Pressure vessel tank types

Pressure vessels have been classified in four categories, based on their construction. Each type has assets and liabilities.

Pressure vessels (previous to CTD’s Type V breakthrough, see Next-generation pressure vessels) have been classified in four categories, based on their construction. Each type has assets and liabilities.

Type I: All-metal construction, generally steel. Type I vessels are the least expensive, with estimated production costs of roughly $5 per liter of volume. The metalworking skills and equipment needed to produce them are widely available internationally. To their detriment, Type I vessels are the heaviest, weighing approximately 3.0 lb/L (1.4 kg/L).

Type II: Mostly steel or aluminum with a glass-fiber composite overwrap in the hoop direction. The metal vessel and composite materials share about equal structural loads. Type II vessels cost about 50 percent more to manufacture than Type I vessels, but they weigh 30 to 40 percent less.

Type III: Metal liner with full composite overwrap, generally aluminum, with a carbon fiber composite. The composite materials carry the structural loads.

Type IV: An all-composite construction featuring a polymer (typically high-density polyethylene, or HDPE) liner with carbon fiber or hybrid carbon/glass fiber composite. The composite materials carry all of the structural loads.

Type III and Type IV vessels take the weight savings even further at 0.75 lb/L to 1.0 lb/L (0.3 kg/L to 0.45 kg/L). The cost of Type III and Type IV vessels, however, is roughly two times greater than Type II vessels and 3.5 times greater than the all-metal Type I tanks.

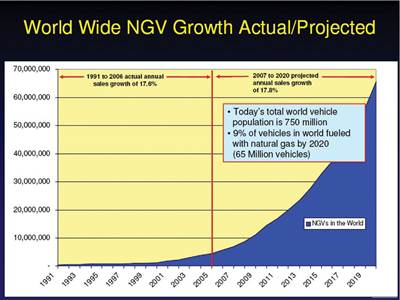

Type I pressure vessels are the most common compressed natural gas (CNG) tanks because vehicle operators in developing economies are the most common users of CNG-powered vehicles. According to recent market research (see “The outlook for composite pressure vessels," under "Editor's Picks," at top right”), Type I tanks will continue to make up the majority of the forecasted market for CNG-powered vehicles and are expected to maintain a market share of about 93 percent for the next few years. This may not sound encouraging to current or prospective manufacturers of composite pressure vessels. However, given the overall growth rate projected for future natural gas vehicle (NGV) sales, the expected 7 percent growth rate for Type II, III and IV pressure vessels represents a rapidly expanding market for composite materials, manufacturing equipment and processing technologies. Several factors point to this growth.

First, constructing pressure vessels, in whole or in part, from composites reduces fuel system and vehicle weight. On a typical transit bus or commercial truck, for example, the use of Type III and Type IV vessels easily could reduce the weight of the gas containment system by more than 1,000 lb (454 kg). This weight reduction would not only improve fuel economy, but also increase load-carrying capacity and introduce other operational benefits, making it possible for the more expensive tanks to buy their way onto vehicles.

Second, composite vessels extend the practical limit for gas containment pressures and provide better energy storage density. For many high-pressure applications — requiring cylinders rated at 5,000 psi (344.7 bar) or greater — Type III and Type IV vessels represent the most practical solution.

Third, composite materials significantly improve a pressure vessel’s corrosion resistance and overall safety. For composite vessels that incorporate carbon fiber tow as reinforcement, the excellent fatigue resistance of these fibers also extends the vessel’s service life. Carbon fiber-reinforced Type III and Type IV pressure vessels can remain in use for up to 30 years before they require replacement — twice the interval allowed for Type I and Type II vessels.

Related Content

Composite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreUpdate: THOR project for industrialized, recyclable thermoplastic composite tanks for hydrogen storage

A look into the tape/liner materials, LATW/recycling processes, design software and new equipment toward commercialization of Type 4.5 tanks.

Read MoreVertical Aerospace eVTOL prototype goes down during uncrewed test flight

The U.K. company has confirmed the Aug. 9 accident that resulted in significant aircraft damage and potential setbacks.

Read MoreHonda begins production of 2025 CR-V e:FCEV with Type 4 hydrogen tanks in U.S.

Model includes new technologies produced at Performance Manufacturing Center (PMC) in Marysville, Ohio, which is part of Honda hydrogen business strategy that includes Class 8 trucks.

Read MoreRead Next

The outlook for composite pressure vessels

Environmental and economic pressures continue to drive growth in the market for composite pressure vessels used in personal and public transportation applications.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More