line.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreRead Next

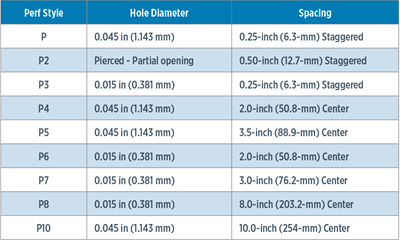

Tech Table: Vacuum bagging supplies

This is the fifth in a series of Tech Tables and comprises vacuum bagging material data provided by suppliers.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More