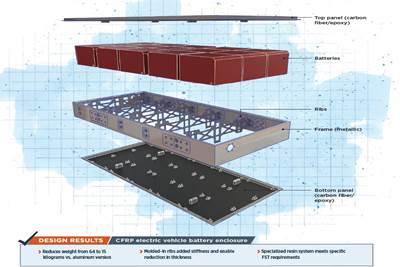

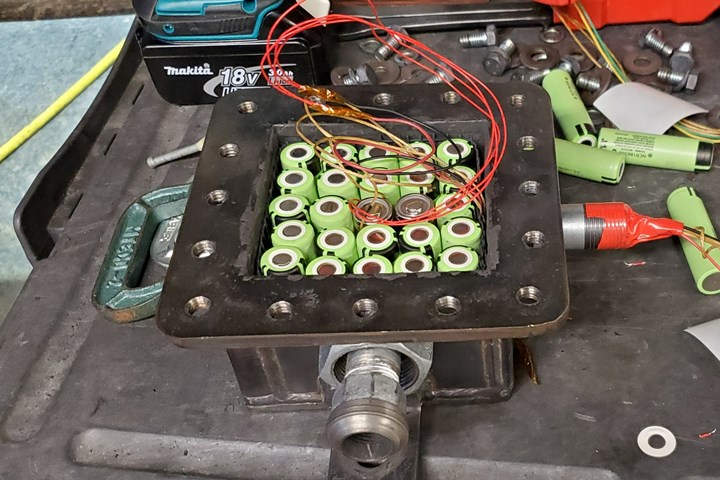

Hyundai-Kia America Technical Center (HATCI) and Forward Engineering North America LLC recently worked together to design a new method of testing thermal runaway performance in composite materials for electric vehicle (EV) battery enclosures. The test box, pictured here prior to setup with a test material, uses resistive heaters and pressure to simulate a real-world battery enclosure environment. Photo Credit, all images: HATCI and Forward Engineering

Protective battery enclosures and covers for battery electric vehicles (BEV) are often considered to be one of the biggest potential growth areas for composite materials within the automotive market. BEV batteries are larger and heavier than batteries on internal combustion engine (ICE) vehicles, and need strong protection against potential issues like leakage or thermal runaway, inviting solutions in lightweight composite materials that have been adapted for fire resistance and other desired properties.

There are many materials suppliers, composites fabricators and automotive OEMs working in this area, but according to Amanda Nummy, senior polymer materials engineer at Hyundai-Kia America Technical Center (HATCI, Superior Township, Mich., U.S.), the field is still new enough that adequate screening methods for battery enclosure materials do not yet exist.

Specifically, Nummy and her team realized while evaluating material options for potential Hyundai-Kia vehicles, that none of the current material-level testing standards were capable of adequately simulating and evaluating thermal runaway performance — the ability of a battery enclosure material to protect against potentially dangerous heat and pressure escaping from a malfunctioning battery into the rest of the vehicle.

During a presentation at the Society of Plastics Engineers’ (SPE) Automotive Composite Conference and Exposition (ACCE) in November 2021, Nummy explained that common global standards such as UL 2580, GB 38031-2020, ECE R100 (Rev2) and GTR 20 focus on battery pack level performance, leaving a gap at the material screening level.

There are some basic torch test methods that exist to evaluate material performance in the event of a fire, but Nummy says these do not sufficiently reflect real-world exposure during a thermal runaway event, and they do not simulate the high pressures or loads that battery enclosures exist under. Given these limitations, in 2019 Nummy and her team decided to develop their own test protocol.

Developing a thermal runaway material screening program

The HATCI team began working with Forward Engineering North America LLC (Royal Oak, Mich., U.S.), a development and consulting company specializing in composite automotive solutions. Between 2019 and 2021, the two companies trialed a range of prototype test systems, aiming to create a simple, repeatable and reliable material-level screening process representing real-world thermal runaway conditions. The process was intended to enable materials suppliers to develop more capable materials, and automotive OEMs the ability to make smart materials choices early in the design process.

Pictured here, the test panel is bolted to the top of the test box for testing.

According to Adam Halsband, managing director of Forward Engineering North America, Forward Engineering aided in designing the test itself, engaged key stakeholders in the industry, communicated with standards organization UL (Northbrook, Ill., U.S.) on HATCI’s behalf and provided technical engineering support along the way.

The method tests for three key factors: pressure, temperature and abrasion — all of which a battery enclosure needs to be able to endure in the case of a thermal runaway event. The test method that the partners ultimately developed takes place within a small, square steel box designed to contain a 5 x 5-inch array of 18650 cylindrical lithium-ion battery cells. A 2-millimeter-thick flat test panel is then bolted to the top of the box above the batteries. During testing, heat is introduced by two resistive heaters placed on the sides of the central battery cells, at a rate of 6°C (10.8°F) per minute, to initiate the thermal runaway event in a controlled fashion. As Nummy explains, a series of tests using different restrictor plates emulate thermal runaway conditions at different targeted pressures (250 kPa, 500 kPaand 1 Mpa) which can be used to understand a test material’s behavior most effectively.

Thermocouples are used to measure temperature in the enclosure above and beneath the sample, and a pressure transducer monitors pressure within the enclosure. A high-definition video camera with a microphone monitors the test and provides insights into material response, and allows the operators to see whether the sample ignited or generated smoke. A high-frequency data acquisition system collects data from the initiation of the thermal runaway event through at least five minutes after the event.

The development work allowed Nummy and her team to gain new insights and a more nuanced understanding of material performance than before, she says. “It was particularly interesting to see the unique and different ways in which materials respond to the combined forces of a thermal runaway event” besides ultimate failure, she notes.

The HATCI/Forward Engineering protocol uses resistive heaters, as opposed to open flames, to see how materials respond to real-world heating and pressure situations. Ultimate failure or yield is evidenced by the emission of flames and/or plasma from the top of the specimen, shown here.

So far, HATCI and Forward Engineering have tested a variety of materials, including discontinuous and continuous fibers, thermosets and thermoplastics and hybrid combinations of metal and composites.

By 2021, the partners had built a full-scale test system and continued repeating the process to validate the results.

UL standard and continuing development

Ultimately, HATCI and Forward Engineering’s goal is to make this protocol available for use by any material supplier or OEM, helping to democratize EV component safety beyond only Hyundai-Kia vehicles. To this end, HATCI and Forward Engineering worked with UL, and the protocol was made publicly available as UL standard 2596 as of Jan. 27, 2022.

Nummy notes that more work continues to be done to build data on more material types. The team is also considering the possibility to add capabilities to account for parameters such as additional pressure levels, cell formatsand design components in future versions of the test.

Halsband and Nummy both see a lot of potential for this test going forward, but Nummy acknowledges that there has been a lot of skepticism from the industry at first, namely that a new test wasn’t necessary. “We’ve proven that this is a repeatable, more accurate method of simulating real-world battery conditions,” she says. “Not to replace the existing torch testing completely, but to add to it.”

Related Content

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreOptimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreRead Next

Designing a versatile, multi-material EV battery enclosure

Continental Structural Plastics has developed one-piece, compression-molded composite covers, an innovative fastening system and a range of material options to meet OEM needs.

Read MoreEV battery enclosure inspires material, process innovations

High unit volume and low weight requirements for electric bus battery enclosures fueled development of TRB Lightweight Structures’ specialized epoxy system and automated composites production line.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More

.jpg;width=70;height=70;mode=crop)

.jpg;maxWidth=300;quality=90)