Redesigning for simplicity and economy

Military OEM makes the switch from sandwich construction to compression molding to optimize composite aerospace part.

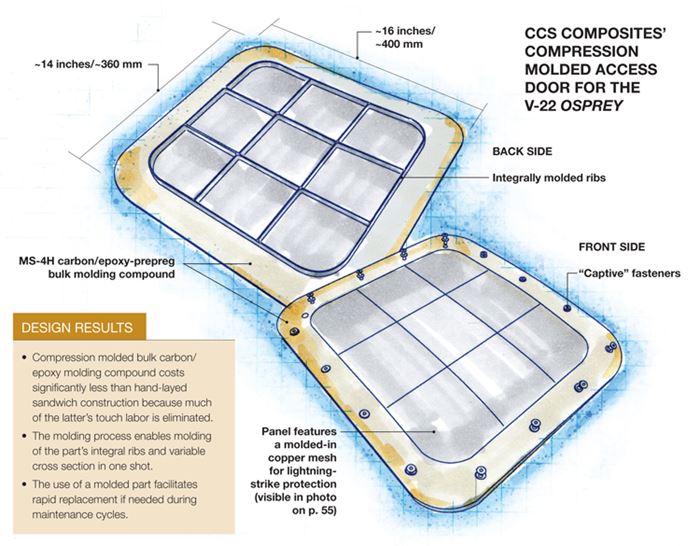

Design Results

- Compression molded bulk carbon/epoxy molding compound costs significantly less than hand-layed sandwich construction because much of the latter’s touch labor is eliminated.

- The molding process enables molding of the part’s integral ribs and variable cross section in one shot.

- The use of a molded part facilitates rapid replacement if needed during maintenance cycles.

Now that composites are firmly ensconced as enabling materials on virtually every military aircraft, the emphasis, wherever possible, is on redesigning and optimizing parts already produced in lightweight composites, with an eye to reduce cost and simplify manufacture. A recent case in point is an access panel on the U.S. military’s V-22 Osprey. Roughly 16 inches by 14 inches (40 cm by 36 cm) and 0.5 inch (12.5 mm) thick, the panel was originally designed by Boeing Rotorcraft Systems (Philadelphia, Pa.) as a typical cored sandwich, produced via hand layup using woven carbon/epoxy prepreg and an aramid honeycomb core. Although these are standard and accepted materials, and the part design and method of construction produced a lightweight part that performed well, the time and touch labor required during manufacture made it costly. Because the panel is regularly removed and remounted during the aircraft’s operational life, it is prone to accidental damage, so the need for replacement panels multiplies that cost burden. These factors drove V-22 program operators to look for an alternate approach.

Composite replaces composite

Now manufactured by CCS Composites (Fairfield, Calif.), part of TenCate Advanced Composites USA (Morgan Hill, Calif.), the access panel has undergone a complete makeover, from prepreg/honeycomb-cored construction to a compression-molded part with integral ribs. The new version reduces touch labor and allows part integration while reducing manufacturing time from hours to mere minutes.

CCS is no stranger to compression molding. The company specializes in molding parts with changing cross-sections, cocured inserts and complex geometries that challenge traditional laminate-style approaches. And the business is getting bigger. CCS recently moved its operations to a larger upgraded facility, with plenty of room for expansion, says Michael Cichon, TenCate’s director of product marketing. He adds, “We’ve made parts for military, space-satellite, thermal-management and aircraft applications.”

Cichon explains that “the material can be readily tailored for any of these types of projects by changing fiber and resin type, and we typically do concurrent engineering with customers for best results.”

“The use of compression-molded components on aircraft isn’t new,” assures Matt Cano, business development manager at CCS, noting that it has been done for years with sheet molding compound (SMC). “SMC parts are common,” he notes, “especially on commercial aircraft like the Boeing 737.”

Choosing an uncommon compound

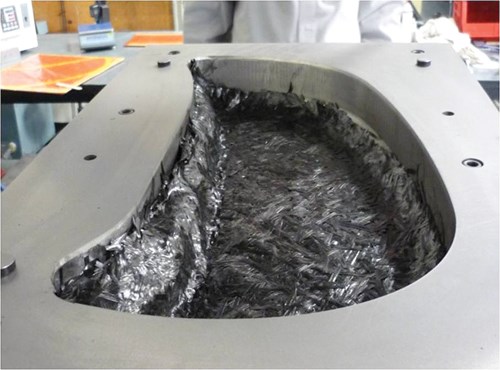

For the V-22 access panel, however, CCS selected a high-performance aerospace-grade carbon/epoxy bulk molding compound (BMC) developed by TenCate, called MS-4H. “What is unique about this application,” says Cano, “is recognizing that BMC was a better material for this composite part to significantly cut manufacturing costs and time.”

MS-4H was already a well-characterized candidate material. Fully qualified to commercial and military programs with an extensive allowables database, it was developed during years of testing and molding trials on a previous application for Bell Helicopter Textron (Ft. Worth, Texas), one of the V-22 partners. The material consists of chopped unidirectional carbon/epoxy prepreg, in pieces 0.125 inch/3.2 mm wide and 1 inch/25 mm long, made with standard-modulus carbon fiber and a proprietary TenCate toughened resin formulation with a Tg of 375°F/191°C. (For smaller parts, TenCate sells a version of the material with 0.5-inch/13-mm long intermediate-modulus fibers for better fiber distribution and equivalent or greater mechanical strength.) The discontinuous pieces create a quasi-isotropic laminate when they are randomly positioned, heated and cured under pressure.

Cano explains that a two-step process was employed to produce the MS-4H material for the V-22. First, the molding compound was produced under exacting conditions to control resin content, verified through a rigorous testing process. The BMC was then molded to produce flat test coupons. A thorough equivalency testing program was conducted on the coupons to verify material properties (see the chart on p. 56) and to ensure that the MS-4H would meet the program requirements — an effort that took more than a year to complete.

Although it has less strength than the previous prepreg/honeycomb sandwich, because the fibers are not continuous, the MS-4H compound has sufficient mechanical strength to meet the performance requirements of the panel part — that is, the panel must possess strength adequate to support itself and maintain its shape and stiffness during flight, but it is not key to airframe performance. “The legacy sandwich,” Cano points out, “was actually overdesigned for the part’s functional requirements.”

To facilitate the redesign, part models were transmitted to CCS by Boeing Rotorcraft in CATIA (Dassault Systèmes, Paris, France) format. CCS engineers worked closely with Boeing to design the new part structure for producibility in a compression molding process. The slight part curvature would be easily accommodated by the tooling design, but the stiffness afforded by the prepreg/honeycomb sandwich design had to be replicated in some way. The design solution was a panel with integral ribs on the back side, created during the molding process in one shot. Another value-added change was that the conductive copper mesh required for lightning protection, previously bonded to the outer prepreg skin in the legacy part (an extra labor step), would simply be pressed into the BMC and comolded as an integral feature, explains Cano.

The matched-metal, two-part mold used to produce the part was designed in-house by CCS, using the integrated CAD/CAM/CAE software program Pro/ENGINEER, a design suite now known as Creo, supplied by PTC (Needham, Mass.). The software allowed the tooling designers to build, visualize and operate the tool virtually to ensure an accurate fit before any metal was cut. This was advantageous because the complex steel tool had to have internal heating and cooling, fine rib details and close tolerances to handle the part geometry and operate within the compression press. Adds Cano, “We had the requisite experience to work with the customers for the best tooling solution, which again ultimately made the part easier and less expensive to mold.”

Cycle time reduction

After the tool was constructed, molding trials were conducted to validate the process. The result was a sharp contrast between the old and the new. The typical cycle time to produce the original sandwich part was at least eight hours — four or more hours to prep the tool and prepare the layup and four hours to cure it in the autoclave and then clean the tool after demolding. The cycle for the compression molded panel is typically less than 30 minutes.

The panel is produced in the following steps: The MS-4H material is preweighed and then preheated in an oven for a few minutes to soften it. Says Cano, “The charge weight, size and shape is based on our years of experience molding BMC and our knowledge of how the material reacts in the mold, including factors like shrinkage, flow and cure.” Astrostrike copper lightning strike protection (LSP) mesh, supplied by Astroseal Products Mfg. Corp. (Chester, Conn.), is placed in the mold cavity simultaneously with the MS-4H “charge” and comolded.

The demolded panel is essentially net shape and requires very little postmold finishing. Although it is possible to comold fasteners into a compression-molded part, for this part CCS drills holes in a secondary step and adds “captive” metal fasteners (which can be quickly loosened by technicians, but they stay in place when the panel is removed) and then applies an inner rubber gasket. The parts are visually inspected and undergo nondestructive testing (NDT) to ensure quality. Then they are shipped to the customer (unpainted, for this project).

The redesigned access panel is just one piece of a large cost-reduction project initiated by the Bell/Boeing V-22 program team to minimize the cost per flight hour on the aircraft — indeed, the program managers recently received the U.S. Department of Defense 2011 David Packard Excellence in Acquisition Award in recognition of significant cost cutting in both part manufacturing and follow-on maintenance and repair.

Concludes Cano, “We’re in the process of converting other cored-sandwich autoclave parts to compression molding for cost reduction. I think there will be a lot of interest in replacing composite materials with more cost-effective solutions, going forward.”

Boeing engineers report that the lower recurring price and shorter manufacturing time are the benefits of the redesign, balanced against the higher nonrecurring tooling cost.

Related Content

Machine, equipment investment strengthens Ruckus Composites’ research, innovation

CNC services expansion, universal testing machines and advanced inspection enable Ruckus to delve deeper into the study and evaluation of carbon fiber damage, as well as nondestructive and destructive testing.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreRobotic NDT inspection solutions, services enhance multitasking capabilities

CAMX 2024: Matec Instrument Companies Inc. presents its range of nondestructive ultrasonic testing technologies, including robotic inspection systems for increased efficiency and reduced physical strain.

Read MoreLoop Technology develops robotic arm for wing box inspection

Part of an R&D project with Spirit AeroSystems, the seven-axis Bravura robotic arm automates inspection and sealing within small spaces like aircraft wing boxes.

Read MoreRead Next

Developing bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More

.jpg;maxWidth=300;quality=90)