AvCarb, based in Lowell, Mass., U.S., traces its history back 50 years to NASA’s Apollo program. The company at that time was called AVCO and made a name for itself developing AVCOAT, an ablative material used to fabricate heat shields for the Apollo capsules. AvCarb leveraged that technology to develop graphitic fabrics and papers for use in hydrogen fuel cell systems, which is the primary focus of the business today. Photo Credit: CW

For the vast majority of applications of carbon fiber-reinforced polymers (CFRP), performance metrics revolve around lightweighting and structural properties, such as strength, stiffness, durability, toughness, crack resistance, corrosion resistance, weatherability and more. These have been and always will be the hallmarks of CFRP performance.

There is one application, however, where carbon fiber’s properties are deployed in a different, non-structural, but just as important way — in which high-quality carbon fiber-based products help maximize the power generating capability, and material forms manage the reactants of a electrochemical fuel cell reaction. That application is the hydrogen fuel cell, and the carbon fiber product it uses is the gas diffusion layer (GDL), a thin,highly-engineered carbon fiber paper composite, and a critical component in the fast-growing and rapidly evolving effort to leverage hydrogen as a tool to decarbonize the world’s energy supply.

As important as GDLs are to fuel cells, there are only a few companies in the world that have the experience and chemical and manufacturing expertise required to produce them at sufficient quality and quantity. One of those companies is AvCarb, located in Lowell, Mass., U.S., and the focus of this plant tour.

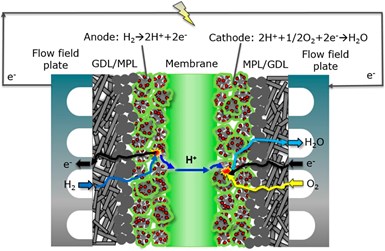

Fig. 1. Fuel cells come in a variety of sizes and designs, but all follow the same basic principle. Hydrogen enters the cell from the left via a flow field plate, passes through the GDL/microporous layer (MPL), enters the cathode and reacts with a catalyst (usually titanium). The catalyst separates the hydrogen into electrons (e-) and and ions (H+). Electrons travel through a circuit that creates electricity. Ions travel through the central electrolyte membrane and enter the cathode, on the right. Electrons, after creating electricity, enter the cathode with oxygen from external air delivered via another flow field plate on the right. The ions, electrons and oxygen come together in the cathode to form water, which is emitted from the fuel cell as waste. AvCarb’s specialty is the manufacture of the carbon fiber GDL. Photo Credit: Jasna Jankovic, Ph.D., Materials Science and Engineering Dept., University of Connecticut.

Fuel cells 101

To understand AvCarb, its manufacturing processes and its products, one first has to have a basic understanding of a fuel cell — its components and operation. Fuel cells come in a variety of sizes and types, providing electrical power in drivetrains in myriad vehicles, including passenger cars and trucks, buses, long-haul trucks, trains and ships. They also can be used to provide stationary power to residential structures and commercial buildings.

Regardless of the application, all fuel cells operate in the same fundamental way, consuming hydrogen and using an electrochemical reaction to separate electrons from protons in each hydrogen atom. Following this separation, electrons are routed through an external circuit to produce electricity, before being moved to the end of the process and the cell, where they unite with the hydrogen protons and oxygen to produce water.

It’s important to understand the specific components of a fuel cell to appreciate the role AvCarb’s products play. It might be easiest to think of a fuel cell as two nearly identical back-to-back halves, each of which uses the same materials to perform different functions (Fig. 1). On one side — left side, in Fig. 1 — is a flow field plate through which hydrogen is channeled. After it exits the flow field plate, the hydrogen passes through the carbon fiber GDL (which includes a microporous layer — MPL), a thin graphitic layer that acts as a moisture control barrier as well as an electrode that diffuses the hydrogen before it passes through the anode layer. The anode layer is coated with a catalyst, typically platinum, that separates hydrogen electrons from hydrogen ions (protons). The protons are allowed to pass through the electrolyte at the center of the fuel cell and into the cathode. The negatively charged electrons are channeled through an external circuit, where they generate an electric current.

Meanwhile, on the right side of the cell is another flow field plate through which air is channeled before it passes through its own GDL/MPL and then a cathode. Inside the cathode, the disparate particles and atoms meet — hydrogen protons from the electrolyte, hydrogen electrons from the external circuit, and oxygen from the air — to produce water molecules, which are then expelled from the fuel cell as waste.

Fig. 2. AvCarb made a name for itself in the automotive industry in 1994 when it developed the friction surface for a General Motors transmission flywheel. Visible here as the narrow band of material around the perimeter of the flywheel, the friction material, made with carbon fiber/phenolic, proved uniquely durable. Photo Credit: CW

The efficiency of a fuel cell depends on its ability to convert as many hydrogen atoms to electricity as possible, and the GDL is a big part of this effort. The GDL must consistently and effectively diffuse the hydrogen across its surface to maximize the effect of the titanium catalyst on the anode. And that’s where AvCarb comes in.

From friction to fuel cells

CW’s tour of AvCarb starts in the company’s conference room, where we are met by Guy Ebbrell, president, and Roger Masse, CEO. If there is institutional memory at AvCarb, then it exists almost entirely in the form of Masse, who has worked for the company for 47 years, starting third shift doing basic production work and then gradually moving up the ladder to the leadership position he holds today.

Masse relates the company’s history, which goes back to the early 1960s, when AvCarb started life in Lowell as Aviation Corp., or AVCO. AVCO is best known for having developed AVCOAT, an ablative material used in the thermal protection system for NASA’s Apollo space program. AVCOAT 5026-39G consisted of an epoxy-novalac resin system reinforced with quartz fibers and phenolic microballoons. It was injected into a glass fiber honeycomb core that was bonded to the entire outer shell of an Apollo crew module. That entire system — honeycomb core infused with AVCOAT — provided critical thermal protection for astronauts in the crew module.

AvCarb, meanwhile, was developed as a brand within AVCO, consisting of carbon fiber composite structures fabricated for space, defense, friction, textile, and other applications, where many benefited from the carbonization technology on which the company was founded. AVCO also still marketed its heat shield material. In the 1984, AVCO was acquired by Textron and the AvCarb brand lived on.

Masse says AvCarb’s next big application came in 1994 when it was approached by General Motors, which was designing a new automatic transmission torque converter to help isolate engine vibrations and provide smooth torque converter apply-and-release operations (Fig. 2). One important attribute of this new design was to allow the torque converter to continuously slip in a controlled manner, and conventional friction materials at the time were inconsistent. AvCarb designed a woven carbon fiber/phenolic friction material that ultimately provided the consistency and durability needed for the life of the transmission. This successful design enabled GM to realize the full benefit of their new technology. Masse says AvCarb’s solution demonstrated consistent 2% torque convertor slippage for more than 300,000 miles. This friction material was so successful that GM specified it on all of its 4- and 6-speed transmissions for the next 20 years and eventually licensed it to Ford Motor Co.

“That drove a 5-7% fuel efficiency gain on 100 million vehicles produced,” Ebbrell says. “So that's a significant innovation. And that's the beginning of how we started to have a really positive environmental impact.” AvCarb remains a global leader in friction products today.

Also in the 1990s, AVCO started to look at carbon fiber’s potential in electrode technologies. “Although all the friction business kept going strong, we really started putting all our R&D efforts into fuel cells,” Masse says. “It was certainly a new market, but it was a fledgling market. It was very small. But it gave us an opportunity to start looking at different properties and technologies. It was gas flow versus liquid. We were used to dealing with transmission fluids, a much more viscous fluid. Now we're dealing with water and gas and we needed to design porosity of a different type. So we were adding particles in. We were dealing with all different types of graphitic materials. It was fun. I mean, it was a whole new type of composite for us — really a lot more complicated. Everybody had a different fuel cell design.”

This led to work in crystal formations and carbon/carbon by certain types of heat treatment, porosity development for GDLs, fabrics manufacture and more. “Our expertise was in managing material thickness, porosity, crystal formation and heat treatment,” Ebbrell says. “That was and is our sweet spot and fuel cells needed these properties. They were right up our alley.”

Fig. 4. Following the stretch-breaking process, oxidized carbon fibers are spun as yarn onto these yellow bobbins. These fibers will eventually be woven to create fabrics for fuel cell applications. Photo Credit: CW

That alley, however, was thick with onerous material requirements. “We learned pretty quickly that the GDL is absolutely critical,” Masse says. “It has to be chemically inert. It has to compress the right amount and not too much. It cannot physically degrade. It has to be really conductive and let that current go around the external circuit. And then, here you are generating all this water. The GDL needs to be able to dispel that water without drying the membrane out because the membrane must stay wet — but not too wet. In all, it is a very complicated high-performance composite structure that is fully graphitized and unique in the industry.”

As AVCO entered the fuel cell market with its graphitic carbon fiber fabrics and papers for GDL applications, Textron decided to focus solely on defense work and sold the company to Ballard Power Systems (Burnaby, B.C., Canada) in 2001. At the same time, AVCO spun off its boron fibers business with the creation of Specialty Materials (Lowell), which still operates today and produces boron and silicon carbide fiber products. The AVCO name went away as the company became Ballard Material Products, but the AvCarb brand survived. Ballard subsequently challenged AvCarb to deliver a world class gas diffusion system for Ballard’s fuel cell systems, which AvCarb did.

In 2013, however, Ballard went through a divestment phase of its own and sold the AvCarb brand and technology to the current management team, backed by private investors. The AvCarb brand thus became AvCarb the company, and for many years it focused on diversification of products and markets and expanding its GDL expertise for hydrogen applications. Then, in late 2021, private equity firm Arsenal Capital Partners (ACP, New York, N.Y., U.S.), recognizing the growing importance of fuel cells in general as part of their sustainability push in their growth fund, and AvCarb’s unique capabilities in particular, acquired AvCarb with the promise of significant capital investment. Since ACPs investment in late 2021, AvCarb has invested significantly in capacity, R&D, and customer service to support the anticipated rapid growth of AvCarb’s fuel cell and other energy material forms. By early 2023, AvCarb will have installed and commissioned the world’s largest asset base for servicing the GDL needs of a growing global customer base with even more investment planned.

Today, AvCarb’s fuel cell products represent a large majority of the company’s revenues and clearly a significant demand driver for the future. Masse notes that fuel cell technology is evolving quickly, with a variety of increasingly complex designs entering the market — different shapes, sizes, principles of operation — that demand different GDL features and performance attributes.

Its become incumbent on AvCarb to meet those needs. Masse points to AvCarb’s unique mix of electrochemists, material scientists and design engineers, who help the company stand out and drive the innovation needed to keep it ahead of the fuel cell technology curve. “Our goal is to be the number one provider of engineered carbon-based products in growth areas that are impactful to the planet’s future,” Masse says. “To do that, we have to stay ahead of the market technically, with sufficient capacity, and be ready to address our customers’ needs as they seek higher performance and global supply chains.”

The AvCarb product line

AvCarb’s products fall into one of four broad categories: fabrics, papers, gas diffusion systems, molded graphite laminates, felts and friction materials. All of these products are manufactured using AvCarb’s proprietary carbon fiber graphitization process and each is targeted at a specific application, with many of those in the fuel cell/energy generation market.

Fabrics are manufactured in roll format and are targeted toward gas transport, motion control and high-temperature applications. Carbon fiber papers, also manufactured in roll format, are nonwovens that feature a porous carbon matrix and are targeted toward specialty batteries, fuel cells and electrolyzers. Gas diffusion systems are carbon fiber papers in laminate format with polytetrafluoroethylene (PTFE) and other coatings, targeted specifically toward GDL applications in proton exchange membrane (PEM) fuel cell systems. Molded graphite laminates comprise thicker and stronger carbon fiber papers and are targeted toward electrode-backing applications in demanding environments. Felts, offered in roll format, are targeted toward electrode applications in flow battery systems, an emerging and maturing electrolytic energy production system. Finally, friction materials, offered in sheet format, comprise the same carbon fiber/phenolic combination that won over GM. These materials are still targeted toward vehicle transmission applications.

The feedstock for almost AvCarb’s products takes two forms: oxidized polyacrylonitrile (PAN) yarn or nonwoven carbon fiber paper. The use of these raw material is central to AvCarb’s manufacturing expertise as it gives the company complete control over the heat treatment process, which is critical to development of the material properties demanded by fuel cell and similar energy systems. The use of oxidized PAN and nonwoven carbon fiber paper, combined with the nature of the end products, also means that AvCarb’s manufacturing floor looks very different than a typical composites fabrication operation.

Fig. 5. Oxidized carbon fibers are unwound from spools and onto the “beamer” mandrel. These fibers will become warp fibers in the weaving process, which follows. Photo Credit: CW

“There are very few companies in the world with the combination of capabilities and expertise that we have, and now with the resources and vision of Arsenal Capital Partners, we are doubling our capacity in 2022 in Lowell, and actively planning for further expansion globally. In addition, we are accelerating R&D to stay ahead of the needs of future generations of fuel cell stacks under development,” Ebbrell says. “AvCarb’s value proposition and customer focus is difficult to match. We are absolutely committed to the success of the hydrogen and alternative energy economies.”

Stretch-breaking, weaving, coating

Our tour of the 155,000-square-foot AvCarb facility begins in the noisy Textile Room where, as the name implies, fibers are received and begin their journey toward becoming fabric. Here, oxidized PAN is drawn in thick, black, continuous bundles from red, cylindrical containers and into the first of two stretch-breaking machines (Fig. 3). These machines pull the fibers over a series of rollers to bring them into tension sufficient to break each one. The result is a thick bundle of broken fibers called a sliver (pronounced “sly-ver”). After the sliver exists the first stretch-breaking machine, it’s passed through another, which breaks the fibers a second time.

“What happens is the fiber enters the machine and the downstream rollers go faster than the other three rollers,” Ebbrell says. “They are literally snapping the fibers so that it’s more like a natural fiber or like a cotton fiber. It’s a bunch of different lengths of material, which makes it kind of hairy, but also gives us great electric, electrochemical and frictional performance.”

After this, the slivers are twisted into smaller-diameter tows or yarns, which are drawn and stretched further as they are wound onto bobbins (Fig. 4). After they are wound onto yellow bobbins, these stretch-broken oxidized carbon fiber yarns can go to one of two processes in preparation for weaving. In the first, the yarns are spun onto 6-inch-wide spools for use as weft material in weaving (Fig. 5). In the second, they are drawn and wound onto a “beamer,” a blue mandrel, about 1.5 meters in diameter, that prepares the fibers for use as warp material in weaving (Fig. 5).

Next, we leave the Textile Room and enter the Weaving Room, where AvCarb employs three Sulzer (Pego, Spain) weaving machines (Fig. 6), each about 1.5 meters wide, consuming the yarn that had been spun and wound in the Textile Room. The result is the continuous roll fabric that will become the fabric products in which AvCarb specializes.

Fig. 6. AvCarb operates three Sulzer weavers, including this one, producing woven oxidized carbon fiber fabrics. Next stop for these fabrics is carbonization. Photo Credit: CW

Leaving the Weaving Room, we follow the woven oxidized PAN into the Carbonization Room, where AvCarb applies its proprietary technology to turn the oxidized PAN fibers into carbon fibers. For this, the company employs a two-step system. The first step is a custom-made furnace about 40 meters long, through which the woven fabric is passed in a continuous process. As the fabric comes out of the furnace and is wound onto mandrels, Ebbrell says, it’s about 93% carbonized.

In the second step, the rolls of fabric are mounted on graphite racks and placed in large, custom-made, high-temperature, graphitization furnaces, which complete the carbonization process, rendering a material that is 99.9% pure carbon fiber.

From the Carbonization Room, the woven fabric will be assigned to either a friction or an electrochemical customer application. Friction fabrics are typically phenolic coated, then a final friction component will be fabricated using precision molding and cutting equipment. Electrochemical products will be supplied as is, or have functional coatings, such as PTFE, applied on a coating machine.

After coating, the electrochemical fabric travels to the Sintering Room, where its rendered hydrophobic via the sintering of PTFE on the fibers. Ebbrell explains that making the fabric hydrophobic is critical to fuel cell function as it helps keep moisture out of the cell, which improves energy production.

Following sintering, the fabric is inspected and prepared for shipment. These fabrics represent the minority of material types produced by AvCarb. Ebbrell says they can be used as GDLs, but also have application in other electrolytic products.

As important and promising the fabric is, the material format most produced by AvCarb, and the material targeted most specifically toward GDLs, is the company’s line of carbon fiber papers. As noted, the carbon fiber paper is delivered as a nonwoven substrate with binder, in which the binder has not been oxidized or carbonized. This is important, says Ebbrell, because much of AvCarb’s processing expertise, and its competitive advantage, revolves around the company’s strong heat treatment technology.

“Small changes in process can have a big influence on diffusivity of the final GDL,” Ebbrell says. “It is very important that we control all of the steps in heat treatment — not just carbonizing the fibers, but the binders as well. Everything has to be carbonized together to achieve the high purity, high thermal conductivity and electrical conductivity required.”

The first step in this manufacturing process is the wet-coating application of what Ebbrell calls a binder, but is really a carbon-based matrix system — “our secret sauce,” he notes. The use of this matrix makes the high-temperature heat-treatment process that follows akin to carbon/carbon processing, “although it’s really quite different from traditional carbon/carbon processing,” Ebbrell says.

After the binder/matrix is applied, the composite (carbon paper with binder) is first oxidized via a continuous heat treatment process. Following this, it, like the fabric, is passed through a two-stage carbonization process, eventually getting the carbon fiber nonwoven to 99.99% purity.

Adjacent to the nonwoven’s carbonization line is the heart of AvCarb’s innovation and where much of its chemical expertise is applied. The coating line (Fig. 7) is a 50-meter-long, blue and white, two-story, custom-made machine through which the nonwovens travel for application of a variety of coatings to add functionality to the carbon fibers.

Ebbrell says AvCarb passes a given roll of nonwoven through the system multiple times, depending on the coating recipe and the customer, which is dictated by how the nonwoven might be employed in the fuel cell. Most coatings are proprietary to AvCarb, but might include PTFE, for the same reason it is applied to the fabrics.

“This is the last step in making a fuel cell GDL,” Ebbrell says. Once we've made the carbon paper, it's coated with Teflon [PTFE] and the Teflon needs to be sintered to give it the right property — hydrophobic. So, if I were to get a water bottle and spray this stuff, at this end, where it's being rewound, the water would just bead up and roll off. And that property is critical to fuel cell performance.”

Where AvCarb goes from here

Back in the conference room we are rejoined by Masse, who simultaneously looks back with pride on almost 50 years of technology evolution, and ahead with hope that the fast-growing hydrogen economy will drive the company’s growth for the next 50 years. Until AvCarb was acquired in late 2021 by Arsenal Capital Partners, Masse says the company had been struggling to find the capital it needed to expand its manufacturing capabilities. The company’s unique capabilities combined with its relatively small size made it somewhat vulnerable.

“I think that’s what puts us at this exciting point right now,” Masse notes. “We have all the pieces we need to support this growing market, all of these decarbonization applications for products that fuel cells need. I think the only piece we were missing was having the resources.”

Fig. 7. Nonwoven carbon fibers — called paper — are the highest volume product at AvCarb and are targeted toward GDL applications. The paper starts as an off-the-shelf PAN nonwoven to which AvCarb adds a proprietary matrix. This is then oxidized and carbonized in a high-temperature quasi-carbon/carbon process to create the paper. Here, a roll of paper is visible in AvCarb’s coating line, where the company adds graphitic, carbon and chemical coatings in a variety of recipes to meet a variety of customer and application requirements. Photo Credit: CW

Arsenal Capital Partners, says Masse, had been eyeing AvCarb for some time as it sought a position in the hydrogen market. The decision by Arsenal to secure that position has given AvCarb the financial support it needs to expand its capacity to meet across-the-board increase in demand for its fuel cells, battery, and friction products. This makes Masse particularly excited that AvCarb is fully capable of helping meet the needs of the global decarbonization marketplace on a truly large scale.

Meeting those needs will, almost certainly, include expansion of AvCarb’s global footprint. “We want to locate near the customer,” Masse says, “and we see a lot of growth coming out of Europe, so we expect to expand there at some point. We also see growth coming out of Asia, so we have well-developed plans to add capacity there as well, if and when it is needed.”

Says Ebbrell: “Aspirationally, we want to be the number one supplier of these engineered carbon solutions for alternative energy markets as we uphold our long-standing history in ICE engines. We talked about fuel cell electrolyzers, flow batteries and other technologies that are developing in the new energy markets, and how our 50 years of experience in material science positions us for success. We always start with with a customer problem. We dig into that with them and we try to get an understanding of how a material behaves in the system, what makes it work, and how we can improve that performance. And that is the story behind virtually all of our successes.”

So, what about competitive advantage? If decarbonization and the hydrogen economy prove as dynamic as expected, what’s the barrier to entry? “How do you stop someone from coming in and just reverse engineering the whole deal?” asks Ebbrell. “What makes this tricky is the dozen-plus process steps that are involved in making our products. We use all kinds of proprietary materials and process machines in our toolkit to make the carbon paper. But if you want to reverse engineer it, at the end of the day it’s just carbon, because we've gone and carbonized everything that was in it. So we haven't really left a trace of how we've done it. That. I think, more than anything else, is how we protect our technology and our position. There isn't anybody else who can make a product like ours, and we believe we're the only one doing it this way in the world. We can scale with the industry at low risk and provide a very cost-effective and high-quality product in mass, while developing next-generation materials that will utilize the same asset base over time. How does anyone catch up with our history and plans going forward in the near-term and very expensive custom assets? Well, we don’t worry about that today. We like where we are at and look forward to supporting the customers and helping change the energy profile on our planet.”

Guy Ebbrell (left), president, and Roger Masse, CEO, in front of AvCarb’s long and complex paper-coating line. AvCarb was acquired by Arsenal Capital Partners in 2021 and has plans to expand its manufacturing capacity in Lowell, Mass., U.S. The company also wants to add facilities in Asia and Europe to meet demand for fuel cells and similar products. Photo Credit: CW

Of course, “doing it this way” has evolved over half a century — much of it guided by Masse’s long and personal experience with AvCarb. Still, he admits he’s close to retirement and might soon let the next generation take over. But for the man who started on third shift and then spent the next 47 years working nearly every job AVCO had to offer, leaving is bittersweet. I asked Masse what he would have said if, 47 years ago, someone told him that he’d one day be CEO. He pauses to think: “I would have laughed,” he says. “That would have made no sense whatsoever. Impossible to imagine.”

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreMcLaren celebrates 10 years of the McLaren P1 hybrid hypercar

Lightweight carbon fiber construction, Formula 1-inspired aerodynamics and high-performance hybrid powertrain technologies hallmark this hybrid vehicle, serve as a springboard for new race cars.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreRead Next

Plant tour: ÉireComposites, Galway, Ireland

An in-house testing business and R&D focus has led to innovative materials use and projects in a range of markets, from civil aerospace to renewable energy to marine.

Read MorePlant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More

.jpg;maxWidth=300;quality=90)