Terma Aerostructures: Grenaa, Denmark

This Danish manufacturer of precision composite aircraft parts and components has emerged as a significant player in fabrication of Lockheed Martin’s F-35 Lightning II.

A world leader in the manufacture of precision composite aerostructures and components, Danish defense and aerospace company Terma’s plant in Grenaa, Denmark, Terma Aerostructures, has fabricated aircraft parts for 45 years. Terma worked at first in aluminum and titanium, and, as new technologies were introduced into aerospace, composites and composite-to-metal bonded assemblies. The General Dynamics F-16 fighter was Terma’s first platform for the application of composites. Since then, the company’s composite components have included panels for the AgustaWestland (Casina Costa di Samarate, Italy) AW101 Merlin helicopter, winglets for Gulfstream (Savannah, GA, US) aircraft, wing structures for Airbus (Toulouse, France), and warhead fairings for the RIM-162 Evolved SeaSparrow Missile (ESSM), built by Raytheon (Waltham, MA, US).

Today, parent-company Terma A/S is a key partner and major supplier to the multinational acquisition effort for the F-35 Joint Strike Fighter, for which Lockheed Martin (Bethesda, MA, US) is the prime contractor. That and Terma’s significant history in aerostructural development was a strong determining factor in CW’s acceptance of a recent invitation to visit the Grenaa facility.

CW learned that composites — especially on the F-35 program — are a very important segment of Terma’s overall business thrust. Peter Worsøe, Terma’s VP of business development and CW’s tour guide, told us that although they have had a major influence on the aerospace industry for the past three decades, composites are still, in many ways, a new material. And, he says, despite the fact that the aerospace industry is very big, it’s controlled by a relatively small number of companies — a few hundred worldwide. Worsøe goes on to say that this fact makes the aerospace manufacturing community necessarily interdependent: “Many of these companies are competitors and partners at the same time, depending on the program.” (Programs like the F-35, in fact, are all about such partnerships. See the Side Story titled “Aerospace supply chain partnerships: Offsets vs. opportunities,” under "Editor's Picks" at top right.)

Right people and right materials

The Terma Aerostructures Grenaa plant, on the coast of Jutland in Denmark, covers more than 26,000m2 and has 290+ employees. Another 30 work in design and engineering at Terma’s headquarters in nearby Lystrup. Situated some 30 miles from Aarhus, Denmark’s second largest city, the plant’s location, Worsøe says, makes it challenging to attract highly educated engineers to the site. “But when we get them,” he contends, “they tend to stay. We have a large and reliable group of people working in our workshop, and they are fundamentally the backbone of our company.”

Although composites require special expertise, Worsøe points out that Terma’s relationships to its composite materials suppliers do as well. “There are very few of them,” he observes, noting, “It’s not like in metallic, where you can find hundreds of suppliers and vendors for that kind of product. Our composites supply chain is controlled by our customers. They want to ensure that we have the highest and best-possible quality in our product, so they guide us to the right suppliers, who are mainly American, so the majority of our raw materials comes out of the US.”

Different aircraft also have differing requirements. For instance, the entire F-35 aircraft is digitally designed, which means there are no paper drawings. For the F-35, the requirement is for highly precise components — so precise, in fact, that Terma’s Donny Weaver, VP of business development stationed in Terma’s US aerostructures business unit, who was at the Grenaa facility during the tour, told us, “There are six facilities in the world that do what we do.”

Right products, right properties

Although advanced composites are finding wider military applications on naval vessels — the US Navy’s DDG-1000 Zumwalt-class guided-missile destroyer and Sweden’s Visby-class missile corvettes are notable examples — Worsøe says the fundamental manufacturing principles are similar, but differ markedly in the details for aerostructures. They are at odds, in part, in terms of what motivates design. “We talk about fibers, and we talk about a resin, so that part is the same,” he notes, but observes that the shipbuilding industry’s choice of core materials “will typically be materials that are cheaper per weight unit in order to ensure that the total price of the ship composite fits to that industry. When it comes to the building of aircraft, weight is absolutely essential,” he says, “so we drive the properties of the materials to the limit to ensure that the weight is as low as possible. So when it comes to the detailed quality requirements, we go one step further — or maybe many steps further.” In that regard, Terma makes no accommodations that favor thrift or efficiency in sacrifice of performance when it comes to its molding processes.

Here we are introduced to Robert Fiorentini, Terma’s VP of global operations. Although resin infusion is common practice in shipbuilding and has made some inroads into aircraft manufacturing (see “Resin-infused MS-21 wings and wingbox” under "Editor's Picks"), we’re told, and on the F-35 program, in particular, Fiorentini makes clear that Terma Aerostructures employs autoclave-cured carbon fiber/epoxy and carbon fiber/bismaleimide (BMI), “to make sure there are no voids, so we have consistent structural integrity.”

Although composites reduce part weight, they generally cost more compared to the same part in metal, Fiorentini acknowledges, but says that the cost differential is getting smaller. For that, he gives credit to automation and to the opportunities composites offer for integrating parts.

“An aircraft based on composites can typically end up consisting of fewer and larger, high-precision parts,” agrees Worsøe, adding that parts integration also eliminates labor-intensive post-mold processing: “If they were done in metal, it would require more individual parts, which would require assembly.”

Terma procures its carbon fiber, BMI and epoxy from Cytec Aerospace Materials (Tempe, AZ, US), its NOMEX aramid honeycomb core from Hexcel (Stamford, CT, US) and syntactic core materials from Euro-Composites Corp. (Elkwood, VA, US).

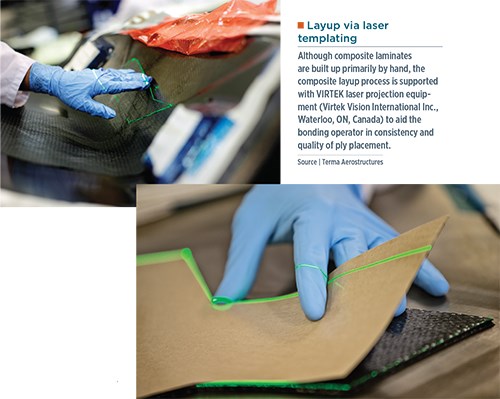

We walk through Terma’s production process. After a visit to the area where plies are cut to precise shapes on an automated textile cutter, we move on to Terma’s cleanroom, where part layup is conducted. Here, the simplest part might have just four plies, while the largest might represent as many as 800. The prepregged fabric can be placed manually or with the aid of a laser projector. Typical layups, we are told, take about eight to nine hours. But, something very complex — a horizontal tailskin, for example — could take as long as two weeks.

Autoclave cure is conducted from 180°C to 190°C, with some post-curing required at even higher temperatures. The autoclaves are calibrated to between +5°C and -2°C, but have a broader temperature range than is currently being used, if required.

To make autoclave cure as efficient as possible, parts are organized into “families” that can be processed and cured together in a single autoclave cycle. Terma has invested in a range of autoclaves, large and small, from Scholz Maschinenbau Scholz GmbH & Co. KG (Coesfeld, Germany). Each is equipped with computer-controlled curing cycles. Working capacities range as large as 3m in diameter by 8m long, with temperature capabilities of 250°C-450°C. Two programmable convection ovens, from Aeroform France(Brignais, France) and Lytzen A/S (Soeberg, Denmark), are also available for curing.

Heat and airflow are critical parameters for the autoclave process. “The local plan is approved by the customer to get the proper cure,” Fiorentini says.

Making composite components requires skill, precision equipment and a little patience. “We’re subcontractors to subcontractors,” Fiorentini says. “There’s a high level of complexity, because different primes have different requirements.”

The processes are approved by the customer using their specified equipment, technical documentation and training. Tools are supplied or specified by the customer, and must be maintained and stored as directed. “We have 310 different customer-provided tools for our F-35 work,” says Fiorentini.

Because Terma makes parts for different companies, each time the autoclave is used, the entire process is digitally recorded to assure quality and ensure adherence to customer specifications. “Each customer has a different process and quality certification, which has legal ramifications,” Fiorentini points out.

Right fit, right function

Although molding and curing are critical to F-35 success, Worsøe says, “the most unique process linked to the F-35 is the trimming process, which has to meet stringent tolerance requirements.” In support of that task, we see as we move on, Terma has invested significantly in machining capability. The Grenaa facility houses two Dörries Scharmann Technologie GmbH (DST) (Mönchengladbach, Germany) flexible overhead gantry (FOG) 5-axis milling machines. One has a work envelope of 4,800 mm by 3,500 mm by 1,500 mm and the other, 2,800 mm by 2,800 mm by 1,500 mm — with Siemens Sinumerik computer numerical control (CNC) by Siemens PLM Software Inc. (Plano, TX, US), which enables CAD drawings to be rendered into 3-D objects.

The facility also has two 5-axis Deckel-Maho precision milling machines: a DMF 360 (3,600 mm by 920 mm by 900 mm), and a DMC200P (1,800 mm by 2,000 mm by 1,100 mm), from DMG Mori Seiki Europe AG(Dübendorf, Switzerland), both controlled by a Heidenhain iTNC 530 PLC (HEIDENHAIN GmbH, Traunreut, Germany). Cutting and grinding is accomplished by a number of tools, including shears, belt and circular saws, and water jet cutters.

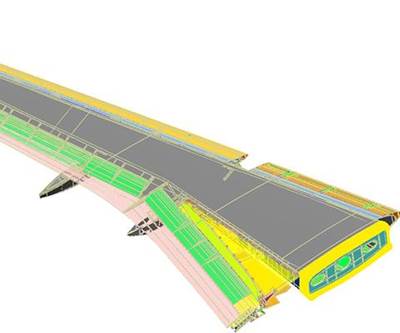

The F-35 has about 300 panels that make up the exterior of the aircraft, and Terma is responsible for 55 of them, of varying sizes, shapes and thicknesses. Fiorentini says flight-control surfaces can have as many as 651 total plies, with maximum stack of 60 plies deep (which equates to 12.7 mm thick, after cure).

Parts used for the skin of the airframe might have as many as 600 precisely drilled holes for fasteners, with tolerances of 0.127 mm. The finishing process includes countersinking parts for fasteners and attachments, and painting parts with the F-35’s distinctive aqueous green primer, using a nonvolatile organic compound.

One advantage of the pursuit of exacting precision is that it’s easier to exchange one component with another because they all fit perfectly. Another is that gaps between parts are so small that aerodynamics are improved. Additionally, the shape, the materials, and tight fit all contribute to low radar observability.

Most parts require secondary bonding, Fiorentini says, which requires careful surface preparation. Both “peel ply” and “grit blasting” techniques are employed. “Prior to cure, we apply a layer of peel ply to the surface area to be bonded in a cleanroom environment. After cure, we go back into the cleanroom and the peel ply is removed. Some parts also require trim or machining — or both — prior to secondary bonding, and these parts undergo a water break-free test and dry-out period prior to secondary bonding. On parts where peel ply is not an option, the parts are subjected to a grit-media blast for surface prep. These parts are cleaned, and a water break test performed to assure there are no contaminants, and then they undergo a dry-out period prior to secondary bonding.”

Right instruments, right outcomes

Given the F-35 program’s high expectation for precision and precision’s role in the plane’s aerodynamic performance, it’s no surprise that the Terma Aerostructures tour terminates in the facility’s quality-assurance area. Here, nondestructive inspection methodologies include not only aerospace-standard ultrasonic equipment but also X-ray technology. Terma, we are told, is the only supplier on the F-35 program that is approved to use digital X-ray for inspection of parts and pioneered the process in partnership with Lockheed Martin. “Digital X-ray reduces the inspection time by 75% and is more accurate that A-Scan, which is a more manual process,” Fiorentini claims. Ultrasonic testing equipment includes a Karl Deutsch GmbH (Wuppertal, Germany) Echograph model 1030 ultrasonic flaw detector, and ultrasonic testing is also accomplished with 2- and 5-axis ultrasonic units for monolithic parts, including a Meccasonics Ltd. (Ross-on-Wye, UK) USJP-1 and USL Multi-Axis C-Scanner, and a Balteau X-Ray nondestructive testing and condition monitoring device, from Balteau NDT S.A. (Hermalle-sous-Argenteau, Belgium).

Right perspective … more opportunities

Terma still makes metal parts for aircraft. “We do advanced machining of metallic parts, such as 5-axis machining, and concentrate on the most complex parts, and outsource the less complex parts to someone with lower costs,” notes Fiorentini. However, there are no sheet metal parts in the F-35. Worsøe says Terma is focused on today’s F-35 work, but with an eye on the future, too. “We hope to have the opportunity to participate in modern high-rate production programs — military and commercial — that brings down our learning curve, and can justify implementation of automatic manufacturing procedures.”

“We have unique expertise,” Weaver sums up. “And we have space to add capacity as the F-35 ramps up.”

Related Content

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MoreNext-generation airship design enabled by modern composites

LTA Research’s proof-of-concept Pathfinder 1 modernizes a fully rigid airship design with a largely carbon fiber composite frame. R&D has already begun on higher volume, more automated manufacturing for the future.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Resin-infused MS-21 wings and wingbox

Moscow-based aeromanufacturer uses out-of-autoclave composites in attempt to leapfrog Airbus and Boeing with wider, lighter, more efficient single-aisle airliner.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More

.jpg;maxWidth=300;quality=90)