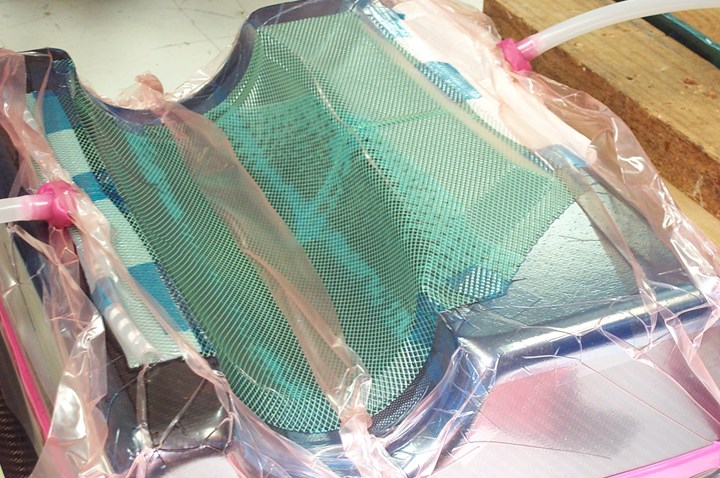

Photo Credit: Abaris Training Resources

The impregnation and consolidation of composite laminates via atmospheric pressure in the vacuum infusion process (VIP) is a well-established procedure for the production of high-quality components and structures, and has been adopted by many composites fabricators for several reasons:

- Removes air trapped between plies

- Compacts fiber layers and prevents shifting of fiber orientation during cure

- Extracts moisture, solvents and volatiles from curing composites

- Achieves a higher fiber-to-resin ratio

- Is a cleaner, less wasteful and more efficient process compared to hand layup

- Helps in producing low volumes of large structures minus an autoclave

- Allows for the use of a variety of molds and custom shapes.

As a result, vacuum infusion continues to show promise for end markets such as wind, aerospace, automotive and marine.

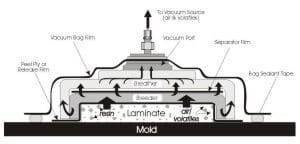

However, VIP is also, arguably, a complex process, and involves a variety of processing materials and steps for proper implementation, including the use of release film or peel ply, a bleeder, separator and breather layer, various tapes for sealing and vacuum pumps to remove air from the laminate. With it comes an equally complex range of suppliers and distributors that offer customers a variety of products.

This is the fifth in a series of Tech Tables that CW has published, each designed to provide as comprehensive a list as possible of suppliers, their products and selected product specifications.

This table of vacuum bagging supplies has been built with data provided by suppliers, and is intended to provide a representation of the products they offer. To further simplify the table, CW only focuses on the basic categories of materials for vacuum bagging for conventional out-of-autoclave (OOA), wet and prepreg layup processes; additional bagging and plumbing provisions are not detailed.

Moreover, while CW was unable to receive data from all vacuum bag suppliers, prominent companies unlisted — but which should be distinguished in this area — include Aerontec, AeroWindTech, Fibretex Nonwovens A/S, Guarniflon S.p.A, Gurit USA, Hauflier Composites GmbH, Hawkeye International, Smooth-On Inc., Wacker Chemie AG and Warm Industrial Nonwovens.

Download the PDF of this table here, or at short.compositesworld.com/VIPTechTable21final

|

Company

|

Release Films and Peel Ply |

Bleeders |

Breather Layers |

Breather Yarns/Cloths |

Flash Tape |

Sealant Tape |

Bagging Film |

Reusable Vacuum Bags |

Vacuum Ports |

||||||||||

|

Peel ply material type(s) available |

Nonporous (NP) or porous (P) |

Release film material type(s) available. |

Perforated release films: Diameter and spacing of the holes |

Material type(s) available |

Thickness and weight offered |

Breather woven/nonwoven fabric type(s) |

Amount of pressure (psi) that can be exerted upon it |

Breather yarn/cloth(s) roll size(s) available (in) |

Recommended working temp |

Material type(s) available |

Material type(s) available |

Material temp range (F/C) |

Film type(s) available |

Film material range (F/C) |

Potential applications |

Material type(s) available |

Size(s) available (in) |

Minimum number of ports |

|

|

Nylon, polyester, teflon and silicone-coated glass, aramid fabrics. Available in a wide range of weights, widths and operating parameters |

NP |

Polyolefins, fluoropolymers, polyimides |

Available in all industry-standard spacing and diameters. Hot and hot perforated in 14 spacing and diameter options |

Nonwoven nylon, polyester and various fabrics such as fiberglass |

Wide range of industry-standard weights and widths |

Nylon, polyester and various fabrics such as fiberglass |

Varies by type of material, temp, thickness, weight and other factors |

N/A |

N/A |

Available in a variety of substrates, thicknesses and widths. Options meet all operating environments. Examples: polyester w/ silicone, rubber and acrylic pressure-sensitive adhesives, PTFE, nylon, polyimides and fluoropolymers |

Butyl rubber and silicone types |

Up to 752/400 |

Construction options include nylon, fluoropolymers, polyimdies, multilayer co-polymer films. Bagging formats unclude sheet stock, tubular, precut and fold configurations. Custom kitting and precut formats available |

Temp ranges up to 800/427 |

Aerospace, marine, wind, glass lamination, automotive, sports and recreational |

Cured and uncured silicone, Viton sheet stock and customizable spray silicone bag construction |

All standard imperial and metric measurement vacuum fittings and ports |

Minimum order quantity of 1 |

|

|

Nylons, polyester, fiberglass with PTFE or silicone coating and aramid |

NP |

Polyolefins, fluoropolymers, polyimides |

All industry-standard perforations |

Polyester, nylon, fiberglass |

A range of weights, thicknesses |

Polyester, nylon, fiberglass |

Depending on density and cure temperature, polyester and nylon breather can withstand 100-200 psi. Fiberglass breathers available for higher temperatures, pressures. |

N/A |

N/A |

Flashbreaker tapes in polyester with silicone, rubber and acrylic PSA. Other substrate types available: PTFE, fluorpolymers, nylon and polyimide |

Butyl rubber and silicone types |

RT to 800/427 |

Nylong, multilayers, fluoropolymers, polyimide |

Spectrum of RT to 800/427 for all applications |

Wet layup, infusion prepreg. RT, oven and autoclave cure and vacuum press applications. Scale of application ranges from test panels to large scale (i.e., aircraft wings, fuselage, boats and wind blades) |

Silicone, Viton, latex |

0.25" and larger |

16 port types in multiple sizes |

|

|

T-077 80 gsm Nylon fabrics with red tracers |

NP |

FLD 120 25my PP HD low-temp; FLD 170 30my medium/high-temp; FLD HT-500 13my/25my FEP high-temp |

P3 10 mm centers, size 0.5 mm +/- 0.2 mm; P31 5 mm centers, size 0.5 +/- 0.2 mm |

Polyester |

POLY-FLEX TF12 120 gsm 1.3 mm; POLY-FLEX TF15 150 gsm 1.6 mm; POLY-FLEX TF20 gsm, 2.0 mm; and POLY-FLEX TF30 300 gsm 2.7 mm |

N/A |

N/A |

N/A |

N/A |

N/A |

Butyl |

AN-3 Gray, max temp 284/140; AN-3 yellow, max temp 410/210 |

Nylon/polyolefin co-extruded films |

FLM 120 75my low-temp vacuum bag films; FLM 170 50my high-temp vacuum bag films; TBL 170 50my high-temp vacuum tubulars; TBL 170 75my high-temp vacuum tubulars; TBL 200 50my high-temp vacuum tubulars; TBLAD 170 70my high-temp self-releasing vacuum tubulars |

FLM120 for infusion, hand lamination; FLM/TBL 170 for oven and autoclave processes; TBL 200 for oven and autoclave; TBLAD 170 oven and autoclave |

N/A |

N/A |

N/A |

|

|

ATL offers a range of Airtec International brand products for the vacuum bagging and vacuum infusing process, including release films and peel ply, bleeders/breathers, flash and sealant tape, as well as bagging films and other specialty items. Please reference this company's website for specific product details. |

|||||||||||||||||||

|

Polyester, polyamid and adhesive peel ply; peel ply for structural bonding (approved by Airbus and Boeing) |

NP |

284-752°F/120-400°C; perforated or not |

500µ or 800µ diameters; 5-10 mm spacing |

Polyester |

150-440 gsm |

Woven glass and nonwoven polyester fabrics |

N/A |

N/A |

N/A |

Polyester/acrylic; polyester/silicon; PTFE/silicon; polyimid/silicon |

Low-temp sealant tape (infusion process); high-temp (vacuum molding and in/out of autoclave); very high-temp (thermoplastic) |

RT to 752/400 |

Tubular, v-sheet, sheets, kits |

Multilayer bagging film; polyamid film; high-elongation film |

Marine industry (up to 32 m wide); aeronautics; wind energy; sport and leisure |

Marine industry (up to 32 m wide); aeronautics; wind energy; sport and leisure |

50 mm (1.97") and 65 mm (2.56") |

||

|

Econostitch, nylon release, polyester, PTFE-coated fiberglass |

N/A |

Medium-temp copolymer, high-temp fluoropolymer |

N/A |

Polyester |

0.125", 4 oz (~113g) and 7 oz (~198g) |

Nonwoven |

4 oz up to 40 psi; 7 oz up to 85 psi |

N/A |

N/A |

Polyester |

Synthetic rubber |

Up to 400/204 |

Polyethylene, Stretchlon, nylon |

Up to 400/204 |

Films available for low-conform and high-conform applications. Stretchlon 200 Film available in flat 60"-wide sheet, and a 120"-wide sheet. Nylon bagging film suitable for use with temperatures <300°F and usable in variety of styles; nylon bagging film, >300°F available in a 60"-wide flat sheet, which can be heat-seamed to shape requirements or to create larger sheets. |

N/A |

For use with 0.5" tubing |

||

|

Nylon |

High-temp, tough fluropolymer and Teflon |

0.381 mm diameters on staggered, 0.25" centers; 1.143 mm diameters on 2" centers; and 1.143 mm diameters with 3.5" centers |

Polyethyline perforated material and Teflon porous material |

1 and 2 mils |

N/A |

N/A |

N/A |

N/A |

1" and 2" polyester backing |

Dark gray and light gray |

450/232 |

2 mil 60V fold and 30" tube; 5 mil thickness option |

Nylon (5, 10 and full rolls available) |

Aerospace, wind energy, marine, automotive, etc. |

N/A |

0.25" |

|||

|

Lavender CE offers a range of products for the vacuum bagging process, including release films and peel ply, bleeders, breathers, flash and sealant tape, as well as bagging film and vacuum ports. Please reference this company's website for specific product details. |

|||||||||||||||||||

|

Peel Ply A, B and F |

N/A |

FEP and ETFE |

0.015 and 0.045 |

Polyester |

2.2, 4, 10 |

N/A |

N/A |

N/A |

N/A |

Polyester, acrylic |

NA350 |

Up to 400/204 |

Nylon |

Up to 400/204 |

N/A |

N/A |

|||

|

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

PTFE-coated glass fiber breather mesh (variable sizes available) |

Can sustain perfect negative pressure of 13 psi, and withstand temps of nearly 500/260 |

N/A |

N/A |

N/A |

No required |

N/A |

N/A |

N/A |

N/A |

High-strength silicone materials that can sustain perfect negative pressure and withstand temps up to 392/200 |

Vertical and horizontal vacuum ports are offered; 1/4 NPT with/without air hose quick connect |

Minimum of one required, depending on application and/or bag size |

|

|

SWORL reportedly eliminates the need for most of the items mentioned above such as sealant tape, bagging film, breather fabrics, peel ply and release films, bleeders, breathers and flash tape. SWORL is being used in a broad range of intricate and/or high-volume applications such as marine, industrial, architectural, and aerospace applications. SWORL is used in a wide variety of process applications including infusion, oven cures, autoclave cures and as well as OoA and over a wide variety of resins such as prepregs, PE, VE PUR, phenolics, and epoxies. |

Spray silicone |

13 mm (0.512") and 16 mm (0.629") |

Number of ports needed per bag is part dependent |

||||||||||||||||

|

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

PTFE-coated Kevlar screen/belting |

200 psi |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

N/A |

Silicone, rubber, EPDM |

0.25, 0.375 and 0.5" male NPT; 1/4 male BSPT; adapters for JIC, SAE and larger NPT connections |

||

Related Content

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MorePlant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MorePlant tour: Joby Aviation, Marina, Calif., U.S.

As the advanced air mobility market begins to take shape, market leader Joby Aviation works to industrialize composites manufacturing for its first-generation, composites-intensive, all-electric air taxi.

Read More3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MoreRead Next

Vacuum bagging: The basics

A primer on the reasons to use vacuum bagging in composite part manufacture, and the basics of how to do it

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More