Advanced hockey stick design delivers optimal performance

Carbon fiber composites and an innovative new resin system play key roles in the design of an elite-level stick.

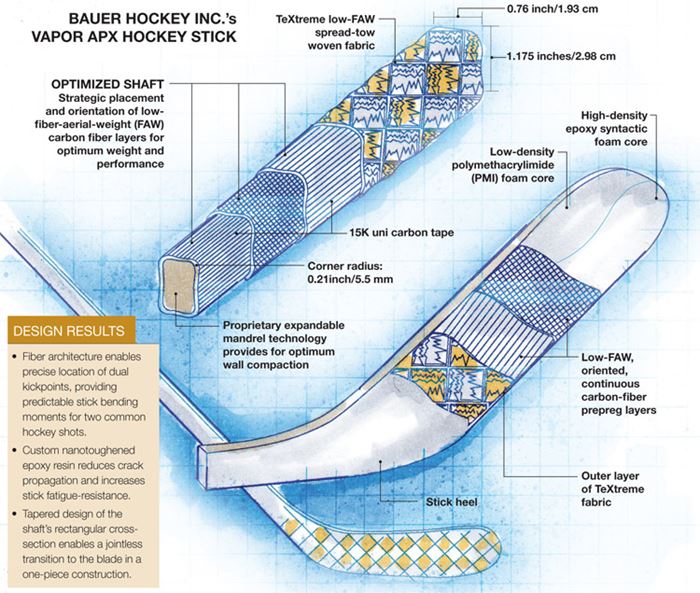

Design Results:

- Fiber architecture enables precise location of dual kickpoints, providing predictable stick bending moments for two common hockey shots.

- Custom nanotoughened epoxy resin reduces crack propagation and increases stick fatigue-resistance.

- Tapered design of the shaft’s rectangular cross-section enables a jointless transition to the blade in a one-piece construction.

At one time, a hockey stick was like Henry Ford’s all-black Model T: you could get any size or style of stick you wanted, as long as it was wood. The introduction of composite sticks in 1999, however, enabled designers to build sticks 35 percent lighter than their wood predecessors and perfect once impossible stick designs that have since changed the game. A notable example is the VAPOR APX stick from Bauer Hockey Inc. (Greenland, N.H.). The stick (launched in fall 2011) tops the VAPOR product line, which is one of Bauer’s two lines for the retail market. It differs from the company’s more conventional TOTALONE stick (launched a year earlier in the company’s SUPREME product line) in terms of blade structure, shaft shape and its stiffness profile, or what hockey players call the kickpoint.

The kickpoint is the point on the shaft at which the stick flexes during the act of shooting the puck. Unlike other composite sports equipment — such as tennis rackets and golf clubs, which are swung in a simple pendulum motion and (ideally) contact only the ball — a hockey stick is swung in a more forceful, linear motion (see photos) and the blade hits the ice, intentionally, some distance behind the puck. Here, the kickpoint allows the stick to bend, thus storing and transferring a significant amount of energy. The stick reaches its maximum bending moment before the blade hits the puck. When it contacts the puck, the stored energy is released during the follow through. In general, a composite hockey stick must be able to withstand a nonlinear dynamic load of 1,000N to 1,200N for 1.2 seconds without fatigue in the fiber matrix during 1,000-plus cycles.

Like the majority of retail sticks, the TOTALONE is designed with a single kickpoint near the middle of the shaft. The APX, however, features two kickpoints, a performance feature Bauer markets as Intelli-Sense Shot Technology. Kickpoints are designed into composite sticks by making the shaft stiffer in some areas (by adding layers of reinforcing material in strategic locations) and more flexible in other areas (by using less material or by reorienting the fibers). The stiffest region of the VAPOR APX is about 18 inches/457 mm above the stick’s heel, with more flexible regions below and above, yielding two areas of flex: one about 10 inches/254 mm below the point of maximum stiffness and the other the same distance above it.

Adam Gans, Bauer’s director of product development, explains that the dual-kickpoint design accommodates hockey’s most common shots — the slap shot and the wrist shot. During a slap shot, a heavier load is applied to the shaft and the low hand position is below the stiffest section to take advantage of the kickpoint nearest the ice. The distance and, therefore, the time between initial contact with the ice and contact with the puck is short, resulting in a quicker shot. During a wrist shot, the low hand is positioned above the upper kickpoint, so the shaft bends in two places, maximizing energy storage. Thus, the player can transfer more energy to the puck.

Fiber architecture

A standard hockey stick shaft has a hollow, rectangular cross-section. The cross-sectional dimensions of the upper portion of the VAPOR APX are 0.76 inch by 1.175 inches (1.93 cm by 2.98 cm), with radiused corners (radii of 0.21 inch/5.5 mm) on each of the shaft’s four edges. The VAPOR APX stick’s standard length is 60 inches/1.52m. A long and complex series of tapers are built into the lower region of the stick to connect the wider shaft to the thinner blade.

Gans explains that, beyond weight, there are three major stick design criteria. First, the materials must be able to store and release energy quickly, which is why certain grades of carbon fiber are advantageous. Second, the shaft must have a stiffness profile that complements a player’s biomechanics to optimize shooting capacity. Third, the blade must damp impact well enough to ensure that the puck will stay on the blade while the player is shooting or receiving a pass, yet it also must provide enough sensation to allow the player to feel where the puck is on the blade.

The VAPOR APX comprises four main components: the stick’s shaft core, the shaft’s outer layer, the shaft taper and the blade. The shaft is built up around a proprietary expandable mandrel. The shaft core features 13 to 15 layers of material, 4 inches to 60 inches (102 mm to 1,524 mm) in length, laid down in an alternating sequence of orientations. The layers are high-strength, standard-modulus, low-FAW (fiber aerial weight) unidirectional (UD) 15K carbon fiber prepreg tape supplied by Mitsubishi (Toyohashi, Japan). Designers specify that material should be layered to a particular thickness.

“The more layers you have, the more you can distribute the orientation of the fibers,” says Gans. The orientation sequence in a core cross-section follows a pattern (e.g., 30°/45°/30°/19°/0°/30°), and the pattern varies depending on the area of the stick and its specified stiffness profile. “When you have a good distribution of fiber angles, you have a better distribution of stress,” explains Gans, noting that more layers of 0° fiber increase linear stiffness; more layers of 45° fiber increase torsional stiffness; and more layers of 90° fiber increase resistance to buckling. The VAPOR APX architecture is designed to impart optimal resistance to fatigue. Although the dual-kickpoint architecture is proprietary, Gans reports that the company “uses localized inserts with specific fiber orientations to achieve the high-modulus zone at 18 inches [457 mm] from the stick’s heel.”

For the VAPOR APX, Bauer collaborated with Mitsubishi on the development of eLASTech, a toughened epoxy-based resin system that incorporates carbon nanotubes and thermoplastic nanoparticles. Gans says the formulation impedes crack propagation and resists interlaminar shear better than toughened resins that feature other additives, such as liquid rubber. “When you get a load that is parallel to the laminate, it’s the epoxy that’s going to take that load,” he explains, “so it’s important to have a toughened resin that resists fatigue and increases the longevity of the stick.”

The shaft’s outer layer is a single ply of FAW100 TeXtreme Spread Tow fabric, which is supplied to Mitsubishi by manufacturer Oxeon AB (Borås, Sweden), then impregnated by Mitsubishi with eLASTech resin for the core’s UD layers. Oxeon’s spread-tow fabrics are produced by weaving spread-tow tapes. Two of the fabric’s main benefits are reduced weight and extremely low crimp that increases mechanical properties compared to a standard 3K woven fabric. Another advantage is greater compatibility with the inner prepreg layers. “TeXtreme fibers, which are relatively flat, are adjacent to the UD layers, which are absolutely flat,” Gans observes. “The mechanical commonality creates less stress, so there is less likelihood of shearing between the two layers.”

Gans claims that Bauer is the only hockey stick manufacturer that uses a “mono-comp” molding process in which the VAPOR APX and SUPREME TOTALONE sticks are each molded in one piece in a single shot. The process is more complicated than molding a blade and a shaft separately, but it eliminates the weight penalty paid in the more common two-part process where the shaft and the blade are adhesively bonded at a mortise-and-tenon joint, which adds weight where it is least desired, skewing the kickpoint and adding unwanted stiffness at the attachment point.

The design of the shaft’s taper facilitates the dual-kickpoint action and allows the manufacture of an integrated structure in a single shot. Below the 18-inch point of maximum stiffness, the rectangular cross-section of the shaft begins to taper in two directions: from side to side (the narrower cross-sectional width) and from front to back. Gans emphasizes that the goal is to make the taper thin enough to provide the shooter with the desired bend and whipping action, but not make it so thin that the transitional region is subject to high forces of torque, which can cause the stick to twist and result in loss of shot precision. He explains that the shaft-to-blade transition zone was carefully tuned by modifying the taper’s layup and UD fiber orientations in the area, and by optimizing the geometry.

The shaft core terminates at the stick’s heel, where it mates with the blade core. Here, Bauer uses two types of expandable foams. A low-density foam is used in the portion of the blade that receives fewer impacts, that is, at the intersection of the shaft and the heel of the blade. A syntactic epoxy foam with high shear strength, developed by Bauer in-house, is used in the blade body. The blade’s outer layer is formed from the same spread-tow fabric prepreg used for the shaft’s outer layer. The VAPOR APX stick is sold with eight blade pattern options, each of which has its own individual length, height and curvature. Most blades are 8 inches to 9 inches long (20.3 cm to 22.9 cm) and 2.5 inches (6.36 cm) high, with a thickness that varies from 0.350 inch (8.8 mm) at the heel to 0.150 inch (3.8 mm) at the toe.

Bauer “tech packs” — which include the detailed layup sequence of the inner UD prepreg layers, woven outer layer and blade core materials — are assembled in-house at the company’s R&D facility in St. Jerome, Quebec, Canada. The combination of narrow rectangular shapes (and corner radii) and multiple tapers presents a manufacturing challenge that is met by precise control of preform assembly and molding conditions to prevent bridging and voids in the laminate. Tech packs are shipped to China, where they are compression molded using Bauer’s proprietary molding technology, which is designed to optimize compaction of the core’s laminate walls. Postmold operations include sanding then applying a clearcoat, decals and a final layer of clearcoat. The stick is then ready to put the puck in the net.

In addition to its retail product lines, Bauer designs custom sticks for NHL athletes and other elite players. Knowledge gained in custom stick design informs the company’s retail product strategies. This spring saw the launch of a third Bauer product line, headlined by the NEXUS 1000, an all carbon-fiber stick with a “Tru-Mid” kickpoint that has enjoyed great success in pro sticks for several years on NHL ice.

Related Content

Jeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreBio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreRead Next

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More