Part design criteria (2015)

Designers of composite parts can choose from a huge variety of fiber reinforcements and resin systems. That makes knowledge of how those materials work together a critically important aspect of part development. Here's a short description of what that knowledge entails.

Designers of composite parts can choose from a huge variety of fiber reinforcements and resin systems. Knowledge of material properties is a prerequisite to satisfactory product design, but cost is a major factor, as well. Overdesigned composites cannot compete with lower-cost, established material systems. A well-designed part that uses composites’ anisotropy not only employs the right materials and processes to meet application requirements but, many times, can be commercially competitive with a product made with competing materials that are less expensive in terms of raw material cost (steel, aluminum, etc.), when installation and lifecycle costs (maintenance, repair, the impact of a longer useful life) are considered.

In any design, the fiber reinforcements provide the greatest portion of the composite’s mechanical properties, such as stiffness and strength, while the matrix — a polymer resin or an alternative, such as a ceramic) provides physical characteristics that can include toughness and resistance to impact, weather, fire, ultraviolet (UV) light and/or corrosive materials (also see "Composites: The materials and processes," in "Editor’s Picks," at right).

A significant design consideration is fiber-to-resin ratio, which is a determining factor in the ultimate weight and cost of the component and governs the extent to which performance properties inherent in the fiber reinforcement can be optimized in the part. Fiber-to-resin ratio can range from 20:80 for low-cost, nonstructural components to as high as 70:30 in some high-end structural parts. A 60:40 or higher ratio is common in advanced composites.

Three additional factors must be considered when designing with fiber: fiber type, fiber form and fiber orientation or architecture. Orientation refers to fiber direction in relation to the longest part dimension. Typically, fiber architecture is tailored in the direction of the primary loads placed on a structure, a design principle comparable to what civil engineers use to orient steel reinforcing bars in a concrete structure. Common orientations are parallel (longitudinal or 0°), circumferential (90°) and helical (usually ±33° to ±45°). However, fiber direction can vary greatly. For example, a 54° winding angle satisfies both the circumferential (hoop) and longitudinal (axial) strength requirements of most pipes and pressure vessels, usually manufactured by the filament winding process. However, if more stress is placed on the pipe in the axial direction, as is the case with an unsupported span, a ±20°/±70° fiber orientation will provide a stiffer bending modulus for increased axial strength.

Composites, by nature, enable designers to tailor fiber architecture to match the performance requirements for a specific part. Laminates may be designed to be isotropic (to imitate the performance of legacy materials) or anisotropic, balanced or unbalanced, symmetrical or asymmetrical — depending on the in-use forces a component must withstand (italicized terms are defined in our “Glossary of Terms”).

An understanding of layered or laminated structural behavior is vital to effective composite component design. Adhesion between laminate layers (called plies) is critical; poor adhesion can result in delamination under stress, strain, impact and/or other load conditions.

Ply layup designers must consider mechanical stresses/loads, adhesion, weight, stiffness, operating temperature and toughness requirements, as well as variables such as electromagnetic transparency and radiation resistance. Using composites, designers freedom to vary fiber orientation and adjust the number of ply layers at any point in a laminate to meet local performance requirements. Wall-thickness, for example, can be varied, thicker where stresses or loads are high and thinner where they are low. This makes it possible to minimize weight and realize complex shapes and produce large parts with integral reinforcing members.

Additionally, composite component design must account for the desired surface finish, fatigue life, overall part configuration, and scrap or rework potential, to name just a few of the many applicable factors.

The intended fabrication method also will influence design. For example, manufacturers of filament-wound or tape-layed structures use different reinforcement forms and buildup patterns than those used either for laminate panels layed up by hand or for autoclaved prepreg parts. Resin transfer molding (RTM), which is one of several processes that employs a two-piece, fully enclosed mold, accommodates three-dimensional preforms more easily than do some other manufacturing techniques. RTM, in fact, is capable of producing a part with a predictable finish on 100% of its exposed exterior surface. It is also capable of producing complex 3D parts. For example, Hollow parts with at least one opening can be made in one piece, with a finished surface on both exterior and interior, through the use of removable (collapsible or inflatable) inner tools called mandrels. The choice of production method and type of tooling must be made with part desired geometry, aesthetics, part performance requirements and production run length in mind (see "Fabrication methods (2015)" and “Tooling (2015)” under “Editor’s Picks," at right).

A common type of composite structure — sandwich construction — combines a lightweight core material with thin laminated composite skins (facesheets), similar to the construction of corrugated cardboard. These cored panels have the highest stiffness-to-weight and strength-to-weight performance of all composite structures and are extremely resistant to bending and buckling. Suitable core materials include closed-cell foams, balsa wood and celled honeycomb in a variety of forms (aluminum, paper or plastic). Some foam cores are syntactic, that is, they contain hollow microspheres to reduce weight. Sandwich construction is used extensively on modern aircraft and boats as well as in applications such as cargo containers and modular buildings.

Some material suppliers offer reinforcements with an integral core, such as a core-like material (e.g., foam rods) stitched together with glass or carbon fibers. This combination — a woven or unidirectional fiber form integrated with a core material — provides a unitized composite structure that is amenable to both infusion and closed-mold processing.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRead Next

The Basics Of Boat Design

Naval architects reveal design, tooling and material selection guidelines for a new sportfishing powerboat.

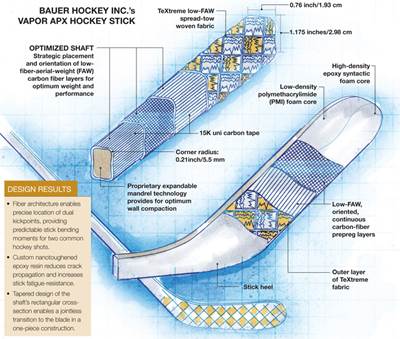

Read MoreAdvanced hockey stick design delivers optimal performance

Carbon fiber composites and an innovative new resin system play key roles in the design of an elite-level stick.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)