Rapid Manufacturing, Part I: The Technologies

An outgrowth of rapid prototyping, tool-free additive fabrication is shortening product development cycles for manufacturers of smaller, limited-run composite parts.

Ever shorter lead times from design to production are a fact of life for manufacturers. Only 10 years ago, for example, the auto industry standard for getting a new car model through engineering and into assembly was 48 months. Today, it's half that. Given the need to fast-track more fuel-efficient vehicles to market to assuage the widespread public concern about rising fuel prices, additional compression is in the cards. Similar trends can be seen in many other industries. There is also pressure to lower costs, brought on, in part, by manufacturers with access to low-cost labor in the world's developing economies. Moreover, molders are approaching the practical limits of speed in their molding processes. Therefore, the focus has sharpened on one of the slower and most costly pieces of the manufacturing puzzle — tooling.

Strategies for reducing the cost and shortening the fabrication cycle for tooling abound. New materials and innovative technologies are regularly introduced toward that end and have been chronicled periodically in the pages of this magazine. One initiative, however, has as its goal to significantly reduce the impact of tooling on product cost by eliminating it, at least in the product development cycle. The concept of rapid prototyping (RP) actually was introduced more than 20 years ago. RP describes a collection of similar but separately developed additive fabrication technologies, that is, automated processes that assemble a three-dimensional object from a series of nominally two-dimensional, cross-sectional layers of specialized materials.

THE BASICS OF ADDITIVE BUILDING

All additive fabrication begins with a CAD drawing. CAD software packages generally tend to represent 3-D objects more accurately than wire-frame modelers. The CAD file is then converted into an STL file (for stereolithography, the first RP technique). The STL format represents a three-dimensional surface as an assembly of planar triangles. Because STL files rely on planar elements, they cannot represent curved surfaces exactly. Designers achieve a good approximation of curves by reducing the size and increasing the number of triangles, which, in turn, results in a bigger file size. Larger files require more time to build, which can defeat the purpose of RP, so designers balance accuracy with practical concerns when producing the file. This trade-off is universal, regardless of the RP process selected.

When the CAD file is created, proprietary software is used to "slice" the 3-D CAD image into very thin 2-D cross-sections. These flat 2-D slices form the patterns for successive build layers. This layer data is used to instruct the additive fabrication machinery as it builds the 3-D model by "stacking" the 2-D slices.

Today, there are six additive fabrication technologies in use: Stereolithography, Fused Deposition Modeling, Selective Laser Sintering, Laminated Object Manufacturing, 3D Ink Jet Printing and Solid Ground Curing. Of these, only three, Stereolithography, Fused Deposition Modeling and Selective Laser Sintering, are widely used in the composites industry at present. This is partly because systems based on these RP technologies are more commercially dominant, but also because a number of composite materials (or composite applications using noncomposite resins) have been developed for use with these systems.

Stereolithography (SLA), patented in 1986, was the first fully commercial rapid prototyping technology and is still the most widely used. In general, SLA is preferred when either a good surface finish or very precise modeling is required. In the SLA process, the part model is built on a platform positioned just below the surface in a vat of liquid photocurable polymer, usually an epoxy or acrylate resin. A low-powered UV laser, programmed with the previously created CAD slice data, traces out the first layer of the part with its highly focused UV light beam, scanning and curing the resin within the boundaries of the slice outline until the entire area within the slice cross-section is solidified. An elevator then incrementally lowers the platform into the liquid polymer to a depth equal to the slice thickness, and a sweeper recoats the solidified layer with liquid polymer. The laser then traces out a second layer on top of the first. The process is repeated until the part is complete. Depending on the geometry of the part, mechanical supports may need to be built around the part during the build to contain the liquid. After removal from the vat, supports are removed, and the part is placed in an ultraviolet oven for additional curing.

Typical tolerances for an SLA part with an edge ranging in length to 200 mm/8 inches is ±0.1 mm (±0.004 inch) and about ±0.4 mm (±0.016 inches) for a part with an edge up 500 mm (19 inches) long.

Since 1988, 3D Systems (Valencia, Calif.) has been the sole manufacturer of SLA RP machines. The company currently offers a line of five machines, including the Viper HA SLA System, the Viper SLA System, the SLA 5000 System, the SLA 7000 System and the Viper Pro SLA. Build envelopes, speed and other machine characteristics vary with each machine. The company's new-generation large-format machine, the Viper Pro, is capable of building a single part as large as 1,500 mm by 750 mm by 500 mm (59 inches by 29.5 inches by 19.7 inches) or producing multiple smaller parts, with the same or different build configurations. The company says the system is capable of achieving a surface finish "normally associated with CNC machining."

Fused Deposition Modeling (FDM) was commercialized in 1990 when Stratasys Inc. (Eden Prairie, Minn.) built the first FDM machine. The second most widely used RP process after stereolithography, FDM builds parts out of ABS, polycarbonate and other resins noted for toughness. It is often chosen when durability of a part is paramount. As with other RP techniques, FDM works on an additive principle of building a 3-D object one layer at a time. A plastic filament is unwound from a coil, supplying material to a heated extrusion nozzle, which controls the flow. The nozzle is mounted to a mechanical stage that can be moved horizontally and/or vertically. The nozzle moves over the stage, which is coated with a support material, depositing a thin bead of extruded plastic. For ABS, the thickness of that layer is typically 0.010 inch/0.25 mm, which roughly defines the tolerance one can expect to hold for a part made with FDM. The extruded plastic bonds with the previously extruded layer then hardens immediately. The entire system is contained in a chamber held at a temperature just below the melting point of the plastic. No postprocessing is required after the part is removed from the chamber. In addition to ABS and polycarbonate, FDM machines also can build 3-D objects from certain waxes and polyphenylsulfone materials. The finish of parts produced by FDM has improved over the years, but it isn't quite on par with SLA.

Stratasys is the sole manufacturer of FDM machines in North America, although several Asian companies are licensed to build FDM machines for sales in Asia. The Stratasys line includes the FDM 200mc, 360mc, 400mc and 900mc machines. The FDM 900mc is the latest model and comes with a 36 inch by 24 inch by 36 inch (914 mm by 610 mm by 913 mm) build envelope. Based on a new platform, it is distinct from previous FDM systems, providing much improved accuracy, says the company. The machine comes with Insight software, which imports STL files, automatically creates part slices and generates support structure data and material extrusion paths.

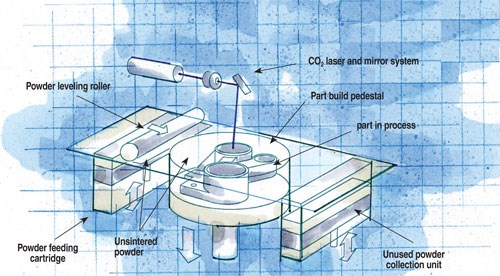

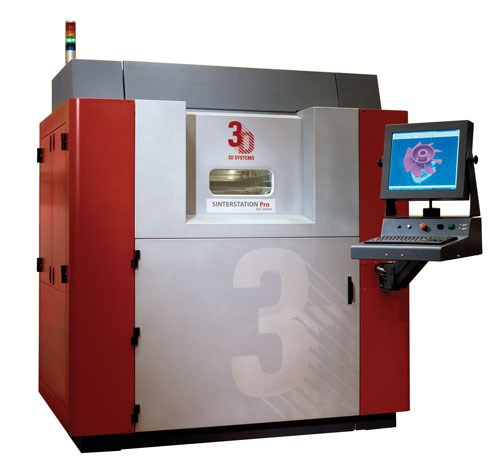

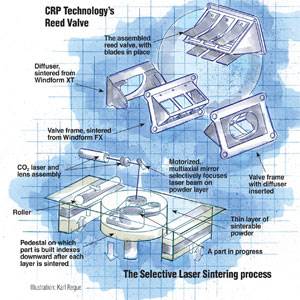

Selective Laser Sintering (SLS) was developed in the late 1980s by Austin, Texas-based DTM Corporation, purchased by 3D Systems in 2001. In a method similar to that employed in stereolithography, SLS uses the heat of a CO2 laser to process a variety of materials manufactured especially for the process in powdered form, as op-posed to the liquid polymer used in SLA. These materials include nylon, glass fiber- or carbon fiber-filled nylon, elastomers, waxes, ceramics and certain metals. The process takes place within an enclosed, modular unit about the size of a print shop photocopy machine. Inside, the CO2 laser and a mirrored reflector system is mounted over a build table or pedestal, which supports the part. A roller distributes a thin layer of the powdered material over the pedestal surface, and then the mirror system directs the laser beam onto the powder layer. As the beam scans back and forth across the material, the laser turns on and off, selectively sintering the powder (heating the powder grains to melt or fusion temperature) in a pattern identical in size and shape to the cross-sectional slice derived from the converted CAD file. The pedestal is then lowered the distance of the layer thickness, another layer of powder is rolled over the cooled and now solidified first layer, and the sintering process is repeated, bonding the second layer to the first. A part is built up in this way, in layers of 0.003 inch to 0.006 inch (0.08 mm to 0.15 mm) thickness, until the part is complete. The typical tolerances for parts made on SLS machines range from ±0.1 mm (±0.004 inch) for a part with 100 mm (3.9 inch) edge, to ±0.2 mm (±0.007 inch) for a part with a 200 mm (7.8 inches) edge, and ±0.75 mm (±0.030 inch) for a part with a 500 mm (19.6 inches) edge.

The primary benefit of SLS is the produced part's durability and the fact that SLS users may choose from the widest range of engineering-grade materials available in the RP industry. Also, unlike stereolithography, SLS does not require support structures during the forming process because the unused powdered material that surrounds the part provides adequate support. Moreover, SLS requires no postcuring, and parts usually can be machined, painted and/or bonded when they leave the machine. The main disadvantages of SLS are relatively low accuracy/repeatability, poor surface finish and comparatively high porosity. The density of nylon parts made with SLS, for example, is only 87 to 93 percent that of an injection molded part.

3D Systems' line of SLS machines includes the Sinterstation Pro SLS 140 and 230 models and the Sinterstation HiQ. The maximum build volume of the HiQ's midrange model is approximately 15 inches by 13 inches by 18 inches (381 mm by 330 mm by 457 mm), while the large-format version can make parts as big as 21 inches by 21 inches by 29 inches (533 mm by 533 mm by 737 mm). The Sinterstation Pro SLS 230 offers the largest build volume, 22 inches by 22 inches by 30 inches (550 mm by 550 mm by 750 mm), while the Sinterstation HiQ is equipped with Beam Delivery Optics and a more powerful laser that reportedly nearly doubles vertical build speed.

FROM RAPID PROTOTYPING TO RAPID MANUFACTURING

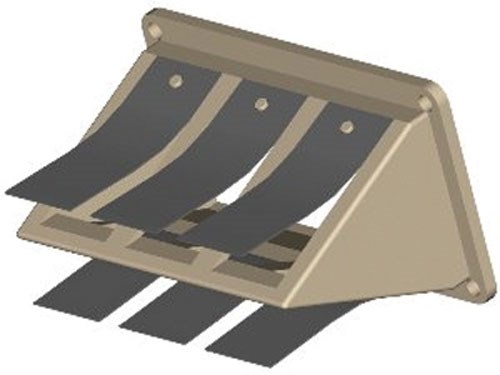

As the term "rapid prototyping" implies, these additive technologies were originally intended to and still do enable part designers and engineers to bypass the need for prototype tooling. Using RP, a designer can make a prototype part or parts in days or even hours to evaluate form, fit and mating characteristics and, in some cases, to serve as test articles, such as those for wind tunnel evaluation of part aerodynamics. More recently, however, RP users, often in league with those who supply the RP technologies, have ventured beyond the classic RP mandate. Up until a few years ago, the RP technologies profiled above were used almost exclusively to make prototypes and, in some cases, build tools for highly specialized, low-volume production runs. Under ever-mounting pressure to decrease product development times, however, designers realized that there is the potential to use additive fabrication systems to make production parts. In a paper presented at 3D Systems' Users Conference in April, for example, Dr. Ing. Livia Cevolini of CRP Technology Srl (Modena, Italy) reported that Ilmor Engineering, Penske Racing, Lamborghini and other motor sport firms are now pushing the edge of traditional rapid prototyping, with the help of new materials and equipment, to make composite production parts (see "Learn More," at right). BMW engineer Günter Schmid (Munich Germany) says that Fused Deposition Modeling "is taking on increasing importance as an alternative manufacturing method for components made in small numbers." The company's plant in Regensburg, Germany regularly uses FDM to build lightweight, handheld assembly aids and devices for automobile assembly and testing devices with enhanced ergonomics for its assembly line technicians. According to one industry source, The Boeing Co. (Seattle, Wash.) is using a modified SLS platform to make air conditioning conduits and other parts from glass-filled nylon.

RP industry consultant and analyst Terry Wohlers (Wohlers Associates, Fort Collins, Colo.) says that users of additive fabrication technology now derive about 12 percent of their revenues from some type of manufacturing, compared with just 3.7 percent in 2003. That's about $132 million for manufactured parts.

Although the portion of that figure that can be attributed to composite manufacturers is not known and is likely to be relatively small at this point, the trend toward rapid manufacturing appears to have special relevance for the composites industry. Not only have equipment manufacturers, RP service bureaus and in some cases end-users themselves developed new composite materials compatible with the three additive fabrication processes previously noted, but the low production volumes that characterize some segments of the composites industry make tool-free manufacturing or, in some cases, rapid manufacturing of tools, a viable option for limited-run or specialized niche parts. As additive fabrication segues from RP to rapid manufacturing (RM), its perception as an exotic and specialized technology is fading.

"The term rapid prototyping really mischaracterizes what we're doing with this technology," claims Ron Jones, president and CEO of Dynastrosi Laboratories Inc. (Bowling Green, Ky.). Indeed, rapid manufacturing, as young as it is, already has acquired several inventive descriptors, including solid free-form manufacturing, e-Manufacturing and direct digital manufacturing.

While it is far too early to declare this phenomenon revolutionary, additive fabrication is making inroads into composites manufacturing (see "Rapid Manufacturing, Part II," under "Editor's Picks" at right). Each of the technologies previously discussed are proving capable — when conditions are favorable — of offering an affordable alternative to once costly and time-consuming commercialization cycles. To be sure, favorable conditions are likely to include relatively small part size. Additive fabrication machine build envelopes currently impose physical limits on part size while the speeds at which current laser and extrusion technologies are able to operate almost certainly exclude yacht hulls, for example, as viable RM candidates any time in the foreseeable future. Similarly, composite RP materials technologies (see the sideber "Rapid Manufacturing: The Materials," at the end of this article) are a very recent development and have yet to see widespread application.

That said, RP analyst Wohlers, in his Wohlers Report 2007, a 220-page report based on a global study that surveyed advances in additive fabrication, notes that application of these technologies to the actual manufacture of end-use parts is "the next frontier."

"Considering the array of possibilities," he points out, "the market potential is enormous." Although its development will take a number of years, Wohlers predicts that, "in the meantime, compelling examples of rapid manufacturing will stimulate the development of the next generation of systems. These machines will eventually affect a wide range of industries and applications around the world. Product ideas that were once impractical due to tooling and other costs will become a reality."

Related Content

Resins, additives, adhesives and 3D printing solutions

CAMX 2023: Arkema’s broad portfolio of products for composites fabricators aim to enhance performance, durability and sustainability.

Read MorePark Aerospace launches aerospace, MRO structural film adhesive

Aeroadhere FAE-350-1 is a curing epoxy formulation designed for composite, metal, honeycomb and hybrid applications.

Read MoreFilm adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Read MoreHeat-activated foaming core rapidly achieves net-shape 3D parts

CAMX 2024: L&L Products exhibits its InsituCore foaming core structural technology, which can be used to create foam core composites minus machining or presses, as well as the Phaster A K-700, a rapid-cure adhesive.

Read MoreRead Next

Focus on Design: The promise of rapid manufacturing

Selective Laser Sintering technology and new materials abbreviate the design phase and produce a key part for a new motorcycle racing engine.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More