Redesigned bonded fasteners enable RTM railway cabinets

Adhesion Technologies Ltd. (ATL, Hampshire, UK) has developed a range of in-mold bonded fasteners, which reduce build time by eliminating the need for hole-drilling.

Adhesion Technologies Ltd. (ATL, Hampshire, UK) has developed a range of in-mold bonded fasteners, which reduce build time by eliminating the need for hole-drilling. Designed by composite engineers in conjunction with Southampton University and the UK government-funded Farnborough Aerospace Consortium, ATL’s patented products comprise more than 2,000 variants, including manganese-boron alloy, 316L stainless steel and thermoplastics as well as a castellated base option, which boosts torsional strength by 24%. Trademarked Spida Fixings, these fasteners have been designed to dissipate stress in composite structures, can be epoxy-coated to reduce risk of galvanic corrosion and are used in composite structures made via vacuum.

Recently, ATL was approached by a leading industrial composites manufacturer in the UK that developed

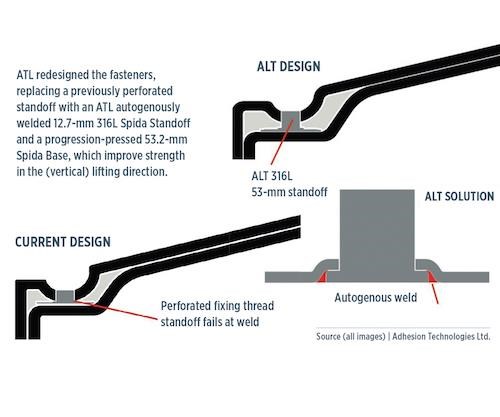

a composite solution for railway trackside control cabinets. Although these electronics enclosures are traditionally metal, they are now benefitting from composites’ improved resistance to corrosion, vibra- tion and vandalism/theft, as well as insulation against electrical conductivity. The cabinet brought to ATL weighs 1,000 kg fully assembled and features a one-piece structural roof made by RTM. Such cabinets are typically relocated multiple times throughout their lives using a crane. The crane lifts the cabinet by chain hooks connected to four removable 12-mm threaded eyebolts in the roof. Unfortunately, the fasteners for the eyebolts were separating at the interface between the nut and the perforated, welded base.

ATL worked with the manufacturer to redesign the fasteners, switching the previously perforated standoff with an ATL autogenously welded 12-mm 316L Spida Standoff and a progression-pressed 53-mm Spida Base (see photos). Stronger autogenous welding supersedes previously soldered joints in fastener components for a stronger construction: The new design is said to align the metal grain flow in the fastener with the stresses applied by chain hooks during lifting. The Spida Standoff also reportedly features a 54% increase in surface bond area thanks to ATL’s Admax surface enhancement treatment.

Samples of the trackside cabinet’s RTM roof with ATL-redesigned fasteners are being manufactured now for certification testing. New trackside enclosures will be manufactured in spring 2017 for installation next summer. ATL is now receiving more requests for technical advice and integration of their fixing solutions into similar composite products. The company exhibited the technology in CW’s Future Materials display at the 2016 International BoatBuilders’ Exhibition & Conference (IBEX, Oct. 4-6, Tampa, FL, US)

Related Content

-

Composites manufacturing for general aviation aircraft

General aviation, certified and experimental, has increasingly embraced composites over the decades, a path further driven by leveraged innovation in materials and processes and the evolving AAM market.

-

CompoTech uses integrated loop technology to create high-performance mountain bike

CompoTech features its CDuro Epona mountain bike fitted with custom suspension forks, manufactured using its AFL winding and integrated loop technologies.

-

Plant tour: Albany Engineered Composites, Rochester, N.H., U.S.

Efficient, high-quality, well-controlled composites manufacturing at volume is the mantra for this 3D weaving specialist.