Pressurized Water-based mold temperature control comes to composites

HPC editor-in-chief Jeff Sloan details recent testing that gauged the comparative efficiency of electric, oil-based and water-based mold temperature control systems.

Water-based mold temperature control units (TCUs) have been used in the thermoplastic injection molding industry for decades. They have repeatedly proven to be reliable tools for quickly and accurately ramping mold temperatures up and down to meet fast cycle time requirements.

In the composites industry, however, they have been slow to gain ground. Many manufacturers prefer to use electric cartridge heaters or oil-based mold temperature control systems. Electric cartridge heaters have appeal because they are easy to install and operate, but they don’t offer cooling capability. Critics also say they have been known to heat inconsistently. Oil-based systems are favored by molders of composites because of their familiarity, but they are slow to build temperature and, in the process, consume a great deal of energy.

Putting claims to the test

Active in the composites industry over the past couple of years, mold temperature control manufacturer SINGLE (Hochdorf, Germany and Charlotte, N.C.) has had success placing water-based mold TCUs with a few automotive composites molders — Mercedes, VW, BMW, Lamborghini and others — but SINGLE’s business development manager – composites, Kip Petrykowski, contends that the rest of the composites industry still has much to learn about fast, efficient mold temperature control. To help educate its prospective customers, SINGLE recently conducted studies to demonstrate for molders of composites the capabilities of water-based vs. oil-based and cartridge heater systems. In the process, the company amassed a significant collection of performance data. Petrykowski reports that his company’s head-to-head comparisons of water-, oil- and electric cartridge-based mold TCUs have shed considerable light on the capabilities of each technology.

Water vs. oil

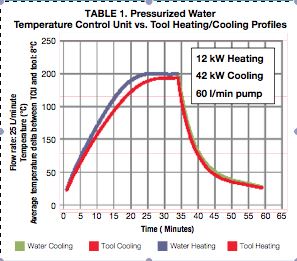

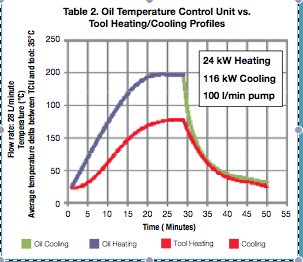

The first trial compared the performance of two SINGLE TCUs, an H.02 pressurized water system and a D.02 oil-based system. Both units had been used previously in commercial production. The mold, supplied by Weber Manufacturing Technologies Inc. (Midland, Ontario, Canada), was a single-sided, externally plumbed test tool. Petrykowski notes that the test was conducted with control units the company happened to have in stock. For that reason, the oil unit had twice the heating capacity, 2.8 times the cooling capacity and 1.6 times the maximum rated flow of the pressurized-water unit. Also, the inside diameters of the oil unit’s heating and cooling inlets were 1.8 times larger than those of the water unit, giving the oil unit a significant advantage in terms of potential flow rates through the mold.

The results of the tests (Tables 1 & 2) indicate that the flow rate through the tool was greater with the oil unit, something Petrykowski says would be expected, with a flow of 100 liters/hr (2.4 gal/hr) compared to 60 liters/hr (15.9 gal/hr) for the water unit. The temperature differentials for incoming and outgoing fluid in the oil unit averaged 3.75°C. The water unit averaged 2°C. Both numbers are within the range of typical values for tools flowing at optimum rates. Based on this data, SINGLE reports it is unlikely that either system’s heat transfer efficiency would benefit from additional flow. Not charted in the study was the fact that the oil unit averaged a 2.75°C temperature differential across the tool face, while the water unit averaged less than 1°C.

However, even with twice the heating capacity (24 kW vs. 12 kW), 2.8 times the cooling capacity (116 kW vs. 41 kW) and 1.6 times the flow rate (100 liters/min vs. 60 liters/min), the oil unit was unable to heat or cool the mold faster than the water unit. The oil unit also consumed 69 percent more electricity. The limitation of greatest concern for the oil unit, says Petrykowski, is the large temperature difference between the TCU and the mold surface. The temperature of the mold surface should, ideally, closely match the temperature control set point to minimize uncertainty about mold temperature parameters.

Water vs. electric cartridge heater

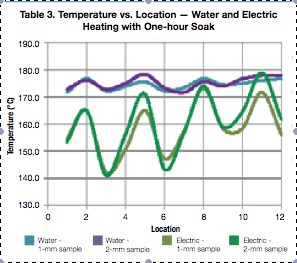

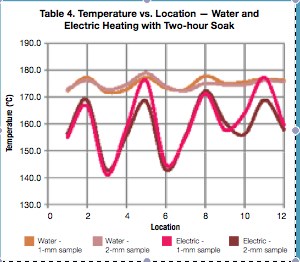

SINGLE also compared a pressurized water TCU with an electric cartridge unit. The mold here was a two-sided 18 kg/39.7 lb test mold. During the test, mold temperature readings for both units were taken at one-minute intervals, using a surface pyrometer placed at the center of each mold surface. The temperature of the water-based units’ outgoing and returning fluid as it circulated through the mold and the energy it consumed were read directly from the controllers on the unit.

The mold temperatures during the electric cartridge test were controlled by comparison of input received from a thermocouple placed in the mold to a temperature set point on the unit’s controller. The test mold, says Petrykowski, was not optimized for water flow and, therefore, allowed a flow of only 9 liters/min. Further, the water-based TCU was the smallest SINGLE unit available and was rated at only 6 kW — one-fifth the rated capacity of the electric cartridge unit. The material used to mold the part was a fiber-reinforced polyetheretherketone (PEEK).

Tables 3 & 4 show the results from the pressurized water vs. electric cartridge tests. The readings, notes Petrykowski, indicate that the water-heated mold cycles were more consistent. The average temperatures measured at the same location on the mold surfaces during the two-hour test period were 1.94°C for the pressurized water TCU and 6.7°C for the electric cartridge system.

Another important distinction, Petrykowski notes, was the difference in temperature over the length of a part. The average temperature differential across one part at the same moment was 21.0°C during the electric cartridge trial; the average differential for the pressurized water trial was only 2.7°C.

A temperature differential as large as that recorded over the length of one part in the mold that was heated by the electric cartridge could result in crystallinity variations within the part, Petrykowski contends. This, in turn, could result in shrinkage differences throughout the part, producing molded-in stress that could manifest in part warpage, creep and physical property differences within the same part.

To determine if the parts produced with each TCU attained acceptable levels of crystallinity, they were analyzed via differential scanning calorimetry (DSC) to determine the percentage of crystallinity. The DSC results demonstrated that the parts produced in the water-heated mold had consistent and acceptable crystallinity along their lengths. For the parts produced in the electric cartridge-heated mold, however, different crystallinity percentages were measured along the test parts’ lengths.

These new data, says SINGLE, clearly demonstrate that pressurized-water TCUs can not only meet the needs of composites manufacturers but also can do so efficiently and economically. This capability could prove beneficial as the advanced composites manufacturing community continues to evolve toward more fast-cycle, rapid-cure, out-of-autoclave (OOA) fabrication processes.

Related Content

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MorePlataine unveils AI-based autoclave scheduling optimization tool

The Autoclave Scheduler is designed to increase autoclave throughput, save operational costs and energy, and contribute to sustainable composite manufacturing.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreVIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpg;maxWidth=300;quality=90)