Share

Read Next

Long heritage, future-ready factory

Dowty Propellers pioneered the first composite propeller blades for turboprop aircraft in 1984 and has since manufactured more than 25,000. Opened in 2019, its 183,000-square-foot factory is optimized for state-of-the-art manufacturing. Photo Credit, all images: Dowty Propellers

Dowty Propellers (Brockworth, Gloucester, U.K.) supplies large (e.g., 4-meter-diameter) composite-bladed propellers for commercial and military turboprop aircraft, including the Dash 8-400 regional airliner manufactured by De Havilland Canada (Toronto, Ont., Canada) and the C-130J military transport produced by Lockheed Martin (Bethesda, Md., U.S.).

The four- to eight-bladed propellers for such aircraft are turned by turbine engines, which are lighter and more fuel and cost efficient than turbofan jet engines. Turboprops can also take off and land on much shorter runways, as compared to jets, but are limited to lower altitudes (below 30,000 feet) and fly at slower cruising speeds. However, for shorter range missions, as well as military and amphibious transport, turboprop aircraft are workhorses. They are also being developed for an increasing number of future zero-emission aircraft due to the higher power output per unit weight they offer compared to jet engines. They also require less maintenance because they have fewer moving parts. Dowty Propellers’ role in the manufacture of such aircraft is significant, being one of three entities — along with the engine manufacturer and aircraft OEM — that must obtain and continuously meet airworthiness certification of each aircraft type they supply.

Evolving zero-e opportunities

Lighter weight and more fuel and cost efficient than jet engines, turboprop engines have been selected for future zero-emissions aircraft concepts being developed by (top left, clockwise) Embraer, FlyZero, Airbus and Electric Aviation Group (EAG). Photo Credit: Embraer, FlyZero, Airbus and EAG.

Dowty Propellers was formed in 1937 when propeller development at Rolls-Royce (then in Derby, U.K.) and Bristol Aeroplane Co. (Filton, U.K.) was merged to form Rotol (Staverton, Gloucester, U.K.), which manufactured more than 10,000 propellers in World War II for iconic piston-engine aircraft such as the Spitfire and Hawker Hurricane. It later pioneered the first five-bladed propeller to see widespread use for the world’s first turboprop aircraft in 1947. The company began supplying commercial aircraft in 1953, became Dowty Rotol in 1960, prototyped a fiberglass propeller blade in 1968 and developed the world’s first all-composite blade in 1984 for the Saab 340 regional airliner. Dowty Propellers has manufactured more than 25,000 blades made using advanced composites and is equally well known for its integrated electronic control systems.

Acquired by GE Aviation (Cincinnati, Ohio, U.S.) in 2007, Dowty Propellers suffered a devastating fire in 2015, which destroyed its original headquarters and manufacturing facility. In 2019, it opened its new 183,000-square-foot facility about nine kilometers due south in the Gloucestershire village of Brockworth. Designed with the aid of digital tools for optimization, the new factory boasts state-of-the-art manufacturing with carbon capture for zero emissions and is powered by 100% renewable energy.

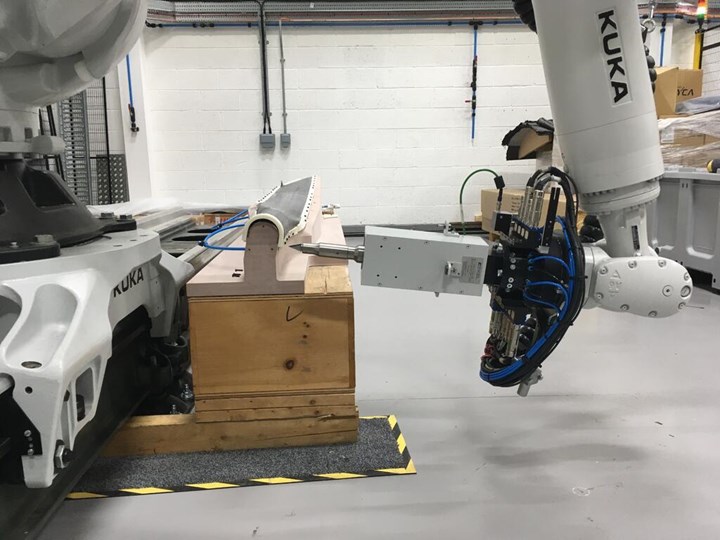

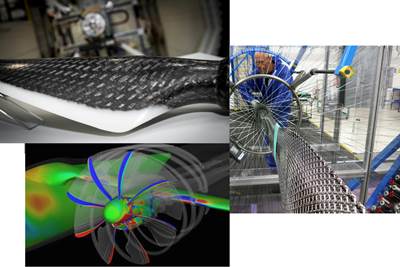

In 2021, the company announced completion of its four-year, £20 million “Digital Propulsion” program (see “DigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms”) in collaboration with the U.K.’s Advanced Manufacturing Research Centre (AMRC, Sheffield), The Manufacturing Technology Centre (MTC, Coventry) and the National Composites Centre (NCC, Bristol). Developments included triaxial braiding, thermoplastic composites and new automated composites processing options for double-digit improvements in cost and productivity, as well as new digital technologies such as improved design models, composites process simulation and digital thread/digital twin creation for each blade produced. Dowty Propellers is also building life cycle analysis (LCA) into its design process and exploring various options to improve recycling.

“We have never had a composite blade detach in flight,” says Dowty Propellers senior composites engineer, James Trevarthen, “and we want to maintain that high standard of performance and reliability — safety first, quality always. But we also need to prepare for the future.” In the past, new turboprops entering the market have been limited, notes Helen Eaton, Dowty Propellers head of marketing and communications. “But we are seeing new potential as zero-emissions aviation develops, and we’re readying ourselves for those next-generation platforms.”

Legacy markets and expertise

CW’s tour begins upstairs amongst engineering and business offices, in one of the company’s conference rooms. Here, Eaton and Trevarthen give a fuller picture of Dowty Propellers legacy and performance, as well as where it’s headed. Dowty Propellers has roughly 440 employees based at three core sites: a maintenance, repair and overhaul (MRO) facility in Sterling, Va., U.S.; a shared facility with GE Aviation for MRO in Asia Pacific in Brisbane, Australia; and its new headquarters in Brockworth, which is its only manufacturing site and also includes MRO. Eaton notes Dowty has seven propeller systems currently in production with five airframe partners.

Legacy markets. Dowty Propellers’ current markets include military transport (top) and commercial regional airliners (bottom).

“We have developed propeller technologies for four main markets,” she continues. “Our original sector was military aircraft, and now we supply a six-bladed, all-composite blade propeller for the Rolls-Royce engine on the C-130J Hercules. We also supply the C-27J Spartan made by Leonardo [Rome, Italy]. Civil regional airliners is our second main market, led by the Dash 8-400. Dowty made a key contribution in noise reduction which matches the premium experience favored by this aircraft’s market. This technology is embedded into our modeling and analysis software that allows it to be applied to any future product.”

A third market is military hovercraft that transport tanks and other heavy equipment ship to shore, powered by large fans. “The propellers for these fans require a different shape compared to aircraft and are challenging because they operate on the sea, soaking up salt spray,” explains Eaton. “We’ve learned so much that has benefited all of our propellers, especially in terms of corrosion and blade root protection. Even though we are definitely an aircraft propeller manufacturer, this experience has benefited our overall product portfolio.”

The last market is a bespoke application, the ShinMaywa US-2, which is a Japanese short takeoff and landing amphibious aircraft. Eight aircraft have been produced for the Japan Maritime Self-Defense Force, which seeks a total of 14 aircraft in operation.

In addition to its expertise in these markets, notes Eaton, “another specialism is not just the composites but also the integrated propeller controls.” In 1987, Dowty certificated the world’s first electronic constant speed and synchro-phase control system for the Fokker 50. In 1993, it received certification for the first application with electronic propeller control integrated into the engine for the Saab 2000. “Propellers have to change pitch to move in harmony with the engine,” Eaton continues. “It's obviously a very controlled relationship between the two, and what optimizes the performance of the aircraft. This relationship also creates some of the very high structural forces that our engineers must evaluate, and which make propellers so difficult. These adaptive technologies that we specialize in, however, are important because a lot of what we’re trying to achieve with composites is to create airfoil shapes that minimize noise and improve efficiency. It’s all linked together.”

“We work with all engine manufacturers,” says Eaton. “There are just a handful of substantial propeller manufacturers globally and fewer still that produce propellers in our class.” The latter include Dowty Propellers and Ratier-Figeac (Figeac, France and Conn., U.S.), which was acquired by Hamilton Sundstrand in 1908 and is now part of Collins Aerospace (Charlotte, N.C., U.S.). There are also a handful of manufacturers across the U.S. and Europe that specialize in smaller propellers for general aviation and business aircraft.

Another key expertise, says Eaton, is Dowty Propellers’ in-house testing. “This is a big area of investment and part of an iterative loop,” she explains. “We have the digital infrastructure to get test data from our development facility, which helps us make development more efficient. We then feed that data back into our digital models. It has honed our ability to reduce the development time for introducing new propellers and helps minimize entry-into-service risk. Through extensive R&D in aeroacoustics and aerodynamics, Dowty continues to drive improvement in propeller weight and noise while simultaneously advancing digitalization, automation and advanced manufacturing.”

Blade production. Dowty’s digitally optimized factory is organized into cells for efficiency and designed with extra capacity. Its composite propeller blades feature an internal spar, which transfers load through the thick, annular blade root (the right end of the blades shown here). After receiving an overbraided shell and molded using resin transfer molding (RTM), blades receive additional protective components, including a bonded nickel strip on the outboard leading edge (at left end of blades shown here) and a black rubber boot located below the nickel strip, extending to the root.

Composite blade construction

Trevarthen details the major elements of a Dowty Propellers composite blade. A carbon fiber-reinforced polymer (CFRP) spar forms the central load-bearing structure, which transfers load through the thick, annular blade root to the propeller hub. “We are very proud of the root design and construction,” he says, “which features an inner sleeve and glass fiber-reinforced wedges, all integrated with the CFRP spar to provide an extremely strong and efficient, yet robust, design. We tailor the types, quantity and angles of the fibers in the spar to achieve optimum dynamic performance, vital for the complex loads that blades experience in service. The hollow spar is filled with injected polyurethane [PU] foam — selected for a combination of structural characteristics and moldability — and then encased in a shell that resists torsion and transverse shear. The radial braiding we have developed for the shell is key for bird impact resistance. Previously, we used woven fabrics and stabilized unidirectional reinforcements placed by hand.

“We also use specialized products at the blade tip and trailing edge,” Trevarthen continues, “so that any damage here won’t propagate.” An inboard cuff uses high-density foam for additional impact resistance and a strip made from a variant of nickel prevents erosion on the leading edge. “We assemble the root as a dry preform and add various erosion and impact resistance products as well as aluminum strips for lightning strike protection [LSP],” he says. “We then resin transfer mold [RTM] the whole assembly using our bespoke injection and tooling system. We have iteratively optimized our aerospace-grade, low-temperature RTM process over 35 years. The blades then proceed through various stages of nondestructive testing [NDT] and finishing.”

R&D lab, cutting/kitting and spar preforms

Vacuum forming tool for blade spar preforms

This R&D tool uses a silicone membrane to consolidate a dry carbon fiber spar preform against a Weber nickel shell tool with integrated hot water heating, aimed to speed cycle time and reduce manual labor.

The production hall occupies most of the Dowty factory’s first floor. The tour is led by Trevarthen and Dowty manufacturing engineer, Jordan White, who started as an apprentice and has been in Dowty’s manufacturing engineering group for 10 years. “We really value apprenticeships here,” notes Trevarthen, “and have a new group starting every year.” Beginning in an open hallway that features key moments in Dowty’s history, we turn right and enter a laboratory where an R&D vacuum forming tool sits on the floor just inside. Measuring 2.5 meters long, the tool was made by Weber Manufacturing Technologies (Midland, Ont., Canada) using nickel vapor deposition technology that produces thin, lightweight tools for molding composites. It weighs 440 kilograms and features hot water heating that ramps up to 160°C in 10 minutes.

As we exit the lab, Trevarthen explains that the factory is split into cells for each stage of the blade fabrication process, including materials preparation, spar layup, foam injection/forming, skin braiding, root assembly, RTM, NDT, finishing and propeller assembly. This enables visibility into each cell and produces a more organized and efficient workspace. The first cell we see is the closed cleanroom for cutting and kitting where multiple Gerber (Tolland, Conn., U.S.) automated systems cut all dry fiber materials for use in spar preforms and glass fiber components. These plies are then kitted by technicians and delivered as needed to each process cell.

Spar preform layup. Spar preforms are hand laid using dry, bindered reinforcements in three cells, each comprising two layup tables on either side of a Virtek control station for the twin overhead laser projectors.

Next is the spar preform cell, featuring six layup stations where workers, guided by Virtek Vision (Waterloo, Ont., Canada) laser projection systems, place dry fabric plies into two female molds, each comprising half of the preform. “Before, we used heat guns to help with conforming the bindered dry fabric plies,” notes White, “but now we use handheld infrared [IR] heaters which give better quality control.”

Completed layups are vacuum bagged with a PTFE-coated glass fiber breather cloth and reusable silicone vacuum bag. They are consolidated, under vacuum, in an oven at a temperature just high enough to melt the binder on the dry plies, producing an easy-to-handle spar preform. The complete spar and blade layup will later be infiltrated with resin during RTM. The RTM cycle time sets the takt time for these spar preforming stations.

Only two of the spar preforming stations were in use during CW’s tour. “This varies depending on the build rates of our customers and the production mix on the floor,” says Trevarthen. “The new factory was designed with huge amounts of capacity. We have multiple sensitive processes in series, as well as the capability to throttle different stages in the process to make sure parts don’t sit for too long, which would increase the risk for errors and possible defects. We are constantly monitoring production floor data in order to maintain and improve process control.”

Foam injection, radial braiding, root assembly

Foam injection and forming. Foam injection stations comprise heated clamshell tools and Cannon PU foam injection systems (top).

The next cell is where a membrane is applied to the inside of spar preform halves to promote adhesion to a PU foam core, molded in-house at Dowty, which is combined with the spar preforms to form a closed shell. “This adhesion promotion is critical to ensure a good bond between the foam core and spar shell,” explains Trevarthen. Walking further, eight foam injection stations each comprise a heated, 2.5-meter-long clamshell tool on a raised platform with injection plumbing below and automated mix and dosing systems from Cannon Afros (Caronno Pertusella, Italy) at one end. A manufacturing mandrel and some of the internal root hardware are placed into the tool set, which is then closed and heated, after which the PU is injected. “A lot of process control is needed for this foam forming,” notes Trevarthen.

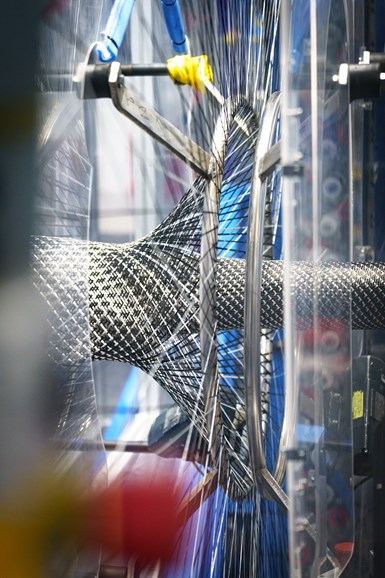

Radial braiding. Completed, foam-filled spar preforms are then passed through a radial braiding machine 5-10 times, receiving a mix of carbon and glass fibers for the propeller blade shell (bottom).

The next process stage is radial braiding of the blade shell. This station includes two Herzog (Oldenburg, Germany) radial braiding machines, which resemble large rings, each containing up to 192 fiber-filled bobbins installed at 90° to the ring’s internal circumference. Fibers from each bobbin are pulled into a central eyelet and formed into a braid at a 90° angle to the bobbins and braider ring, instead of parallel, which allows the braider to be reversed to apply plies in both directions. The machine operator at Dowty feeds a consolidated, foam-filled spar preform into one of the radial braiders. The preform is then reversed back through the braiding ring. As explained in the 2012 sidebar, “Next-generation braiding for next-gen bike,” this process is called overbraiding — where a single layer of braid is applied with each pass. This blade shell uses a mix of carbon and glass fibers, but Dowty has also looked into using thermoplastic fibers in the DigiProp program.

“This is a pretty fast process,” notes Trevarthen, “but can actually be much faster, if needed. Braiding is also very repeatable and cost and material efficient, with waste of less than 3% — whatever material is on the bobbin goes onto the blades. However, a huge amount of knowledge goes into setting it up.” Each blade shell receives five to 10 braiding passes, depending on the blade type. Just beyond the radial braiding station is the bobbin preparation room, where spools of fiber shipped to Dowty are used to wind the small bobbins for the braider, much like thread from a spool is wound onto bobbins for a household sewing machine. The room is equipped with a vacuum system to extract any carbon fiber dust generated during fiber handling. Spent bobbins are also returned here from the radial braider and put through an automated strip-off station that Dowty developed. It is now working on how to reuse these leftover fibers.

Adjacent to the bobbin room and back out in the open production area, is a cell where the thick blade root is interleaved into the blade preform after radial braiding is completed. The root is composite with a metallic outer sleeve used to interface with the propeller hub, and is quite complex, including glass fiber wedge preforms that assist with load transfer and mechanical property retention. The five stations in this area are where other specialized sections of the blade are also added, such as the woven glass fiber trailing edge, designed to be repairable, and the braided aluminized fiber LSP strips that guide electrical current to ground at the blade root. “This is an effective means of protection and is also easy to repair in the case of a lightning strike,” says Trevarthen.

RTM cell. Each of Dowty’s eight RTM stations use a horizontal action press and unique resin injection system developed in-house.

RTM, post-cure, NDT

The tour enters a large room containing eight RTM stations. Each uses a horizontal action press, developed by Dowty in collaboration with a local supplier, and includes special resin feed lines as well as a unique Dowty injection system. Operators currently rely on pressure/temperature sensors external to the mold cavity to control the injection process, but Dowty has been integrating in-mold pressure/temperature sensors by Kistler (Winterthur, Switzerland) to improve process control. “The level of data we receive from these sensors is really valuable,” notes Trevarthen.

White notes that a single injection point is used: “You do not want flow weld lines in this type of part.” The injected resin is a specially formulated two-part epoxy. This also is atypical for aerospace RTM versus the conventional use of RTM6 which is pre-mixed by the manufacturer (Hexcel, Stamford, Conn., U.S.) and shipped as a single-component resin. Regarding the reliability of mixing the two-part epoxy in-line with injection, Trevarthen explains that Dowty has used this methodology for 35 years without any issues. He also notes this process has an extremely high yield, an enviable achievement for any aerospace composites production: “The stability of our blade manufacture is such that individual process steps including RTM have yields over 95%.”

Dowty did investigate numerous options — including use of additional sensors and increased automation — for its RTM process during the DigiProp program. “The challenge is how to make improvements without messing up what we’ve gotten right and done so well for decades,” says Trevarthen. “We’ve worked with NCC to develop modeling for the whole process — which is very complex — and are using this as we step forward.”

His team is also working with Composite Integration (Saltash, U.K.) to develop a more automated injection system that will allow more flexibility — including the potential to use different materials and resin systems — without compromising quality or production yield. “We want the ability to slow or quicken injection while freeing up operators versus having to babysit gauges,” White explains. “They are experts at what they do, but it demands adjusting the equipment at the right times. The goal with the new system is to have sensors control the equipment. The operator will still be required, but freed to do higher level tasks because the equipment will be more intelligent.”

After RTM, blades are transported to one of three Genlab (Widnes, U.K.) ovens for a freestanding post-cure. Preferring not to disclose details, White notes the cycle time is quite long to manage the complex landscape of thermal expansion in the blade, including thick metal inserts and the mass-intensive root versus the PU foam at the center, which can move if heated too high or too rapidly.

The post-cured blades then proceed to the enclosed NDT cell at the rear of the production floor, which is proprietary and off-limits during the tour. This cell uses a variety of testing methods, including techniques for assuring the blade shape is precise. “We have developed a very refined NDT capability over the years,” says Trevarthen. “We can find even minute, sub-millimeter details.”

Blade finishing, propeller assembly

Propeller blade assembly/balance. After RTM, NDT and finishing, each completed blade is tested for balance, as is each finished propeller (bottom) before it is cleared for delivery.

Beyond the NDT cell is a large, enclosed shop where blade finishing begins. Here, the roots are machined with their internal features for attachment to the propeller hub using a Shark CNC mill (Next Wave CNC, Perrysburg, Ohio, U.S.). Some of the blades Dowty manufactures for hovercraft also have holes machined for bolting on erosion/impact guards.

At a subsequent station, each blade’s surface is lightly abraded to promote adhesion to high-density PU foam, which will cover the entirety of its inboard structure. This foam forms the optimal aerodynamic shape over the structural shape of the RTM component and protects primary blade structures. The blade in enclosed in a customized machine which completes automated injection of the foam.

Reliability and service. A Brockworth technician applies a new rubber deicing boot to a blade in need of service. Dowty offers global 24/7 support with 70+ field service engineers, as well as vibration monitoring to detect potential maintenance issues and MRO at all of its locations.

The next station is the Dowty paint cell, which is organized in a U-shape, accommodating two streams of painting operations. On the left, blades proceed through multiple steps to prepare the surface, apply black erosion-protection primer and complete a heated “bake” cycle. Blades then return on the right through multiple stations to complete the same steps for final paint.

After the paint cell, each blade receives a quality control check. It then moves to the cell where nickel erosion guards are applied to the outboard leading edge and blade tip. An adhesive is applied first, followed by the nickel guards. The blade is then vacuum bagged and the adhesive cured using a Heatcon (Seattle, Wash., U.S.) hot bonder to control vacuum and temperature.

The final step in this area is to apply a rubber deicing boot, produced by Dowty using an autoclave designed specifically for this task. The boot fits precisely into a rebate (recess that provides a stop) on the inboard leading edge, designed to produce a flush finished surface. The lower velocity of this part of the blade generates less centrifugal force on accumulated ice than at outboard sections, and therefore requires active deicing. The deicing boot typically overlaps the nickel erosion guard by a small amount. The boot’s length is determined by the operating RPM of the propeller.

Blades now move to one of many weight and balance stations. Here, they are attached to rotating fixtures either singly or in pairs and put through various rotation frequencies to adjust balance, much as a tire would be balanced on an automotive wheel hub. There are multiple cavities inside the blade root where a weight can be added. “This balance step is critical and affects the operation and control of the propeller,” Trevarthen explains.

The final area on the production floor is assembly, where blades are assembled into propeller hubs along with all of the control systems and ancillary components. In each of the eight propeller assembly stations, a screen overhead shows green to indicate the propeller is completed, red to signal this assembly is waiting on materials or parts and yellow to communicate further attention is needed to clear this assembly as complete. In one corner is a meeting area where key performance indicators (KPIs) are tracked and reviewed in daily meetings. “This data is gathered from multiple sources,” says Eaton, “some direct from machines and processes, some manually entered, and some from business systems. The data is collated and displayed in a centralized system that provides detail for driving operational improvements and business-level tracking.” There is also one final balance station where each multi-bladed propeller is tested on a rig before it is cleared for shipment to the customer.

Reinvention while maintaining reliability

The tour returns to the upstairs conference room to further discuss Dowty’s developments in composites. “Now that our new factory is complete, our next priority is to develop the next generation of composite propellers,” says Trevarthen. “We are building on the DigiProp program with further R&D, including testing a half-dozen demonstrators. The aviation industry has committed to zero emissions by 2050, and we’re already seeing more turboprop aircraft proposed because of their efficiency. These will push for further noise improvements, demanding even more precise and complex-shaped blades.”

The industry is also looking to produce these zero-emissions aircraft between now and 2050, which means higher volume and lower cost production systems. “Dowty has developed a suite of composites process technologies to step us away from more manual processes,” says Trevarthen. “Automated fiber placement [AFP] is not suitable for our manufacturing.” Triaxial braiding, however, is a technology explored in DigiProp that is now being refined via demonstrator programs. “We have also reduced our CFRP waste by more than 50%,” notes Trevarthen. “The next challenge is to integrate some of the automated processes we trialed for forming the foam and trimming the blade preforms.”

“To support using the automated processes developed in DigiProp, we did a lot of simulation and further developed our modeling capabilities and software tools,” he continues. “We can now optimize materials microstructure and use this for optimizing our materials selection. We have also worked with NCC and the University of Bath to complete simulations using AniForm [AniForm Engineering, Enschede, Netherlands], allowing us to convert ‘defects’ to ‘features’ in our digital models. We now have a much better understanding of the mechanisms by which defects affect part performance.”

Another key aspect of Dowty Propellers’ composites development is improved sustainability. “We are using LCA to drive our R&D strategy,” says Trevarthen. For this work, Dowty is using a range of tools, including the Eco Audit Tool in Ansys Granta EduPack (Ansys, Pittsburgh, Penn., U.S. acquired Granta design, Cambridge, U.K. in 2019). “We have identified which part of our process is the largest generator of CO2 emissions. Composite blades form 60% of the embodied CO2 in propellers. The good news is that overall, our emissions are low, due in part to our low process temperatures. We are also quantifying the amount of energy consumed at each step. RTM comprises almost 50% of our process energy usage, but the production of carbon fiber is overwhelmingly the largest energy consumption step in our products overall. We’re working with our suppliers, including Teijin [Tokyo, Japan], to minimize the environmental impact of our carbon fiber as much as possible, which they are serious about as well.”

Dowty is also open to including recycled carbon fiber in non-primary load areas of its propeller blades. “Our focus must be on getting carbon fiber back into the supply chain at the highest performance level possible,” explains Trevarthen. “We have learned a lot about how to design a part to be recyclable at its end of life, but a lot depends on what our customers want in this regard. In one development, we are looking at making the materials easier to separate — for example, keeping the carbon and glass fiber in discrete layers versus mixed hybrids during braiding. We are also working with NCC, Airbus, Leonardo, Spirit and Network Rail on a project to recover carbon fiber from aerospace scrap.”

As Dowty moves forward, will it consider producing composite propellers for UAM/AMM aircraft? “We get approached about this often,” says Eaton, “but these are much smaller propellers that are completely different from one aircraft to the next. Robustness and reliability are also not as valued because most of these aircraft have multiple, redundant units. Still, electronic control of the propellers is also key for this market, and this is definitely one of our key strengths. For now, we will stay close to our core and continue to monitor the larger zero-emissions aircraft being developed with turboprops.” However, notes Trevarthen, “DigiProp and the follow-on R&D is moving us toward more automated, faster and more flexible production. Our work with NCC to explore thermoplastic materials is our first foray into that space. We know we can truly bring value to our current customers; the issue is learning whether we can do that in these other market segments. We have technologies being developed in the background, that when some of these potential opportunities do better align, we will be ready.”

Related Content

Novel dry tape for liquid molded composites

MTorres seeks to enable next-gen aircraft and open new markets for composites with low-cost, high-permeability tapes and versatile, high-speed production lines.

Read MorePlant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreRead Next

DigiProp positions Dowty Propellers and its customers for sustainable, next-generation platforms

AMRC aids R&D program including foam thermoforming, complex braiding, thermoplastics and digital twin/thread for higher performance, lower weight with first applications in process.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More