SAMPE Europe/JEC highlights

The global economy might be on the wane, but there was little evidence of it at the annual SAMPE Europe conference and nearby JEC Composites Show in Paris.

The SAMPE Europe SEICO technical conference, held at the Hotel Mercure, in Porte de Versailles, Paris, France, March 23-25, offered its usual range of highly technical presentations for engineers, starting with the keynote address by Dr. Peter Wu, chief scientist at Spirit Aerosystems (Wichita, Kan.). He gave attendees a “tour” of Spirit’s capabilities, including its 787 work and future composites parts fabrication for the Airbus A350 and the Mitsubishi Regional Jet, among others. Wu also noted research efforts with which he is involved, including nanotechnology to enhance composite part performance — e.g., improving epoxy resin characteristics and fiber-resin adhesion so that laminates might be made thinner — and three-dimensional mold-fill simulation software. When questioned about the efficacy of current automation techniques, such as automated tape layup, Wu said that it’s not a bottleneck yet. But other technologies might be in the offing once full 787 production and A350 production are under way.

Papers related to automated processing included Dirk Lukaszewicz’s (University of Bristol) outline of research funded by Airbus (Toulouse, France) to determine the impacts of prepreg type, machine type and cure on the quality of laminates prepared using automated tape laying. A paper by Mark Lamontia of Accudyne Systems Inc. (Newark, Del.) described his company’s new, patented thermoplastic tape laying head, and noted that tape quality is crucial to the quality of finished parts. In another paper, the Institute of Plastics Processing (IKV, Aachen, Germany) described new strategies for producing large structural parts quickly, as alternatives to resin transfer molding.

JEC Composites Show: Better-than-expected turnout

At the JEC Composites Show, held March 24-26 at the nearby Paris Expo, the consensus among exhibitors was that while attendance this year did not equal 2008 levels, the turnout was more robust than expected. This was due, in part, to the fact that JEC highlighted nearby Germany as the featured “guest country” as well as to JEC’s overall theme for the event, “Automation,” which attracted some new European exhibitors who offered automation solutions. Show organizers said this year’s event featured 1,065 exhibitors and more than 20,000 attendees.At a press conference, JEC’s president/CEO Frédérique Mutel presented JEC’s latest composite market study figures, which puts the worldwide market value of the composites industry at €62 billion ($82.4 billion USD) with a total volume of 8.6 million tonnes (18.9 billion lb). Despite the recessionary climate, her take is that industry growth through 2013 will be at 4 percent per annum (CAGR) with the largest growth occurring in Asia. The growth rate should be faster than the gross domestic product (GDP) growth rate, says JEC, with building and construction and wind energy as the fastest-growing market segments.

Business news & technical breakthroughs

HPC was on hand in Paris, and what follows are highlights from the JEC show floor. Look for a complete review of new products from the show in the July issue of HPC.Building on their partnership in Germany and France, Amber Composites (Langley Mill, U.K.) and Axson Technologies (Cergy, France) announced that Axson/Amber tooling materials, tooling and component prepreg will be distributed in three additional European countries. Axson customers in Italy, Spain, and Portugal now will have access to the complete package of products previously available only to aerospace, automotive and marine customers in Germany and France.

Umeco Composites (Leamington Spa, U.K.), one of the two divisions within Umeco plc, has restructured its operations into two subsidiaries, Process Materials and Structural Materials, reportedly to give “greater focus to these value-added services for customers and ensure it meets its full potential to capture market opportunities.” Umeco Composites Process Materials (UCPM) will be headed by Tim Cooper, the former managing director of Aerovac Systems, and will include the newly acquired IPM in Italy along with Richmond Aerovac and Med-Lab. Umeco Composites Structural Materials (UCSM) will be led by Jon Mabbitt, managing director of Advanced Composites Group Ltd. (Heanor, Derbyshire. U.K.), and will include the latter as well as subsidiaries Advanced Composites Group Inc. (Tulsa, Okla.), J.D. Lincoln (Costa Mesa, Calif.) and GRP Materials Supplies Ltd. (Fareham, Hampshire. U.K.).

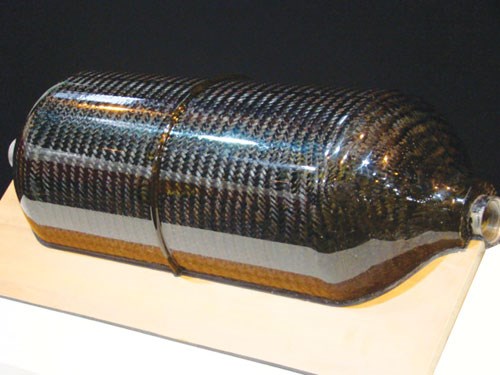

MAG Cincinnati (Hebron, Ky.) collected a JEC Innovation Award in the “Transportation” category for an unconventional hydrogen storage tank (lower photo, at right), developed in league with Profile Composites (Sidney, British Columbia, Canada) and A&P Technology (Cincinnati, Ohio). Unlike many pressure vessels, which are produced via filament winding, this pressure vessel was made by placing an A&P carbon fiber braid over an aluminum liner, followed by injection of resin via the resin transfer molding process (see top photo, at right). Cycle time for the manufacturing process is only 20 minutes. One goal of the project, funded by the U.S. Department of Energy, was to develop a high-volume manufacturing process for pressure vessels designed for alternative-fuel vehicles.

Out-of-autoclave offerings

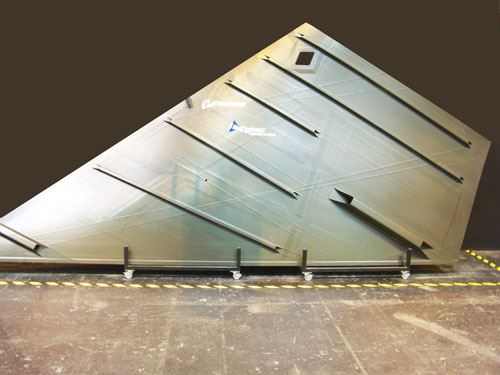

Several advanced materials suppliers used the JEC Composites Show as a forum for introducing prepreg systems developed for out-of-autoclave cure.Cytec Engineered Materials Inc. (Tempe, Ariz.) unveiled its recently developed CYCOM 5320 prepreg at a press event on the show floor. Based on the company’s well-qualified 977-3 resin system, the new CYCOM 5320 material was used by The Boeing Co. (Seattle, Wash.) to fabricate a hat-stiffened wingskin demonstrator, via vacuum bagged oven cure (see photo, p. 32). Targeted to large parts, the prepreg reportedly showed comparable performance to autoclave-cured 977-3 in company tests and is currently undergoing qualification.

Advanced Composites Group Ltd. (Heanor, Derbyshire, U.K.) showcased its oven-curable prepreg, which was qualified by Airbus for structural applications in late 2008. On display at the company’s stand was a wingbox for the Dassault Falcon aircraft made with trademarked MTM 44-1 toughened, high-performance carbon/epoxy prepreg.

Hexcel promoted its new trademarked OOA HexPly M56 for aerospace structures. The prepreg, available in woven and tape form with carbon, glass or metallic mesh fibers, yields the same properties and performance as an autoclave-cured material, says the company. The standard cure temperature is 180°C/350°F, an alternative 135°C/275°F cure cycle is possible, and out time is 30 days at room temperature.

Another proponent of out-of-autoclave processing, Quickstep Technologies Pty Ltd. (North Coogee, Western Australia), reiterated its March 10 announcement of additional funding injection to bolster the company’s growth. Philippe Odouard, Quickstep’s CEO, said the funds will provide further working capital as the company prepares to start aerospace-grade composites manufacturing from its headquarters in North Coogee, Western Australia.

Meanwhile, TenCate Advanced Composites USA (Morgan Hill, Calif.) said its new prepregging line offers an alternative to thermosetting prepregs in its trademarked CETEX carbon fiber/PEEK and glass fiber/PEEK thermoplastic prepregs. Intended for primary aerospace structures, the prepregs have low void content (less then 1 percent), and are suitable for press lamination, thermoforming or autoclave processing.

Related Content

Hitachi Rail chooses Roboze printers, materials including carbon fiber/PEEK for railway spare parts

The Roboze ARGO 500 will be used at Hitachi Rail factories in Naples, Italy and Maryland, U.S. to reduce cost and delivery times for prototypes and spare parts.

Read MoreFormula 1 team adopts Roboze 3D printed composites

The Visa Cash App RB Formula 1 team is collaborating with Roboze to reduce weight and create parts with complex geometries via carbon fiber/PEEK.

Read MoreQueen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

Read MoreEaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Read MoreRead Next

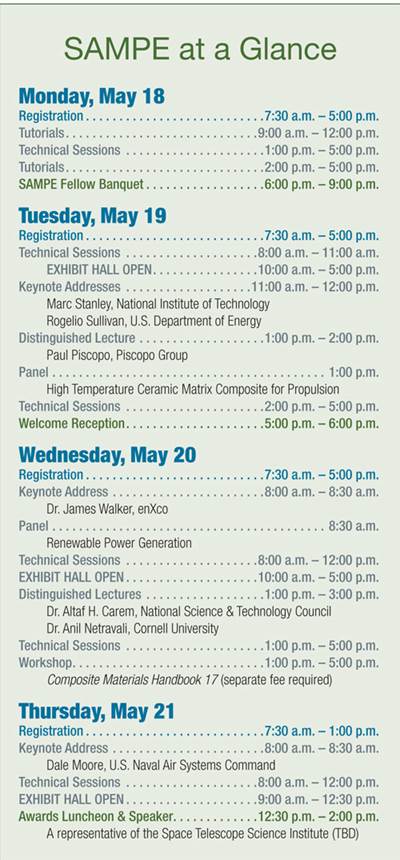

SAMPE 2009 Preview

The Society takes its U.S. trade show back to Baltimore, expecting to prepare advanced materials professionals for uncertain economic times.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More