Prepreg cutting system reduces waste, speeds assembly of Swiss business jet

Swiss aircraft manufacturer cites years of Zünd digital cutting systems as part of the success story for several iterations of commercial aircraft.

Source | Zünd

Thanks to carbon and glass fiber components, the PC-24 business jet, manufactured by Pilatus Aircraft AG (Stans, Switzerland), boasts a base weight of only 5.3 tons (less than 12,000 pounds), which helps it take off and land on short, unpaved or gravel runways usually reserved for turboprop planes. In fact, the PC-24 is capable of taking off on a runway as short as 890 meters (2,920 feet) and only requires 720 meters (2,362.2 feet) for landing.

Pilatus began using carbon fiber parts early on in its history of manufacturing airplanes, starting with its first carbon fiber-reinforced plastic (CFRP) and glass fiber-reinforced plastic (GFRP) components for the PC-6 Porter metal universal aircraft. The few composite components on the PC-6, which took off for the first time in 1959 and went through a production run of about 500 planes before being replaced by its successor the PC-12, were laid up by hand. PC-6 assembly, therefore, necessitated an experienced workforce and high tolerances for parts.

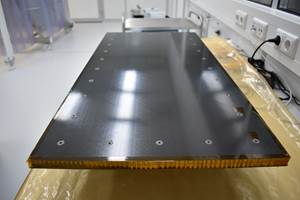

By contrast, the company’s latest aircraft type, the PC-24, consists of many parts, many of them milled at tolerances in the Mμ range. The PC-24 uses composites mainly for interior and exterior cladding. The engine casings and wingtips, too, are made of carbon fiber, as well as landing gear doors, air ducts, various pipes, covers and trailing edges on wings.

Not only does the PC-24 include more composite components than the PC-6 did in 1959, but assembly is much faster now, made possible, Pilatus says, because of advances in production technologies. Key to this are permanent reduction of costs, productivity optimization and the ability to implement modern production technologies.

Digital prepreg cutting systems are part of this trend. Pilatus has been relying on Zünd (Altstätten, Switzerland) cutting systems for years, and in 2019 added a Zünd G3 L-2500 prepreg cutting system. The G3 system single-ply cuts materials for the respective components in a largely automated process, and then labels cut pieces with an integrated inkjet module.

Source | Zünd

Pilatus processes about five rolls of prepreg per day (approximately 90 square meters), or about 90,000 square meters per year, with the rate of consumption steadily increasing as more and more CFRP and GFRP components are used on the company’s planes. Pilatus has relied on Zünd digital cutting for more than 15 years, starting with a PN-series cutter. Increased demand for carbon fiber components began to exceed capacity, which led to the addition of a Zünd G3 L-2500 in 2019. Once cutting is completed, the parts are kitted and put in cold storage until further processing. Pilatus composite structures can consist of up to 350 plies of prepreg.

Another factor in Pilatus’ success has been a focus on increasing productivity. According to Patrick Rohrer, Pilatus’ project manager of system procurement, “When dealing with cost-intensive materials such as carbon or glass fiber, material efficiency and optimization are always a concern. We are constantly working to increase utilization and thereby reduce waste — particularly since we still have few options for recycling.”

The company says it has reduced waste rates from 30% to 20%, and it cites the efficient nesting features in Zünd’s Cut Center - ZCC software as an important factor in this success. The different plies of a part are statically nested, which means a part’s individual plies are nested in the requested quantity as per order. Dynamic nesting, which is when the individual plies of parts from multiple orders are nested and combined in a single cut file, can also be used whenever it makes sense. This, Zünd says, further increases the degree of utilization of the raw material.

Related Content

Pull-wound carbon fiber poles enable lightweight, compact, rigid emergency stretcher

Based on military feedback, Epsilon Composite developed an optimized, foldable stretcher that combines telescopic pull-wound carbon fiber tubes.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreNanomaterials optimize performance of space-ready carbon fiber composite panels

A recent ESA project led by Adamant Composites aimed to mature nanomaterial-enhanced CFRP for lighter weight, more thermally and electrically conductive materials for manufacturing satellite structures.

Read MoreRecycling hydrogen tanks to produce automotive structural components

Voith Composites and partners develop recycling solutions for hydrogen storage tanks and manufacturing methods to produce automotive parts from the recycled materials.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)