NDT inspection services, automated systems serve aerospace needs

CAMX 2023: Arcadia Aerospace Industries demonstrates its commitment to navigating the rapidly changing aerospace manufacturing landscape with robotic-based machines and motion control systems, certified facilities for NDT services and conducted training and recruitment.

Share

Arcadia Aerospace Industries (AAI, Punta Gorda, Fla., U.S.) specializes in providing comprehensive solutions for composites including inspection, engineering, quality and special process manufacturing. Its facilities demonstrate the commitment and ability to compete at the highest levels in the aerospace industry, meeting AS9100/ISO 9001 aerospace quality and NADCAP special process certifications via the company’s central e-QMS system.

AAI operates a network of nondestructive inspection (NDI) facilities staffed by experienced, certified personnel who are available 24/7. These facilities work closely with a customer’s materials engineering teams to determine testing requirements, methods and processes in order to meet the demands and schedules of aircraft programs.

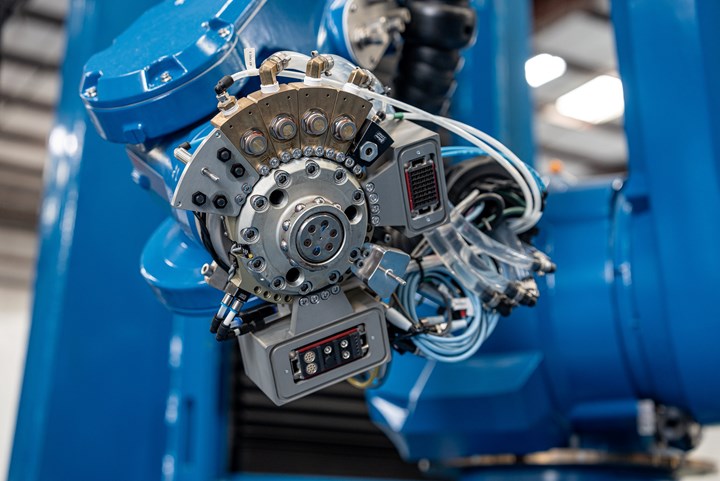

AAI has a strong track record in developing robotic-based machines and motion control systems. Its engineering team uses advanced automated robotic machinery specifically tailored to meet the requirements of aircraft components and production throughput. This machinery, with incorporated state-of-the-art motion algorithms seamlessly integrated into a single platform, ensures high-quality data for conformance analysis. AAI’s robotic systems are capable of complex contouring and feature automatic tool changing capabilities. They employ ultrasonic, thermographic, radiographic and optical technologies to detect quality issues in virtually any aircraft structure. These automated systems employ secure, database-style processing of large amounts of critical inspection data, which can be accessed remotely.

Moreover, AAI enables its customers to navigate the rapidly changing aerospace manufacturing landscape through its Co-Location model for client partners. This model allows AAI’s teams to secure space within a manufacturer’s facilities to install the necessary automated machinery assets and personnel. AAI establishes certified and accredited inspection departments and provide services on a fixed price per part basis. Its teams provide turnkey solutions that are said to seamlessly integrate with a customer’s in-house tracking systems and encompass all aspects of quality inspection special processes.

AAI also actively conducts comprehensive training and recruitment programs across various NDI and engineering platforms, while promoting growth opportunities. As part of the Applus Laboratories family of companies, AAI benefits from the strength and resources of an organization with more than 20,000 employees operating in 70 different countries.

Related Content

-

VIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.