Quasi-isotropic, symmetrical fabric for tooling

Well-known in structural applications, this symmetric, balanced and quasi-isotropic fabric offers savings and opens opportunities in composites tooling.

This blog comes from my discussions with Steve Savoie, a manufacturing and tooling engineer who spoke at last year’s International Boatbuilders Exhibition (IBEX). Steve has a background in both aerospace and marine composites, and specializes in process development, tooling design and equipment utilization. For example, his session at IBEX discussed temporary oven design and cheap ways to set up aerospace-quality data loggers and temperature control systems (watch for a blog on that coming soon). We were discussing a project using A&P Technology’s (Cincinnati, OH, US) QISO material, and he commented what a great material it is for tooling, but that a lot of people don’t seem aware of it for that end use. Not being an expert on tooling myself, I asked Steve to explain what QISO offers for composite tooling and why.

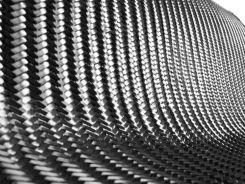

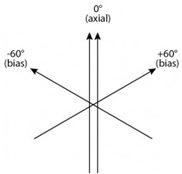

QISO was introduced by A&P several years ago. Its weave pattern features 0°/±60° carbon fiber tows braided to yield a single layer of fabric that is balanced, symmetrical and quasi-isotropic. This offers real benefits for layup of complex tooling geometry. The bias yarns are two over, two under, alternating over and under the axial yarns with equal amounts of material by weight in each direction. A&P also notes that in testing, QISO has demonstrated reduced interlaminar stresses vs. more traditional laminates (e.g., 0°/±45°/90°) because all QISO plies feature the same architecture — i.e., you don’t have a large stiffness in the 0°, which then drops off in the ±45° directions.

QISO carbon fiber fabric is balanced, symmetric and quasi-isotropic, all in one layer.

SOURCE: A&P Technology.

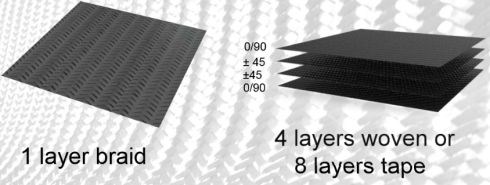

According to Savoie, QISO enables material savings by not having to cut and orient each individual ply to create a quasi-isotropic layup, as is typically done with conventional weaves. Since the braided fabric is quasi-isotropic itself, this step is removed from the fabricator. This is significant when one considers the typical waste involved when cutting fabric on a 45° angle for a typical eight-ply layup for quasi-isotropic tooling skins.

QISO enables multi-ply tooling layups with less labor and waste.

SOURCE: A&P Technology.

Being freed from the typical eight-ply tooling laminate also opens the possibility of unique layups such as six- or even nine-ply constructions, for example. By tailoring the mold tool sheet thickness (and cost), the tooling designer can place the fabric only where it is needed to maintain tool stiffness and geometry.

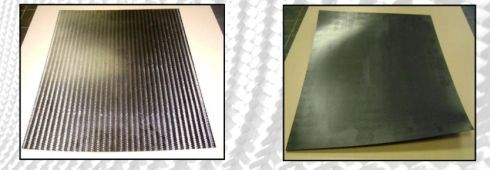

Another noteworthy attribute of QISO quasi-isotropic fabric is that it is a balanced, symmetric weave, which obviates the need to ensure the weave architecture is symmetrical across the neutral axis of the laminate. Better said, the cured tooling will not “potato chip”.

Editor’s note: A balanced fabric or laminate has equal numbers of plus- and minus-angled plies. A symmetric fabric or laminate has ply orientations that are symmetric about the mid-plane (neutral axis). Quoting from Abaris Training’s textbook on advanced composite fabrication and repair: “Laminate symmetry is necessary to maintain dimensional stability through processing.”

Savoie’s example of potato chipping is when a single ply of an asymmetric weave such as a five-harness satin is processed through an elevated cure cycle. Upon returning to room temperature the thermal stress of the matrix typically cups opposing points on one axis up and the perpendicular axis down. To counteract this effect, one typically has to make sure the weave architecture is layed up to produce symmetry about the neutral axis. This process is often termed “paper up, paper down,” which refers to the release paper side of prepregged fabric, and making sure asymmetric fabrics are flipped upside down on the other side of the mid-plane. This is not necessary with QISO because the fabric itself is symmetric.

Symmetric QISO Asymmetric woven

Because QISO is symmetric, it alleviates issues with warping due to thermal stresses.

SOURCE: A&P Technology.

QISO also provides a cost-effective solution for backing structure (egg crate) on elevated-cure composite tooling. Savoie says the material lays down fast right off the roll, and the heavy weight version bulks up quickly. In addition, he says its price per pound is very attractive. The width of the sheet is easily augmented with an additional strip of fabric, making sure to stagger joint placement for additional plies. Similar to the tooling shell, the backing structure laminate is symmetric and quasi-isotropic so that adding or reducing the thickness of the sheet is as easy as adding more plies or laying up less. QISO is offered in a variety of standard widths including 36, 52 and 59 inches and also in a range of standard areal weights including 272 g/m2 (gsm), 532 gsm and 1150 gsm. Fabric widths and weights can also be customized.

As with any other new fabric to a shop, Savoie advises doing an infusion rate study with the tooling resin selected for the application. These infused flat sheets (typically 0.25-inch thick) are well suited for waterjet cutting, which makes them an economical alternative to purchasing processed sheet stock. A&P is also working with TenCate Advanced Composites (Morgan Hill, CA, US) to offer QISO fabrics as standard prepregs.

While the focus here is on tooling applications, QISO has and continues to be used for a variety of structural composites (see Editor’s Picks at right).

Steve Savoie consults in the greater New England area and can be reached at CBNFBR@gwi.net.

Related Content

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRecycling end-of-life composite parts: New methods, markets

From infrastructure solutions to consumer products, Polish recycler Anmet and Netherlands-based researchers are developing new methods for repurposing wind turbine blades and other composite parts.

Read MoreThe lessons behind OceanGate

Carbon fiber composites faced much criticism in the wake of the OceanGate submersible accident. CW’s publisher Jeff Sloan explains that it’s not that simple.

Read MoreCryo-compressed hydrogen, the best solution for storage and refueling stations?

Cryomotive’s CRYOGAS solution claims the highest storage density, lowest refueling cost and widest operating range without H2 losses while using one-fifth the carbon fiber required in compressed gas tanks.

Read MoreRead Next

New aerocomposites niche: Helicopter transmission gears?

A NASA study shows that steel/composite hybrid gears save significant weight, and could mitigate vibration-related noise.

Read MoreTriaxial fabric wrap saves critical highway pier

The Department of Civil Engineering at the University of Kentucky (Lexington, Ky.), and sister research group the Kentucky Transportation Cabinet, recently completed the first bridge pier repair demonstration project to use triaxial carbon fabric.

Read MoreBack-country boating: Carbon fiber Adirondack pack canoe

Placid Boatworks (Lake Placid, NY, US) makes modern composite versions of classic, but relatively heavy, Adirondack pack canoes, using vacuum-infused carbon fiber. Here's how.

Read More