Smart Aircraft Structures: a Future Necessity

Health monitoring of aircraft structures using distributed in situ sensor systems.

Health monitoring of structures is a major concern in the engineering community. The need is acute in aging aerospace and civil structures, many of which are operating well beyond their initial design lives. The current damage tolerance design philosophy requires that a structure be capable of sustaining small damage without failure and that a nondestructive inspection (NDI) program be instituted to detect such flaws before they grow to critical size. This approach recognizes the impossibility of establishing complete structural redundancy — the “fail safe” design premise — and emphasizes inspection to ensure safety and reliability. However, inspections often must be carried out in hard-to-reach locations and on complex joints and geometries.

Furthermore, the damage tolerance and high strength-to-weight ratio of composites have motivated designers to expand the role of advanced materials in aircraft structures. A boon to manufacturers, composites present unique challenges to aircraft maintenance and repair organizations (MROs). Composite lay-up processes permit manufacturers to produce fewer, more complex parts, consolidating previously separate metal parts. This practice, however, further complicates inspection. Though well-established procedures exist to detect the effects of structural fatigue, recent and unanticipated failures of aircraft and civil structures have compelled the engineering community to take a fresh look at current design philosophies and reassess the effect of structural aging. As a result, the aviation industry has recognized the need for more sophisticated structural health monitoring (SHM) systems and more innovative ways to deploy them in situations where complex structural geometries create accessibility limitations that may impede efforts to locate and identify deeply hidden flaws. Considerable research is currently being directed towards (1) development of new and better nondestructive inspection techniques and (2) development of SHM sensors and systems.

NDI systems examine a material to determine geometry, damage or composition by using technology that does not negatively affect the structure’s future usefulness. NDI techniques involve the use of discrete testing devices that must be in contact with or adjacent to the surface of the structure. This requires that the aircraft be on the ground and typically involves extensive local inspections that are deployed with a high degree of human interaction. Adequate access to certain structures may require expensive and time-consuming disassembly.

SHM, by contrast, involves the use of “smart structures,” that is, NDI principles coupled with in-situ sensors that are incorporated into the structure. These sensors produce an NDI tool with greater access to difficult-to-inspect areas of complex structures and can eliminate the need for disassembly. SHM, therefore, is perceived as a revolutionary approach to assessing the integrity of structures. The core of SHM technology is the development of self-sufficient systems that use built-in, distributed sensor/actuator networks not only to detect structural discrepancies and determine the extent of damage but also to monitor the effects of structural usage. SHM can provide earlier warnings of physical damage, which can be used to define remedial strategies before the damage compromises airworthiness. Soon, it may be possible to quickly, routinely and remotely monitor the integrity of an aircraft structure while in service.

SHM: An answer to rising maintenance costs

SHM is a timely development because the costs associated with the increasing maintenance and surveillance of aging infrastructure are rising at an unexpected rate. Aircraft maintenance and repairs now represent about a quarter of a commercial fleet’s operating costs. The application of SHM would enable true condition-based maintenance in lieu of maintenance checks based on time of operation. Although expected maintenance functions will already be defined (just as they are in today’s conventional MRO practices), they will only be carried out as need is established by the health monitoring system. Further, the replacement of our present-day manual inspections with some form of automated health monitoring would substantially reduce the associated lifecycle costs. Hence, there is a need for reliable SHM systems that can autonomously process data, assess structural condition and signal the need for human intervention. Further, flaw growth and structural failure could best be monitored by onboard SHM systems that continuously, rather than periodically, assess structural integrity.

SHM research under FAA/Sandia

The FAA Airworthiness Assurance Center (AANC) at Sandia National Laboratories (Albuquerque, N.M.) has been addressing the need for SHM. In addition to mature micro-electro mechanical systems (MEMS) devices, such as acoustic emission sensors, accelerometers, strain gages and pressure sensors, recent advances in micro-sensors have produced miniature eddy current, ultrasonic, piezoelectric, fiber-optic and other devices that lend themselves to damage detection. These sensor systems range in maturity from laboratory-based prototypes to turnkey products that appear ready for use.

To be of practical use, SHM sensors should be low-profile, lightweight, easily mountable or embeddable, durable and reliable. To reduce human error with respect to flaw identification, the sensors should be easy to monitor, with minimal need for the user to perform additional data analysis. For optimum performance, the key element is detailed calibration of sensor responses, so damage signatures can be clearly delineated from sensor data produced by unflawed structures.

Unlike today’s NDI techniques, which are, by nature, local inspection systems, SHM systems can support sensor networks capable of collecting data on entire structures without the delays involved in serial, small-area inspection. When combined in a systems approach that includes sensors to monitor not only structures but also electronics, hydraulics and avionics, SHM can provide an aircraft prognostic health management architecture that can assist in maintenance scheduling and tracking.

Since early damage detection reduces the need for subsequent major repairs and can eliminate the need for component tear-down, the aerospace industry will have one of the highest payoffs from SHM applications. However, SHM could have wide use in automotive, civil infrastructure and industrial structures.

The SHM methodology also can benefit from the use of artificial intelligence and neural network algorithms that extract damage features based on a learning process. In fact, deployed SHM systems will become another tool for the aircraft designer, who can use the field data to develop new concepts in both design and maintenance of structures. Ongoing, focused validation programs at the AANC — conducted jointly with aircraft manufacturers and airlines — seek to integrate SHM sensors into aircraft maintenance programs. These evaluations will incorporate cost-benefit analyses and include statistically derived performance reliability data.

Deployment of SHM networks

Distributed sensor networks can be deployed in any of the three approaches listed below. These options are listed in the order of increasing complexity; however, less labor is required to monitor the systems as they become more complex.

In-situ sensors only. In this simplest approach, the sensors are the only items permanently installed on the structure. At the desired inspection intervals, the aircraft must be on the ground. Power, signal conditioning and data acquisition electronics must be manually transported to the aircraft. The sensors are linked to the monitoring electronics via an electrical connector, and flaw detection procedures are conducted on site.

Sensor network with in-situ data acquisition. In this system, miniature packaged electronics, placed in-situ with the sensor network, have the power, memory and programmable circuitry necessary for automated data logging in flight or on the ground. However, the gathered data must be downloaded periodically by a technician via manual hook-ups on the ground.

Sensor network with real-time data transmission to a remote site. Technology also exists to co-locate the processing electronics with in-situ sensor networks to conduct structural health diagnostics in real time. This third approach is similar to the second, but adds a telemetry system that enables continuous, wireless transmission of data — in the air or on the ground — to a remote site. A Web site can be programmed to interrogate the data and use preset thresholds to provide continuous green light/red light information regarding structural health. Further, the Web site can be programmed to automatically send an e-mail to maintenance personnel if there is a need for repairs or other maintenance. In this mode of operation, it may be desirable to incorporate interface electronics to condition the signals and analyze data in-situ. This eliminates the need to transmit larger raw data files.

Sandia Labs also has studied the use of energy harvesting methods that can power sensors systems by converting structural stresses (strain energy harvesting) into electrical power via piezoelectric transducers. This work also includes the use of radio frequency (RF) tagging technology to remotely read data from the sensors.

Taking the next step

While recent advances in onboard sensors have demonstrated that distributed and autonomous SHM systems reliably detect incipient damage, commercial implementation still needs to be proven. Moreover, there is a growing demand from the aerospace sector, both in government and private industry, for standardized procedures and implementation of SHM technologies. For these reasons, a group of people working in the SHM arena has initiated the Aerospace Industry Steering Committee (AISC) for SHM. The SHM AISC consists of representatives from industry, R&D insti- tutions, universities, the FAA and the European Aviation Safety Agency (EASA) and government agencies, the U.S. Department of Defense (DoD) and NASA. The first AISC meeting took place at Stanford University in November 2006, to create the AISC charter.

The mission of AISC is to develop an approach for standardizing both integration and certification requirements for SHM of aerospace structures. Ultimately, AISC will develop a guidebook that will specify the approach for SHM use on air and space vehicles and identify technology gaps that impede SHM use.

This month (January 2007), SHM AISC intends to form its Working Groups. AISC’s Main Committee and its Working Groups are scheduled to meet in March 2007 at the Airbus facility in Germany. The first task for Working Groups will be to review qualification and certification processes and procedures used today by FAA and EASA. Among their many tasks, the groups also will develop guidelines that FAA/EASA can use to generate new or revised certification requirements. AISC also will actively promote the use of SHM and encourage industry and government participation.

A real-time and real-world solution

The use of in-situ sensors for real-time health monitoring of aircraft structures appears to be a viable option in the near future. Reliable SHM systems can automatically process data, assess structural condition and signal the need for human intervention. Recent requests for real-time monitoring of structures have produced a niche for active sensor systems that use technology such as remote field eddy currents, fiber optics, piezoelectric materials, and Comparative Vacuum Monitoring (current applications of fiber-optic sensor systems are discussed on pp. 34 and 44). Whether the sensor network is hardwired to a terminal within the aircraft or monitored in a remote, wireless fashion, it can be interrogated in real time. However, sensors most likely will be examined at discrete intervals, probably at normal maintenance checks. The important item to note is the ease with which an entire network of distributed sensors can be monitored, which means that structural health assessments can occur more often, allowing operators to be even more vigilant with respect to flaw onset.

Related Content

VIDEO: AI, cameras and lasers for FOD detection

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

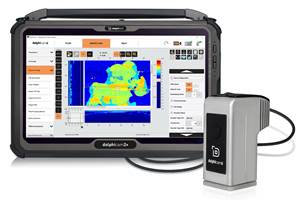

Read MorePortable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

Read MorePhotothermal tomography system enhances composites NDT

JEC World 2024: Austria-based voidsy GmbH introduces the 3D V-ROX system, facilitating fast, contactless and nondestructive inspection with added efficiency and safety.

Read MoreNDT inspection services, automated systems serve aerospace needs

CAMX 2023: Arcadia Aerospace Industries demonstrates its commitment to navigating the rapidly changing aerospace manufacturing landscape with robotic-based machines and motion control systems, certified facilities for NDT services and conducted training and recruitment.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More