“Irish” Composites. ÉireComposites — “Éire” meaning “Ireland” in the Irish Gaelic language — operates a 6,000-square-meter facility in Galway, Ireland. Here, the company leverages its materials and process experience and R&D focus toward commercial projects ranging from civil aviation, to wind and tidal energy and specialty equine saddles. Photo Credit, all images: CW

Many fabricators tend to focus on one specific end market area. In the case of ÉireComposites (Galway, Ireland), the focus has always been on core materials and process capabilities that can be translated to a wide range of end markets. “We’ve always had big interests in renewables and in aerospace,” Tomás Flanagan, CEO, explains.

The company that is now ÉireComposites was originally founded in 1998 by co-founders Conchúr Ó Brádaigh and P.J. Feerick. Growing out of the University of Ireland, and building on Feerick’s background in plastics and Ó Brádaigh’s academic work in composites engineering, the company began first as a composite materials testing company called Composites Testing Laboratory (CTL), which remains a subsidiary of ÉireComposites today. Less than a year after CTL was founded, ÉireComposites was started as a separate branch of the company, focused on composite parts fabrication.

“Because the company was a spinoff from the university, it’s always had a really strong research ethos,” Flanagan explains. He says the R&D focus tends to attract top engineering and manufacturing candidates — “because what we’re doing is interesting, and it’s novel, and I think that helps us to get really smart people.”

Flanagan first came on board in 2014 as R&D director. In 2018, management and investors shifted within ÉireComposites, resulting in the original co-founders and managers leaving the company and Flanagan becoming CEO. This change, plus other staff changes such as the hiring of Mark McKeigue as chief commercial officer in 2020, enabled the company to focus not only on interesting projects, but on projects that have more strategic commercial value, Flanagan says. “We’ve strengthened a lot in terms of how to run a business, and we’ve brought in some new people, and we’ve invested a bit more in factory technology and some of the software systems that run in the background,” he says.

Today, Flanagan breaks down the company’s current business by end market, with about 50% of revenue coming from aerospace work, 25% from commercial renewable energy and 25% from R&D work across various end markets, plus additional business from subsidiary CTL.

The breakdown is visually apparent during a tour of the 6,000-square-meter facility, where, at various points, aerospace components, wind blades and a range of R&D projects are all seen in different stages of manufacture.

Ultra-strong lattice cylinder demonstrator. Designed for use as the central structure on a satellite, this demonstrator cylinder, shown in small scale at ÉireComposites’ facility (bottom image) and in its full 1.5-meter-radius size at the JEC World 2022 trade show (top image), uses precise layering of overlapping thermoset composite tapes, producing a structure that easily withstood its 175-kilonewton design load during testing.

CW’s tour, led by McKeigue, begins with a number of samples from completed projects. One is a small-scale version of a 1.5-meter-radius cylinder formed as a lattice of interwoven tapes. This is a demonstrator project with ATG Innovation Ltd. (Galway, Ireland), the Irish subsidiary of space and defense technology company ATG Europe (Noordwijk, Netherlands). The goal was to build an ultra-strong, lightweight cylinder that could be used as the central structure on a satellite, with the grid-stiffened lattice design replacing traditional sandwich construction.

McKeigue says the final structure weighs only 9.8 kilograms and was easily able to withstand the design compression load of 175 kilonewtons. The key to its manufacture, he explains during the tour, is intricate layup of the tapes, which comprise Toray Advanced Composites’ (Nijverdal, Netherlands) epoxy prepreg system RS36, with Toray M55J high-modulus fibers as a unidirectional (UD) reinforcement. These tapes are manually layered one by one in a specific order to make sure they overlap in the right places. The tapes ultimately consolidate, via autoclave, to the same thickness throughout, even at the overlaps. “You’ve got continuous fibers running in each angle and rib direction,” he notes. The full 1.5-meter-diameter demonstrator was on display during the JEC World 2022 trade show in Paris, France, in May 2022.

Commercial aerospace components

McKeigue leads CW into an area of the floor where aerospace parts are manufactured and stored. Before moving into commercial aerospace parts, ÉireComposites started with R&D work for space, thanks to funding from the European Space Agency (ESA). From there, the company connected with and began making parts for Tier 1 aerospace supplier Bombardier (which became Spirit AeroSystems when acquired in 2020) in Belfast, Northern Ireland, U.K. In 2008, ÉireComposites’ first aerospace parts flew on an IAE V2500 engine.

Today, ÉireComposites manufactures parts for customers globally, and offers design, tooling manufacture and manufacturing processes such as resin transfer molding (RTM) and autoclave cure for prepreg parts. Finishing options include painting and, more recently, trimming and full assembly. The company continues to work closely with Spirit AeroSystems in Belfast, McKeigue explains, including building many tail components for Bombardier’s Global series jets, since 2014.

Commercial aerospace focus. ÉireComposites says about half of its current commercial business comes from commercial aerospace parts. Here are a few of the parts that were ready for customer delivery during CW’s tour, ranging from untrimmed pieces, to finished and painted parts to full assemblies.

As CW walked through the area, a variety of access panels, strakes, ribs and other parts could be seen in various stages of manufacture. McKeigue pointed out a rack of engine blocker doors that were stored on shelves.

Through Spirit AeroSystems, the company has a contract to build engine blocker doors for the Irkut (Moscow, Russia) MS-21 airliner, but as of the time of CW’s tour in May 2022, the project had been put on hold due to ongoing sanctions related to Russia’s invasion of Ukraine. “Who knows what the future of that program will be?” Flanagan says. Regardless of eventual delivery, though, one important aspect of the blocker doors for ÉireComposites, McKeigue explains, is that it was one of the first commercial aerospace projects where the company has been able to produce entire assemblies, including metal fittings.

Unlike the blocker doors, many of the other aerospace components seen were untrimmed — McKeigue explains that historically, all of the company’s large aerospace parts have been sold untrimmed, to be finished by the customer. In 2019, the company installed a CMS (Zogno, Italy) Ares five-axis CNC machine (6- x 2.4-meter bed), and now offers trimming services, along with capabilities for full assemblies.

Projects on display. Among the aerospace parts on display were several MS-21 engine blocker doors (pictured here), which demonstrate the company’s capabilities for full assemblies.

In the first of the company’s two cleanrooms, a Zünd (Altstätten, Switzerland) ply cutting table sits next to a table where rotor ribs are being debulked. The room operates as something of a multipurpose room, including cutting, kitting and bagging. McKeigue notes that to make more room in this space, the cutting table will soon be moved into a new cleanroom that is currently under construction.

The autoclave area is directly outside the cleanroom, allowing for easy transfer of parts directly to one of the company’s three autoclaves. Additional equipment for aerospace parts manufacture includes a small 2- x 2- x 2-meter oven, a dedicated painting booth and the CMS Ares machine, which, during the tour, was machining a tooling board trimming jig to hold in place stray light baffle space components.

In the autoclave. ÉireComposites operates three autoclaves ranging in size, pressure and temperature capacities to accommodate the requirements of parts in various end markets.

Thermoplastics and aerospace

Within aerospace, most of ÉireComposites’ current commercial projects involve thermoset composites and traditional processes, but work is also being done in the area of thermoplastic composites, especially on the R&D side of the business.

Flanagan says, “For its first 10 years, the company focused a lot on thermoplastics, so we still do quite a lot in this area. But we found that it’s [the kind of technology] that’s always coming five years into the future. I think it’s getting closer, and it’s about trying to find the places where thermoplastics work.”

Aerospace manufacture. ÉireComposites’ largest cleanroom is used for aerospace part layup and vacuum bagging prior to autoclave cure. A Zünd ply cutter (bottom photo) is also located in this room.

For example, in the aerospace industry, he notes that switching from thermoset prepregs to thermoplastics is a long, difficult leap to make, but there are other related areas in which thermoplastics can be adopted more quickly, like in ÉireComposites’ work on unmanned food delivery drones for the company Manna Drones (Dublin, Ireland). “You don’t have the same type of defined regulations as civil aerospace to contend with,” he says, “and the volumes are really different. They’re much more like automotive numbers. It’s an area where thermoplastics make sense, but thermosets will probably still be around for a long time.”

The company has also done several R&D projects with automated tape placement (ATP), also known as automatic tape laying (ATL). The company’s ATP work, Flanagan explains, has centered on laser-based in-situ consolidation of thermoplastic parts made from carbon fiber-reinforced polyetheretherketone (PEEK) tapes supplied by Suprem (Yverdon-les-Bains, Switzerland). The company’s R&D machine was mounted on a KUKA (Augsburg, Germany) robotic arm. There, the tooling was preheated electrically using external heaters, and the tapes consolidated in-situ by lasers.

“The summary of all of this work was that we made good parts, even the porosity was good, within aerospace specs. The problem is that tapes are still expensive, and the amount of heat involved uses a lot of energy. You take out the autoclave step, which is great, and you take out all the manual labor, so you can definitely see how this is the future, but there’s still work to be done,” Flanagan says. He sees potential for a variation of ATP to be useful for pressure vessel fabrication, like hydrogen storage tanks, for example, where high-volume, automated, recyclable materials and processes are needed. “It could be really good for small volumes of really large structures,” where eliminating the autoclave step is paramount, he notes.

Wind and tidal turbine blades: Thermoplastics, powder epoxy

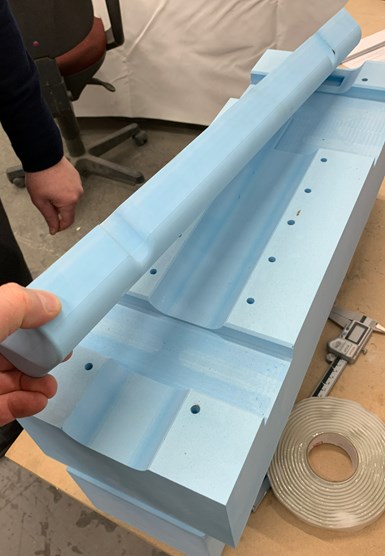

Micro wind turbine blades. ÉireComposites builds wind and tidal turbine blades up to 14 meters long, using tooling built in-house (tools shown here) and either its powder epoxy or glass fiber/polypropylene materials in a one-shot process.

Renewable energy is another large end market area for ÉireComposites, and, like aerospace, began with R&D efforts and warrants its own space in the facility. Since 2013, the company has built micro wind blades, up to 14 meters long, for wind turbine OEMs (see “Big parts? Big tooling breakthrough” for more on ÉireComposites’ work on wind blades). Several of the blades on display during the tour were made with glass fiber-reinforced polypropylene (Twintex, Owens Corning), manufactured via vacuum consolidation. Notably, this experience with Twintex wind blades led to work with this material in other end market applications, such as glass fiber/polypropylene horse saddles, which could be seen going into the company’s Langzauner (Lambrechten, Austria) press forming machine.

In the company’s quest to develop and perfect the one-shot wind turbine blade, another material option has been developed, and subsequently transferred to other end market projects: powder epoxy. McKeigue explains that for the past 10 years, the company has been using epoxy in powder form with glass fiber and manufacturing “what we call a semipreg. The material we get is like a cardboard, it’s like a prepreg, but it’s not sticky.” ÉireComposites originally built a few pilot lines to manufacture the material on site, but now outsources the material manufacture to a material supplier partner. “Powder epoxy allows us to do co-consolidated parts,” he says.

Powder epoxy for thick part sections and co-consolidated cure. “Semipreg” made from powder epoxy and glass fiber fabrics allows the company to offer a superior solution to bonded assemblies by enabling partially cured parts to be pieced together and then put through its final cure cycle as an assembly, removing the requirement for secondary bonding. Shown here are examples of materials being laid up for a marine application — including one section that measures 7 inches thick.

This semipreg material is shaped into various parts — in renewable energy applications, this means webs and skins — and then cured at a low temperature to partially solidify. At this stage, the material has not fully crosslinked and can be reversed to its original state if needed, but is solid and holds its shape. “We make two solid skins and a solid set of webs, and then put them all together, vacuum bag it and do a final cure, at which point everything polymerizes and becomes the final thermoset composite part,” McKeigue explains.

He adds, “It’s similar to preforming, but if you preform with prepreg, it’s sticky and flexible, and is just a fabric folded into a shape. In this case, the part has been heated already and is already plastic, and nearly as hard as a fully cured thermoset. You can take it off the tool and it holds its shape. It’s easier to handle.”

One of the biggest benefits to powder epoxy, he says, is that it is “really effective for thick sections.” On CW’s tour, McKeigue pointed to glass fiber-reinforced polymer shear webs up to 250 millimeters (9.8 inches) thick. “We can do thick sections really easily, and it’s really well controlled,” he says.

Another commercial project that spun out of the company’s ability to use powder epoxy to manufacture high-strength, one-shot parts is in the marine market. Wavefoil A/S (Ålesund, Norway) designs retractable bow-foils, also called wings, that attach to the front of a ship and help propel the boat. “They reduce the drag, so that you improve stability, make the journey faster, and use less fuel,” Flanagan explains. “They look like very short wind turbine blades, at 4 and 6 meters, and need to be able to handle very high loads.” Powder epoxy technology has been a key design enabler for this application, he says.

Alongside wind blades, one newer but growing market for ÉireComposites is tidal turbine blades. “We’ve probably done as much as anyone in the world on tidal turbine blades,” McKeigue says. “We’ve manufactured the largest tidal turbine blade here that’s been tested to full fatigue life.” This was a full-scale prototype blade for Orbital Marine Power’s (Edinburgh, Scotland, U.K.) O2 tidal turbine, to be installed off the coast of Scotland. ÉireComposites has also worked with the Ocean Renewable Power Co. (ORPC, Portland, Maine, U.S.) on blades for the RivGen river turbine installed in Alaska.

Specialty saddles. This press-formed glass fiber/polypropylene equine saddle is manufactured with similar technology and materials know-how as ÉireComposites’ wind blades and other products.

“And this is where there’s crossover with the R&D side of the business,” McKeigue notes. “A lot of these tidal projects began as R&D and then expand into commercial projects afterward.”

With the ORPC work, he explains that ÉireComposites started working on R&D, which turned into commercial work, which is now being done alongside continued R&D work to further innovate thetechnology. For example, in the European-funded CRIMSON project (Commercialisation of a Recyclable and Innovative Manufacturing Solution for an Optimised Novel marine turbine), ÉireComposites is working with ORPC on a version of its river turbine blades that are made from recycled carbon fiber.

Flanagan sees the tidal turbine blade part of the business growing as the market for tidal energy picks up. “First, you have to prove the technology works, and then you have to make it cheaper, to make it commercial. And that’s the point we’re at now. We think this could be a big opportunity.”

First commercial space parts

The CW tour continued next into an ultra-cleanroom, where the company’s first commercial space parts are being manufactured and then tested via a coordinate measuring machine (CMM).

ÉireComposites has been doing R&D work for ESA since 2007, McKeigue explains, mostly focusing on ATP. Through research efforts, “We were able to develop the capability, prove our competence and learn the quality systems and how ESA worked,” he says.

CNC machining. ÉireComposites acquired its five-axis CNC machine in 2019 to add trimming capabilities to its portfolio of services. The tooling board trimming jig shown in blue here will hold a cylindrical commercial satellite part during final trimming.

In 2021, the company won its first contract for commercial space parts — stray light baffles for ESA’s Altius satellite, which is scheduled for launch in 2025 and aims to monitor the Earth’s ozone layer. These baffles are essentially carbon fiber composite tubes machined with six or eight “vanes” down the length of each tube. The baffles will be attached to the sides of the satellite and serve to prevent stray light reaching the satellite’s internal optical instruments.

McKeigue explains that these parts require a lot of precision, with a tolerance as low as 20 microns. Using its heritage in both space R&D work and materials testing, ÉireComposites has done all the materials qualification, design, finite element modeling and manufacturing for the baffles.

After manufacture and testing, the baffles will be sent to OIP Sensor Systems (Oudenaarde, Belgium) to be integrated into the test satellite. Once this satellite is tested and validated, a second flight model will be built and then, ultimately, launched to space.

“It’s a new product for us. We’re hoping to develop it further to make it a commercial off-the-shelf solution for people to leverage this for other space applications,” McKeigue says. “The Altius baffle is a somewhat customized project, but with the capabilities we’ve developed working on this, we can move to a more modular product.”

Ongoing R&D: Thermoplastic drones, induction welding, Airpoxy

“All of the other workstations you’ve seen so far are stationary. But if you came back next month, this area may look completely different,” McKeigue says, as the tour enters the R&D area of the facility. Temporary workstations are set up in two rows, depending on the current projects.

During CW’s visit, one area was dedicated to assembly of a new, thermoplastic composite airframe design for Manna Drone Delivery, to replace the current thermoset composite airframe.

In the oven. The company operates four ovens — three small, high-temperature ovens for aerospace parts, and one 16-meter-long oven for wind blades and other large parts.

Another workstation focused on induction welding — specifically, optimizing and speeding up the process of using electricity to weld two carbon fiber thermoplastic panels (see “Welding thermoplastic composites” for a primer on welding). Welding, McKeigue explains, was a heavy R&D area for the company before the 2018 “rebirth,” but was set aside somewhat as the company began to refocus on more commercial projects. Now, work on induction welding has been picked back up more readily as work continues in thermoplastics, such as the Manna airframe — as well as thermoformable thermoset-based composites, like those being developed for the Horizon2020 project Airpoxy.

The overall Airpoxy project, which involves 11 partners and is led by research organization CIDETEC (Donostia-San Sebastian, Spain), aims to develop thermoformable, repairable and bondable epoxy-based composites for aerospace structures. ÉireComposites is using its expertise in thermoforming and welding to manufacture proof-of-concept parts such as a longitudinal stiffener and a leading-edge nose.

“There are a lot of people looking into welding, and there are three routes: induction, laser welding and ultrasonics. We’ve been looking at induction. I think they all make sense for different applications, and I think it’s the technology for the future,” Flanagan notes.

Composites Testing Laboratory (CTL)

The final part of the tour takes us to CTL, which operates out of the same building as ÉireComposites but is run as a separate company. Here, technicians perform materials testing for a variety of aerospace companies, including GKN Aerospace (Redditch, U.K.) and Spirit AeroSystems, as well as directly for materials suppliers. “We get testing from all over the world,” Flanagan says.

Services offered by CTL include testing for mechanical properties like fatigue, tension, compression or fire resistance, as well as a variety of environmental, process control and materials qualification testing. In the test lab, technicians can be seen preparing panels made from sample materials sent in by customers; tests are being run on several rows of machines. For example, during CW’s visit, panels were being tested for compression bending on a ZwickRoell (Ulm, Germany) test machine, for transition glass temperature (Tg) in a TA Instruments (New Castle, Del., U.S.) Q800 Dynamic Mechanical Analyzer and for fatigue in an Instron (Norwood, Mass., U.S.) machine.

The tour ends at the beginning of the facility, where the ATG Europe space demonstrator is on display, next to pictures of Bombardier’s Global aircraft, a Wavefoil and several wind turbines. Flanagan notes that the versatility in the company’s end market connections and capabilities has provided advantages the last few years, with new R&D taking off in renewables and sustainability as those topics become of more concern, as well as giving the company a variety of business options to lean into as supply chain issues, COVID-19 and Brexit cause uncertainty in certain markets.

“You can take some of the learnings from each end market and apply them to the others,” Flanagan adds. “The rigor and documentation standards in aerospace can be applied in some ways to wind energy, or we can come up with some new ways of making the other work that we do more efficient or more in line with where you see the industry headed, based on our experiences in all of these fields.”

Related Content

Cryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MorePlant tour: Middle River Aerostructure Systems, Baltimore, Md., U.S.

The historic Martin Aircraft factory is advancing digitized automation for more sustainable production of composite aerostructures.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreComposites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

Read MoreRead Next

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

Read MoreBig parts? Big tooling breakthrough

Electrically heated carbon fiber/PEEK/ceramic tooling and powdered epoxy resin system could revolutionize production of large composite aerospace structures.

Read MorePlant tour: Dowty Propellers, Gloucester, U.K.

Transforming decades of design and RTM production reliability into more sustainable, next-generation composite propellers.

Read More

.jpg;width=70;height=70;mode=crop)