Plant tour: Elbit Systems Ltd., Haifa, Israel

Military and commercial tier supplier Elbit Cyclone maintains precision and quality as it continues growth in composites, complex assemblies and high-rate production.

Elbit Systems Ltd. (Haifa) is Israel’s largest defense contractor, with a turnover of US$3.3 billion in 2017 and a backlog of more than US$7.5 billion in 2018. Its activities include systems and structures for military and commercial aircraft, land vehicles, homeland security and a variety of intelligence, electronics and cyber systems. Of its 12,500 employees, almost 3,000 are in the US, working with its subsidiary Elbit Systems of America, which maintains multiple locations, including in the US states of Utah and New Hampshire and in Ft. Worth, TX, US. And Elbit Cyclone has expanded to an additional site, called Aero-Structure Technologies Cyclone (ATC), near the Tbilisi, Georgia, international airport, built in partnership with the Georgian government. Construction of a 12,000m2 facility, equipped with two autoclaves and CNC machining and NDI capability, is complete. “We are working now to qualify this location with major aircraft OEMs,” says Jonathan Hulaty, Elbit Cyclone senior manager for business development and marketing.

The Elbit Systems Cyclone subsidiary is based in the north of Israel, and serves as a design and production center for metal and composite aircraft structures and assemblies. The company stands on the same site, near Karmiel, where Cyclone was established in 1970, in a single building, to provide maintenance, repair and overhaul (MRO) services for Israel Air Force aircraft and helicopters. The spiral wind generated by whirling helicopter blades inspired the original company name.

Cyclone had established composites capability by the 1980s, and began work for customers outside of Israel, building metal doors for McDonnell Douglas DC-10 and MD-11 widebody aircraft, and parts for F-15 and F-16 military jets as well as the Gulfstream G-200 business jet.

Elbit acquired Cyclone in the late 1990s, invested in the company, and by 2010, it had tripled in size. By 2017, Cyclone had produced 11,000 aluminum doors for The Boeing Co.’s (Chicago, IL, US) 737 commercial aircraft, including aft entry doors, both galley doors and both aft and forward cargo doors. It then contracted directly with Boeing for production of composite floor assemblies and detail parts for the 787 Dreamliner, and with Spirit AeroSystems (Wichita, KS, US) for composites parts in fuselage Section 41 of that same aircraft. It also supplies passenger floor beams for the Boeing 787-8 variant. The company is now recognized as a Boeing Gold Level Preferred Supplier, Boeing’s highest supplier award. Cyclone is one of the few that have achieved it and is the first outside the US.

The company also supplies parts for Bombardier’s (Montreal, QC, Canada) long-range business jets and various parts for three variants of the US-anchored F-35 Lightning II. Other notables on Cyclone’s long customer list include Lockheed Martin, Sikorsky, GKN Aerospace, Textron, Triumph, Northrop Grumman and Bell Helicopter.

Hulaty, CW’s host for the tour, recalls, “In the late 1990s, we had 400 employees. Now, we are five times larger in sales, with 500 employees. This is possible thanks to our emphasis on lean processes. Most of what we do is build to print, which may not sound glorious, but it accounts for a large portion of our industry.” Hulaty adds that quality, repeatability and competitiveness requirements, coupled with the equipment and quality systems investment necessary to meet production, makes this a tough but interesting position in the market: “Being an aerospace composites tier supplier is not for the faint of heart.”

Far from fainting, Cyclone saw its composites business surge past its metalworks last year to comprise a majority of its production, with a roughly 60/40 split. Hulaty forecasts the growth will continue: “This year, we will probably move to 70% composites.”

Parts proficiency

CW’s tour begins in the site’s main conference room, where Hulaty gives a brief introduction. Cyclone’s production, he explains, is split about 50/50 between military and commercial. Commercial composite parts include landing gear doors, nacelle parts, skins, fairings, control surfaces and structural floor grids. Military composites include skins, doors, filament wound external tanks, pylons, control surfaces and helicopter sponsons and engine intakes.

Cyclone also designed the outer wing and tail boom for a medium-altitude, long-endurance unmanned aerial vehicle (MALE UAV) that flies at 3,048-9,144m altitudes for extended (e.g., 24- to 48-hour) durations. However, Hulaty notes, the company doesn’t do much UAV work anymore. “UAVs are typically small, using wet layup, which is not our expertise,” he explains. There are larger UAVs made using prepreg, but Hulaty points out that these are typically produced in smaller quantities or produced in-house by Boeing, General Atomics and other large defense OEMs. “We prefer long serial production of prepreg parts vs. sporadic programs.”

Cyclone’s prepreg parts capabilities include vacuum debulking of multiple layups via hot drape forming (HDF) and autoclave cure. Nondestructive inspection (NDI) and CNC machining of cured parts is completed on site, and a special expertise is high-rate production of complex metal and composite assemblies. Cyclone has completed all aerospace manufacturing and quality certifications (e.g., AS9100, Nadcap, ISO9001) and has developed capabilities in filament winding and resin transfer molding (RTM).

RTM was, in fact, CW‘s first introduction to Cyclone. The company’s development of a unitized, all-composite alternative to metal passenger doors on commercial aircraft was featured in the 2013 CW article “Cutting the cost of integrated composite aerostructures.” The technology used RTM and geometrically locked composite fittings to achieve an FAA-certifiable structure with very few fasteners, 30% weight savings and 25-35% cost reduction vs. aluminum and “black aluminum” composite designs. Cyclone’s successful build of an entirely fastener-free composite door as well as extension of the technology to lighter-weight, lower-cost composite aircraft control surfaces was described by CW in a 2016 update titled “Fastener-free, composite aircraft door and control surfaces.” Hulaty concludes his introductory remarks by pointing out fastener-free Door #1, on display in the conference room. The part is impressive, with a high-quality finish. Then he leads the way out of the building.

Streamlined layup and testing

Hulaty leads the tour down a hill, then turns left into the entryway of Cyclone’s composites production building. Several parts are showcased here as well: Boeing 767 tail skid fairings, a Beechcraft King Air winglet and F-35 composite parts. Past the entrance, a restricted-access cleanroom for defense-related production remains closed on the left. On the right, workers in the cleanroom for Boeing 787 parts lay up prepreg for an array of parts, from small clips and stanchions to complex J-, I- and C-beams, as well as multi-piece nose landing-gear doors. Prepreg is cut using a Bullmer Assyst (Wakefield, UK) automated fabric cutter and a guillotine machine for cutting thick stacks at any angle. The prepreg freezer is adjacent to the cleanroom. Hulaty notes that sometimes stacks of prepreg are cut, kitted and put back into the freezer. Aligned Vision (Chelmsford, MA, US) laser projection systems located throughout the cleanroom assist hand layup.

Carbon fiber-reinforced plastic (CFRP) floor beam parts are being laid up on male metal mandrels. Hulaty details the streamlined process, “We lay up the prepreg stacks first and then apply them to the mandrel. This saves a ton of time vs. applying piecemeal onto the tool. The layups are then covered, with a CFRP caul of our own design, which helps to ensure 100% repeatability in the parts.”

A hot drape forming machine sits along the back wall of the cleanroom, enabling debulking of many parts per cycle. “I don’t know how you do this type of high-rate prepreg parts production without hot drape forming,” says Hulaty in reference to parts such as beams and stanchions. And yet, he acknowledges this step is not the bottleneck, nor is the autoclave. “Machining at the end, after curing, is the bottleneck,” he maintains, explaining that for long floor beam parts, it is faster to lay up a simple stack and machine it after cure. “The autoclave is not the issue because we can stack a lot of parts to cure at one time,” he adds. “So, we actually get a good production rate per cure cycle.”

In a large adjoining area, four autoclaves sit along the back wall. “Getting the size right for your autoclaves is tricky,” contends Hulaty, “because you’re trying to balance production rate and getting enough parts per cycle, with not having too large of a volume to heat up and cool down, which takes time.” Cyclone’s 3m-diameter autoclaves supplied by Thermal Equipment Corp. (TEC, Rancho Dominguez, CA, US) range from 5m and 10m in length to the longest, at 11m.

A mezzanine above the autoclave bay houses a quality assurance testing department. Here, Zwick (Ulm, Germany) testers have climatic chambers for temperature cycling, required for testing materials used on aircraft control surfaces. “These perform temperature and load cycling, in accordance with OEM specs,” says Hulaty. “We do all testing in-house and can perform materials qualifications because almost all of our customers have visited and qualified our lab.”

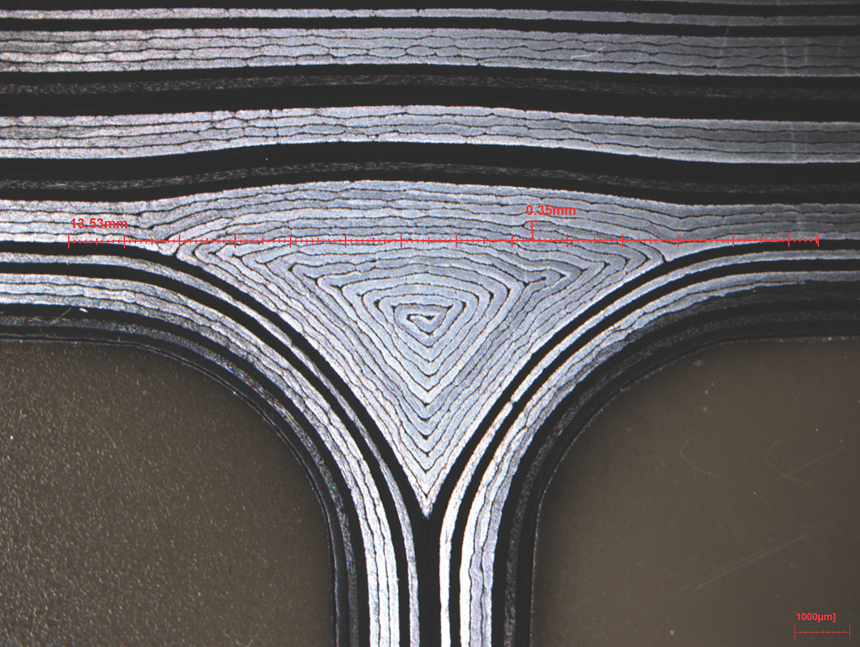

He shows micrographs of a CFRP radius filler (“noodle”) fabricated by Cyclone, used in various prepreg beam construction. “This is a very complex issue when you are making parts where the flange of the beam must connect to the web and a noodle is used to enable load transfer and prevent voids,” Hulaty explains, leading the tour into a second test lab, where small disks are polished and placed into Tegramin test equipment made by Struers (Ballerup, Denmark). “This tests the coherence of our layup process,” he points out, emphasizing, “We test this ourselves, not to meet any customer requirements, but instead to make sure that we are doing well with our own processes, adhering to our own quality standards.”

NDI and machining

The tour next visits an adjacent facility, which houses final quality assurance (QA) and machining operations. The high-ceilinged NDI area houses a large through-transmission ultrasound (TTU) testing machine supplied by Matec Instrument Cos. (Northborough, MA, US) on the left, complete with water squirter for coupling the sound waves to the part surface. “One side of the TTU equipment can transmit and receive while the other is a receiver only,” Hulaty explains. “With this, we can scan medium-to-large parts, such as a belly fairing for a business jet, in half an eight-hour shift.” He claims this is the largest TTU system used in Israel for NDI, adding: “We scan every piece of composite that we make. Fairings can sometimes go to statistics-based inspection after a while, because they are secondary structures, and not flight critical, but we still prefer to scan every one.” In line with this preference, Hulaty notes that Cyclone employs two Level III nondestructive testing (NDT) technicians for composites.

Continuing through the lab, on the right is another automated ultrasonic testing (UT) machine, this one made by ScanMaster Systems Ltd. (Rosh-Ha’ayin, Israel). Although composite parts are submerged in tanks of water here as well, this is not for a C-scan system. Instead, the tanks serve phased-array UT, a very fast method that provides greater accuracy than a C-scan, but for simpler shapes.

As the tour moves past racks of parts in various stages of the QA process, Hulaty points out tooling stored next to the NDT bay. “We design and build most of our tools in-house, both metal and composite, but some customers prefer to supply their own. We may also make changes to the tooling design to improve production, of course, only with customer approval.”

Through a door and short hallway, the tour enters CNC operations, which house twin 5-axis CNC machining centers supplied by Breton (Castello di Godego, Italy), a company originally established in the stonecutting industry. “Breton machine components were built with protection against stone dust,” says CNC engineering manager Trevor Hutson. “Thus, they work well with CFRP. We found woodworking CNC machines were not robust enough for our production needs.”

Hulaty points out that the building temperature is maintained at 26°C ±1°C. “Each machine will stop if any of its parameters are out of spec,” he explains. The machines can handle parts up to 5m long and 2.2m wide with 1m travel in the z direction. Their volumetric accuracy is cited as 50 microns (0.002 inch).

Once machining is complete, a coordinate measuring machine (CMM) head is switched in and performs CMM on the part for final QA. This is reported and included with the part through the machine’s digital control system to save inspection time. “We calibrate the CMM probe, then we take the part measurements,” says CNC engineer Karin Hartman, who, alongside Hutson, functions as Cyclone’s second CNC machining expert. “This provides real-time results, so we can deal with any issues before we migrate them to more than one part,” Hutson adds. “It also saves time, allowing any re-machining to be done right away.”

Assembly and R&D

Here, the tour exits the NDT/CNC building for a walk back up the hill past the building that housed the conference room to an adjacent structure, which accommodates assembly operations. Hulaty points out the many assembly stations, which produce the floor beams, flight deck beam, shear web beam and electronic equipment (avionics) bay for the 787’s Section 41. These, along with the nose wheel well door (NWWD), will ship to Spirit AeroSystems in the US, ready to drop in to that company’s production line for the 787 Section 41, the forward fuselage section.

Looking at the shear web assembly station in greater detail, Hulaty explains that it supports the Section 41 cargo floor, providing transverse support across the plane’s belly. The assembly includes two lengthwise beams plus six stanchions, all assembled upside down. A simple rotating jig holds the parts together to facilitate fastening of the stanchions.

“Composites enter here already drilled,” notes Hulaty. “Only metal is drilled in this building.” Metal also is anodized and painted at the back of the building. Assembly instructions are displayed on a computer monitor at each station, using an off-the-shelf system. “But the instructions are ours,” he says. “We modified it to talk to the CATIA models for each part, and then our engineering department created the assembly instructions.” He explains that the color red indicates a change or mistake made in the past. “It’s a near-paperless environment, enabled by touch-screen infrastructure. Route cards follow the part electronically.”

Moving on, Hulaty points out an anti-missile system for commercial aircraft, called C-MUSIC (commercial-multi-spectral infrared counter measure). It was developed by Elbit Systems ISTAR division, and Cyclone designed the system’s structure, including in-house generated allowables. Although the system mechanisms and interior structure are metallic, its fairing/radome is composite.

“All Israeli airlines must be equipped with this,” he says. “It is an autonomous system mounted on the plane’s belly via a kit that is plug-and-play. Designed to counteract man-portable, shoulder-launched, heat-seeking missiles, a laser is shot at the incoming missile if this system is activated.” First deployed on a Boeing 737 in 2013, Hulaty says C-MUSIC systems have thousands of operational hours on commercial aircraft and have been tested on the Embraer 170 and 190 as well as most Boeing commercial platforms and several Airbus (Toulouse, France) models.

Across the street in the R&D lab, the entry hallway showcases a variety of parts, including some made from 3D-printed titanium. CW learns that the latter resulted from the activities of an Israeli consortium led by Elbit-Cyclone head of R&D Lior Zilberman. The consortium’s goal was to advance additive manufacturing technology for aerostructures production. “We are also interested in its potential to augment our assembly capabilities,” Hulaty says. Additional uses may include parts for helicopter upgrade programs, which he notes are notoriously small runs (e.g., five helicopters), “so tooling up is not an affordable option.” Other parts in the R&D showcase include a marine propeller made with RTM and a winglet developed with a customer to replace a two-piece honeycomb assembly with a simple, integrated part.

Developing unitized composite structures has become one of Cyclone’s strengths. The winglet uses monolithic carbon/epoxy prepreg processed out of autoclave (OOA) to reduce weight, cost and lead time. The same advantages are achieved in an integrated, fastener-free control surface, made in a one-shot RTM process. Zilberman has also led the company in development of multifunctional structures with embedded energy harvesting, shape-morphing capability and structural health monitoring/NDI systems in rotary and fixed wings, as well as self-adaptive composite rotary and fixed wings.

The R&D lab comprises a cutting room, machining room and RTM development room. The latter contains a 360-ton press by Lauffer Pressen (Horb am Neckar, Germany) with a 700-kW power system for heating molds for parts up to 2 by 2m. Cyclone worked with Polymer G (Halutza, Israel) to develop the resin injection system for the integrated, fastener-free passenger door and control surface technology. There also is a large oven for preheating the RTM molds and/or postcuring the epoxy resin parts.

Investment in future production

As the tour concludes, Hulaty notes that high-rate production and assembly requires investment. Through the tour, we have seen examples of this in Cyclone’s testing labs and NDI capability, as well as its approach to machining. The company also implemented Plataine’s (Waltham, MA, US) Total Production Optimization (TPO) software, used to achieve double-digit material savings in its prepreg cutting operations. TPO replaced the previous sequential cutting and nesting of prepreg with an automated, digital system that optimizes cutting nests across multiple parts using the same materials. This system has also helped to improve manufacturing yield and reduce time required for cutting as well as machine set up.

“We are trusted by our customers to deliver high-quality parts, but we must also constantly look at ways to manage cost and enable increased production rates,” says Hulaty. Elbit Cyclone continues to look for new opportunities and sees a bright future, albeit full of challenges. “We have a firm strategy, which is proving itself, as seen by the company’s growth,” says Hulaty. “That being said, our strategy is ever-evolving, adapting to market changes.” The impression that lingers is a pragmatic confidence based on knowledge and experience, a company that will continue to fulfill its role of converting the promise of advanced technology into reliable aerospace composites production.

Related Content

Optimized approach to predict delamination failure in CFRTP structures

ARRK Engineering and Mitsui Chemicals improved delamination prediction accuracy to help optimize absorbed energy/failure load for an overmolded TAFNEX CF/PP UD tape bumper beam.

Read MoreJeep all-composite roof receivers achieve steel performance at low mass

Ultrashort carbon fiber/PPA replaces steel on rooftop brackets to hold Jeep soft tops, hardtops.

Read MoreThe basics of composite drawing interpretation

Knowing the fundamentals for reading drawings — including master ply tables, ply definition diagrams and more — lays a foundation for proper composite design evaluation.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)