Syensqo

Composites House, Sinclair Close,

Heanor Gate Industrial Estate,

Heanor, Derbyshire DE75 7SP GB

770-772-8200

custinfo@solvay.com

solvay.com

About Syensqo

IS THIS YOUR COMPANY?

As Seen On CompositesWorld

Syensqo Supplies the Following Products

- Adhesive bonding

- Armor, composite

- Autoclave cure

- Backup structures

- Bismaleimide (BMI)

- Bismaleimide, >12K tow

- Bismaleimide, 12-inch tape

- Bismaleimide, 3-inch tape

- Bismaleimide, 6-inch tape

- Bleeder cloths

- Breather cloths

- CAD/CAM/CAE design

- Carbon fiber composite

- Caul plates

- Compression molding

- Consulting, materials

- Cyanate ester

- Cyanate ester, <12K tow

- Cyanate ester, >12K tow

- Cyanate ester, 12-inch tape

- Cyanate ester, 3-inch tape

- Cyanate ester, 6-inch tape

- Education/Training

- Epoxy, <12K tow

- Epoxy, >12K tow

- Epoxy, 12-inch tape

- Epoxy, 250 F cure

- Epoxy, 250 F cure, <12K tow

- Epoxy, 250 F cure, >12K tow

- Epoxy, 250 F cure, 12-inch tape

- Epoxy, 250 F cure, 3-inch tape

- Epoxy, 250 F cure, 6-inch tape

- Epoxy, 3-inch tape

- Epoxy, 350 F cure

- Epoxy, 350 F cure, <12K tow

- Epoxy, 350 F cure, >12K tow

- Epoxy, 350 F cure, 12-inch tape

- Epoxy, 350 F cure, 3-inch tape

- Epoxy, 350 F cure, 6-inch tape

- Epoxy, 6-inch tape

- Epoxy, Film

- Epoxy, Foam

- Epoxy, Hot melt

- Epoxy, Paste

- Epoxy, toughened

- Epoxy, toughened, <12K tow

- Epoxy, toughened, >12K tow

- Epoxy, toughened, 12-inch tape

- Epoxy, toughened, 3-inch tape

- Epoxy, toughened, 6-inch tape

- Film and sheet

- Hoses, pressure

- Hoses, vacuum

- Infrastructure, composite

- Inserts

- Laminate panels, with core

- Laminate sheets, solid

- Master pattern material, other

- Master pattern material, polymeric

- Materials analysis

- Other composite structures

- Other, <12K tow

- Other, >12K tow

- Other, 12-inch tape

- Other, 3-inch tape

- Other, 6-inch tape

- Peel plies

- Peel plies, nylon

- Peel plies, polyester

- Phenolic

- Phenolic, <12K tow

- Phenolic, >12K tow

- Phenolic, 12-inch tape

- Phenolic, 3-inch tape

- Phenolic, 6-inch tape

- Polyester, unsaturated, <12K tow

- Polyester, unsaturated, >12K tow

- Polyester, unsaturated, 12-inch tape

- Polyester, unsaturated, 3-inch tape

- Polyester, unsaturated, 6-inch tape

- Polyether ketone family (PAEK, PEKK, PEEK)

- Polyimide, <12K tow

- Polyimide, >12K tow

- Polyimide, 12-inch tape

- Polyimide, 3-inch tape

- Polyimide, 6-inch tape

- Product design

- Release papers, coated

- Repair services, composites

- Sealing tapes and materials

- Shrink film

- Shrink tapes

- Testing, materials

- Testing, product

- Tooling prepreg

- Tubes

- Vacuum bagging materials, nylon

- Vacuum bagging materials, other

- Vacuum bagging materials, polymide

- Vacuum bagging materials, reusable

- Vacuum bagging materials, silicone

- Vacuum valves and pumps

- Vinyl ester, <12K tow

- Vinyl ester, >12K tow

- Vinyl ester, 12-inch tape

- Vinyl ester, 3-inch tape

- Vinyl ester, 6-inch tape

Editorial, News, and Products

-

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

-

Altair announces 12th annual Enlighten Award winners

Companies like Syensqo, Weav3D, Toyota, CompositeEdge and Teijin Automotive Technologies are recognized for their composites-forward approaches to more sustainable, energy-efficient automotive efforts.

-

Syensqo, Orbex to enhance space launch system development

The partnership will drive advancements in performance, durability and reuse of orbital space launch systems integrated with Syensqo’s adhesive, composite and specialty polymer materials.

-

AZL announces follow-up projects on electromobility casings, thermal runaway

AZL continues series of projects to develop the next generation of battery casings for electromobility, encourages interested companies to join consortias before Sept. 11th kick-off.

-

Syensqo provides PARA resin for Artiphon musical instrument

Artiphon has chosen Syensqo’s Ixef PARA fiber-filled resin in the production of Chorda, its custom handheld electronic musical instrument.

-

Aernnova Composites, leader in composites R&D

This sidebar to CW’s July 2024 feature article reviews the company’s achievements and capabilities through years of composites R&D programs.

-

Composites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

-

From the CW Archives: Fast-cure epoxies for automotive fabrication

Sara Black’s 2015 report on the development of snap-cure epoxies for automotive manufacturing still resonates today.

-

Syensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

-

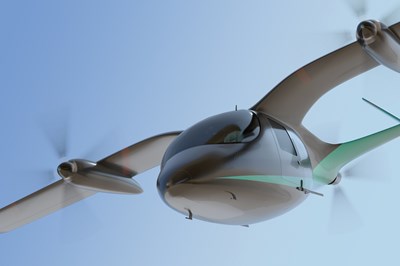

Upcoming CW Tech Days navigates composites in AAM

Don’t miss the Dec. 7th “CW Tech Days: Composites in advanced air mobility,” from 11 a.m. to 3:30 p.m., where materials suppliers and OEMS will discuss challenges and provide insight to better prep the composites industry for the AAM market’s demands.

-

Solvay partners with iCOMAT for tow steering technology

Solvay’s partnership with iCOMAT will accelerate the commercialization of its rapid tape shearing technology for high-volume composite part production.

-

Solvay releases SolvaLite grade to mitigate BEV thermal runaway

Fast-curing epoxy prepreg grade protects electric batteries from fire hazards, outperforming aluminum and discontinuous fiber composites in practical UL 2596 flammability tests.

-

Solvay expands range of FusePly covalent bonding for composite structures

FusePly 250 technology, designed for 250°F to 350°F composite bonding, offers optimized bond reliability and high part performance.

-

Solvay carbon footprint tool accelerates GHG reduction efforts

The digital tool will enable Solvay to quickly and accurately calculate the carbon footprints of its products and take action to reduce them, beginning with its Novecare sites and extending to other business areas.

-

Solvay launches Xencor XTreme for battery thermal runaway protection

Long glass fiber-reinforced PPA solution, produced with partially bio-based content, provides resistance to thermal runaway and propagation in EVs.

-

Solvay becomes Beta Technologies material supplier for AAM

Beta Technologies’ electric CTOL and VTOL aircraft will use lightweight composite materials to enable zero-emission passenger and cargo air transit.

-

Next-gen composites manufacturing: Combining material, machine and mold cavity data with analytics

Using a sensor, an edge device and machine learning software, sensXPERT sees into processes and is improving quality and cutting scrap, cycle time and energy use for composites customers like ZF and Carbon Revolution.

-

Plant tour: Spirit AeroSystems, Belfast, Northern Ireland, U.K.

Purpose-built facility employs resin transfer infusion (RTI) and assembly technology to manufacture today’s composite A220 wings, and prepares for future new programs and production ramp-ups.

-

Solvay, Ascendance Flight Technologies and Airborne join forces

Strategic collaboration agreement will see to the development of innovative advanced materials and aerospace technologies that will enhance the safety, efficiency and sustainability of future aircraft.

-

Solvay, Spirit collaborate to accelerate composites adoption

Solvay and Spirit AeroSystems have cemented their research and technology relationship on the development of composite aerostructures, to take place in Prestwick, Scotland.

-

JEC World 2023 highlights: Innovative prepregs, bio-resins, automation, business development

CW’s Jeff Sloan checks in with JEC innovations from Solvay, A&P, Nikkiso, Voith, Hexcel, KraussMaffei, FILL, Web Industries, Sicomin, Bakelite Synthetics, Westlake Epoxy and Reliance Industries.

-

Solvay and Syensqo revealed as new company names

Solvay is splitting its business with the company’s composite materials segment assuming the Syensqo name.

-

Solvay opens new Application Development Laboratory in China

State-of-the-art facility responds to growing customer demand for tailored solutions with high-performance materials in China.

-

Solvay, GKN Aerospace renew collaboration agreement

Both companies aim to expand the use of thermoplastic composite materials on high-rate aerospace structures.

-

JEC World 2023 preview

JEC World is the composites industry’s largest trade event, featuring exhibits, presentations and specialized pavilions covering the entire composites industry supply chain.

-

Solvay features Xydar polymer for high-heat EV battery module insulation

Xydar LCP G-330 HH is a new glass-filled liquid crystal polymer grade designed to increase passengers’ safety in the event of battery thermal runaway.

-

MFFD thermoplastic floor beams — OOA consolidation for next-gen TPC aerostructures

GKN Fokker and Mikrosam develop AFP for the Multifunctional Fuselage Demonstrator’s floor beams and OOA consolidation of 6-meter spars for TPC rudders, elevators and tails.

-

NASA awardees to develop sustainable aviation composite tech

Fourteen Advanced Composites Consortium organizations support the evaluation and development of next-gen thermosets, resin-infused composites and thermoplastics at small scales.

-

CW presents "CW Tech Days: Thermoplastics for large structures"

Attend this May 18th interactive webinar sponsored by Altair, Mitsubishi Chemical Group, Toray and Collins Aerospace which will explore the materials and processing technologies that are enabling the transition into thermoplastics.

-

PEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

-

Solvay, Airborne receive funding for composite battery enclosures

Collaboration is targeted at maximizing the energy capacity of lightweight and compact next-generation battery packs for e-mobility, while also targeting reuse of composite waste.

-

Bio-based acrylonitrile for carbon fiber manufacture

The quest for a sustainable source of acrylonitrile for carbon fiber manufacture has made the leap from the lab to the market.

-

ASCEND program update: Designing next-gen, high-rate auto and aerospace composites

GKN Aerospace, McLaren Automotive and U.K.-based partners share goals and progress aiming at high-rate, Industry 4.0-enabled, sustainable materials and processes.

-

Composites opportunities in eVTOLs

As eVTOL OEMs seek to advance program certification, production scale-up and lightweighting, AAM’s penetration into the composites market is moving on an upward trajectory.

-

High-temperature composite 3D printing facilitates design, manufacture of deployable space structures

Opterus R&D employs an AON3D printer and OOA prepregs to build the tooling, prototypes and end-use versions of its foldable CFRP satellite structures.

-

Composites end markets: Aerospace (2023)

With COVID in the past and passengers flying again, commercial aircraft production is ramping up. The aerocomposites supply chain is busy developing new M&P for an approaching next-generation aircraft program.

-

Trillium awarded DOE funding for bio-based acrylonitrile demonstration plant

New award will enable Trillium and its project partners Solvay, Koch Modular and Matric to demonstrate sustainable production of acrylonitrile at scale for use in various material applications like carbon fiber.

-

People in Composites: November 2022

New hires, appointments and changes in executive leadership have been announced by Wickert, Michelman, Altair, Fortify, KraussMaffei and the Aerospace Industries Association (AIA).

-

One-piece, one-shot, 17-meter wing spar for high-rate aircraft manufacture

GKN Aerospace has spent the last five years developing materials strategies and resin transfer molding (RTM) for an aircraft trailing edge wing spar for the Airbus Wing of Tomorrow program.

-

Plyable secures $3.2 million investment to advance custom composite marketplace solution

Funding from Maven Capital Partners, Solvay Ventures and VC Forward Partners backs growth of time- and cost-saving digital composite tooling product.

-

Solvay-NIAR Manufacturing Innovation Center opens

Partnership is dedicated to enabling increased efficiencies and performance in aviation through advances in composites technologies.

-

CAMX 2022 exhibit preview: Solvay

Fast-curing epoxy surfacing film SolvaLite SF200 generates a smooth surface and Class-A finish desired in composite automotive applications.

-

Thermoplastic composites welding advances for more sustainable airframes

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

-

Solvay launches LTM 350 low-temperature composite tooling prepreg

Carbon fiber epoxy prepreg sets new standards in cost-efficient composite tooling with fast layup, fast initial cure and short post-cure cycles.

-

Mass, cost, durability improvements: EV battery enclosures, Part 2

As interest grows in composite battery covers and trays, composite materials suppliers work to meet current and future needs of automakers, battery module producers.

-

COMAC reports C919 flight testing is complete

Seven C919s have been built and flown to date, with test flights at four locations across China. Composites continue to be key elements for the nacelle system, aircraft tail and more.

-

Solvay reports positive first half 2022 results

Strong financial results are reported with net sales and record underlying EBITDA up +32.6% and 35% organically, respectively, contributed by Solutions, Materials and Chemicals segments.

-

High-performance, high-detail continuous 3D-printed carbon fiber parts

Since 2014, Mantis Composites has built its customer and R&D capabilities specifically toward design, printing and postprocessing of highly engineered aerospace and defense parts.

-

Plant tour: National Institute for Aviation Research, Wichita, Kan., U.S.

NIAR, located at Wichita State University in the heart of the American aerospace manufacturing industry, has evolved to become a premier hub of teaching, R&D, creativity and innovation.

-

Materials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

-

Materials & Processes: Fabrication methods

There are numerous methods for fabricating composite components. Selection of a method for a particular part, therefore, will depend on the materials, the part design and end-use or application. Here's a guide to selection.

-

Solvay supports record-holding athletes in Paris 2024 Paralympic Games

The Solvay 4 Sport partnership aligns with the group’s DEI program, which aims to cultivate an equitable and inclusive environment that embraces diversity.

-

Impressions and takeaways from JEC World 2022

Suffice to say that JEC World 2022, the “Big Show” for the composites industry, exceeded many expectations. Dale Brosius contemplates pervasive themes, conversations and takeaways from the international event.

-

JEC World 2022, Part 3: Emphasizing emerging markets, thermoplastics and carbon fiber

CW editor-in-chief Jeff Sloan identifies companies exhibiting at JEC World 2022 that are advancing both materials and technologies for the growing AAM, hydrogen, automotive and sustainability markets.

-

Digital design, multi-material structures enable a quieter supersonic NASA X-plane

NASA’s composites-intensive X-59 QueSST experimental aircraft is set for its first flight by the end of 2022, after nine years of design, manufacture, assembly and testing by Lockheed Martin Skunk Works.

-

3A Composites Core Materials acquires Solvay’s TegraCore foam

PPSU thermoplastic foam with enhanced fire-retardant properties to be targeted for the aerospace, marine and rail markets.

-

High-performance sustainability and cost-efficiency advance with HiPerDiF

In the latest chapter of the HiPerDiF (High Performance Discontinuous Fibre) story, commercial production is on the near horizon for high-performance composite materials that are both sustainable and formable, leading to simpler, more cost-efficient composites manufacturing.

-

First production Comac C919 narrowbody completes maiden flight, price higher than expected

China’s first narrowbody to compete with Boeing 737 and Airbus A320, the C919 nears entry into service and uses composites in common secondary structures.

-

Solvay expands Solvalite portfolio into automotive, invest in Xencor LFT production facilities

New fast curing carbon fiber and woven fabric prepregs target high-volume automotive applications such as body panels with optimized structural part performance.

-

SuCoHS project: Advancing composite solutions for parts with high thermal and mechanical loads

New materials, structural concepts and manufacturing using sensors for composites that resist fire, temperature and loads while providing weight and cost savings versus metals.

-

Aerovac Composites One announces Argosy International as distribution partner in Asia

Exclusive distribution of specialty composite materials and services will serve markets in China, Taiwan, South Korea, Malaysia, Thailand, Singapore, Indonesia, Vietnam and the Philippines.

-

Solvay explores a separation into two independent publicly listed companies

Split into EssentialCo and SpecialtyCo — the latter of which comprises the Materials, Specialty Polymers, Composites and Solutions segments — Solvay seeks to unlock value, sharpen strategic focus, optimize growth opportunities and build the foundation for the future.

-

Sensors: Data for next-gen composites manufacturing

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

-

National Composites Center and Meggitt demonstrate linear dielectric sensor for liquid composites processing

Research at Cranfield University is further developed via RTM part trials in NCC’s Technology Pull-Through Program

-

Leonardo, Vertical Aerospace to jointly develop VX4 eVTOL carbon fiber fuselage

Leonardo lends its composite aerostructures expertise, honed on numerous civil and defense aerospace programs, for initial six certification aircraft.

-

NIAR-WSU, Victrex begin NCAMP materials and process qualification for AFP

In-depth investigation into AFP machine variability on composite allowables begins on carbon fiber-reinforced thermoplastic (CFRTP) test panels to achieve certification framework.

-

NASA Institute develops carbon nanotube-based composites for Mars spacecraft

The five-year project employs computational modeling techniques to build composite panels that are three times stiffer and stronger than current carbon fiber to enable manned missions to Mars.

-

The outlook for thermoplastic composites: CW Trending Episode 7

What are the experts saying about the state of thermoplastic composite materials today? CompositesWorld Editor-in-Chief Jeff Sloan dives into this topic and more with Solvay in our latest CW Trending episode.

-

Solvay collaborates with Trillium on bio-based acrylonitrile for carbon fiber applications

New agreement with Trillium Renewable Chemicals will enable Solvay's development of sustainable, bio-carbon fiber for use in various applications.

-

Biesterfeld to distribute Solvay composite materials portfolio across continental Europe

New partnership gives Biesterfeld access to Solvay’s portfolio of composite prepregs, adhesive films, adhesives and primers for aerospace and automotive, as well as technical assistance.

-

Solvay to supply advanced composites, adhesives for space exploration

Ablative material, RTM resins and adhesives will be applied to a range of ESA space programs, including Avio’s Vega family of satellite launch vehicles.

-

Hengshen to produce rear pressure bulkhead demonstrators

China-based Hengshen Carbon and Composites will produce five 4.5-meter demonstrator composite rear pressure bulkheads (RPB) for a Chinese aerospace OEM.

-

The outlook for carbon fiber supply and demand

The picture painted at Carbon Fiber 2021 concerning the current supply and demand for carbon fiber indicates an in-flux, rapidly changing environment across a majority of end markets.

-

Fraunhofer IPT develops thermoplastic composites in hydrogen storage, engine blades and more

Active in laser-assisted tape winding and in-situ consolidation of thermoplastic composites since 1988, the IPT in Aachen, Germany continues to push new materials, applications and Composites 4.0 digital processing.

-

Plant tour: ATC Manufacturing, Post Falls, Idaho, U.S.

ATC is at the top of the list when it comes to thermoplastic composites and aerostructures manufacturing. CW explains why.

-

Solvay, 9T Labs bring additive manufacturing of CFRP parts to mass production

Solvay’s high-performance composite materials, plus 9T Labs’ hybrid additive Red Series solution reportedly process lower production costs for advanced composite parts.

-

Designing for automated composites manufacturing of low-volume aerostructures

The commercial aerospace industry is heavily focused on design for efficient high-rate manufacturing, but there is still need for automated, affordable fabrication of low-rate aerostructures.

-

Vertical Aerospace partners with GKN Aerospace on wing structure for VA-X4 eVTOL

GKN will deliver wing structures and wiring systems for the composites-intensive, zero-emissions aircraft.

-

Solvay completes South Carolina facility installation, adds to U.S. thermoplastic composite capacity

Facility development is fueled by increasing energy, aerospace and automotive demand, and will manufacture UD PVDF, PPS and PEEK tapes.

-

Georgia Tech leads effort to tackle the composite and hybrid materials challenge

New National Science Foundation (NSF) center combines industry and academia, uses analytics, AI to modernize how manufacturers repair composites.

-

Multifunctional composite structures across end markets

Innovators find new ways to add functions — from anti-icing to 5G signal transmission to structural batteries and beyond — into structural composites.

-

Integrating antennas into composite aerostructures

ACASIAS project integrates Ku-band array antenna in novel AFP orthogrid with drastically reduced tooling for more fuel-efficient, multifunctional CFRP aircraft fuselage panel.

-

People in Composites: June 2021

CW’s monthly roundup of people news in the composites industry this month includes CTC, Engineering Technology Corp., Solvay, Vestas, Teton Simulation, Michelman, Boston Materials and Astro Aerospace.

-

Speeding RTM with heat-flux sensors

Clean Sky 2 INNOTOOL 4.0 project advances cure monitoring for larger and less costly lightweight landing gear made using composites.

-

Solvay supplies composites, adhesives, technical support to Novotech Seagull aircraft development

Solvay supports the composites-intensive UAM platform with its aerospace-qualified MTM 45-1 and CYCOM 5320-1 resin systems in preparation for a flight in late 2021.

-

Solvay launches adhesive and surfacing technologies for the aerospace industry

New AeroPaste and BR 179 adhesive and surfacing technologies are expected to increase part assembly, processing efficiency for aerospace manufacturers.

-

Solvay joins the Canadian Advanced Air Mobility Consortium

Solvay supports Canada in its early adoption of advanced air mobility and CAAM’s 2040 long-term goal that one in five aircraft operating in Canada are emission-free.

-

Wing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

-

Composites One to acquire Solvay Process Materials business

The acquired business, rebranded as Aerovac, will act as manufacturer, developer and supplier of process materials, tooling and services and is comprised of a range of vacuum bagging materials.

-

Solvay, Vertical Aerospace expand on UAM agreement

Composite materials supplier Solvay Composite Materials and urban air mobility (UAM) manufacturer Vertical Aerospace offer details about materials, process use in VA-1X aircraft.

-

Hot drape forming

Heat, vacuum and/or pressure advance from debulking prepreg layups to automated preforming of dry reinforcements for faster composites production.

-

Solvay to develop composite structure for Vertical Aerospace eVTOL aircraft

Composite and adhesive technologies will be supplied to Vertical Aerospace for a zero-emissions, all-electric prototype scheduled for a September 2021 test flight.

-

Solvay, Leonardo launch joint research lab for thermoplastic composites

The Solvay Leonardo Joint Research Lab aims to facilitate the broader adoption of thermoplastic composites by the aerospace industry.

-

Composites design helps nano-sized lunar rover hit big milestones

Developed by Carnegie Mellon University, the ultralight, composites-intensive Iris nano-rover will make its lunar debut later this year.

-

Solvay, Composites One enter Process Materials business negotiation

The PM business provides a broad array of vacuum bagging materials. The proposed transaction will enable Solvay to continue focusing on its core composites technology portfolio.

-

Solvay and Boeing sign long-term enterprise agreement

Solvay’s contract extension covers composites and adhesives across all Boeing commercial and defense aircraft programs.

-

Episode 34: Carmelo Lo Faro, Solvay Composite Materials

Carmelo Lo Faro, president of Solvay Composite Materials, talks about how he sees aerocomposites evolving in the time of COVID-19, the rise of computational power to evolve composites use, the prospects for increased composites use in the automotive market, and the increasing importance of education in the composites industry.

-

New 3dpbm market analysis division presents AM industry study results

Analysis of composites additive manufacturing performed by the new market analysis and consultancy group shows the market generating $10.6 billion in yearly revenues by 2030.

-

Solvay, Flybotix collaborate on inspection drone

Solvay's ultra-lightweight and robust thermoplastic carbon fiber composites contribute to doubling the Asio drone’s flight time.

-

Solvay, Lockheed Martin continue F-35 aircraft partnership

The new five-year contract with Lockheed Martin builds on Solvay’s F-35 program commitment to provide high-performance materials and the company’s leadership in composite and adhesive technologies.

-

Update: Lower wing skin, Wing of Tomorrow

Airbus is evaluating several advanced composites technologies as part of its Wing of Tomorrow program. Among these is liquid resin infusion of the lower wing skin, being developed by Spirit AeroSystems.

-

Composites-intensive masterwork: 2020 Corvette, Part 2

Innovative composite materials trim mass, costs and noise on the high-volume mid-engine sports car.

-

Strata, Solvay joint venture facility completed

The 8,500-square-meter United Arab Emirates facility will supply carbon fiber prepreg to Boeing for primary structures on the 777X program.

-

Composites suppliers, fabricators respond to coronavirus

Companies across the composites industry supply chain share how the COVID-19 pandemic is affecting their businesses, and how they are available to help.

-

Solvay implements cost-cutting, efficiency plans

Effciency plans begun for Solvay’s composites business in 2019 are being accelerated to combat loss of business cause by the coronavirus pandemic.

-

Revolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

-

RAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

-

Novel prepreg for compression molding in RAPM

Solvay and Boeing combine aerospace performance with process knowledge for high-rate, low-cost composites production.

-

Transparency Market Research releases Aerospace Composites Market report

Findings predict the global aerospace composites market value and trends between 2016 and 2024.

-

Solvay, Honda sign exclusive supply agreement for business jet programs

Solvay will supply prepreg and lightning strike protection surfacing film for Honda aircraft business jet HA-420 and Elite programs through 2027.

-

Proving out LM PAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test Toray LM PAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

-

People in Composites: February 2020

Solvay, SGL Carbon, Teijin, Gurit, Composites UK and American Colors Inc. announce new hires and retirements in the composites industry.

-

Solvay launches epoxy prepreg for aerostructures compression molding

Solvay Composite Materials has launched CYCOM EP2750, a new highly drapable epoxy prepreg designed specifically for the compression molding of high-quality, high-rate, cost-effective primary and secondary aerostructures.

-

Solvay showcases low-cost prepreg and parts approach using Cygnet Texkimp filament winder

High-speed, tailored preforms are used with Solvay double diaphragm forming (DDF) and compression molding to produce cost-effective, medium-volume auto and aero parts.

-

Carbon fiber suppliers gear up for next-gen growth

CompositesWorld’s annual Carbon Fiber conference was held in Knoxville, Tenn., U.S., in late 2019 and included a pre-conference seminar focused on carbon fiber supply and demand.

-

Plant Tour: RUAG Space, Decatur, Alabama, U.S.

Out-of-autoclave composites manufacturing facility comes of age with first U.S.-made composite structures for the Atlas V launcher, and qualification parts for the Vulcan.

-

Solvay unveils Double Diaphragm Forming automated demonstrator line

The automated line at Solvay's Heanor, U.K. facility combines with the company's fast curing technologies for a 3-minute takt time on cured parts.

-

Solvay, SGL to develop large-tow carbon fiber materials for aerostructures

The joint development agreement (JDA) intends to bring to market the first composite materials for commercial aerostructures based on large-tow intermediate modulus (IM) carbon fiber.

-

Solvay, Penso collaborate on industrialized production of lightweight structures

The FLAVA automotive project has developed composite technologies for creation of a modular, multi-material body-in-white structure for large production volumes.

-

Solvay joins TPRC as Tier 1 member

Solvay’s new thermoplastic composites centers in the U.S. and Belgium will work closely with the ThermoPlastic Composites Research Center on collaborative research.

-

Solvay, Baker Hughes to expand use of thermoplastic composites in oil and gas pipes

Solvay and oilfield equipment company Baker Hughes plan to implement thermoplastic composite materials in offshore flexible pipes and risers.

-

Solvay opens thermoplastic composite centers in U.S. and Belgium

In addition to two new centers, Solvay has signed an agreement with Lockheed Martin and several Belgian companies to grow aerospace composites in Belgium.

-

Bombardier wins award for resin transfer infusion wing

The MacRobert Award 2019 recognizes reduction in parts, fasteners and weight using pioneering advanced composites technology.

-

Continuous fiber-reinforced thermoplastics data added to CAMPUS database

The new data, which will be released in October, is the result of an ongoing material standardization and characterization effort led by German reinforced plastics company AVK.

-

Solvay expands thermoplastic composites manufacturing capacity

Solvay is building a new thermoplastic tape production line at its Anaheim, Calif., facility, underscoring its focus on thermoplastic composites for aerospace.

-

Thermoplastic primary aerostructures take another step forward

Employing new manufacturing techniques and the design freedom they create, GKN Fokker has joined forces with Gulfstream to assess thermoplastic composites for primary aircraft structures.

-

2019 Paris Air Show: Highlights

The 2019 Paris Air Show may have lacked the glamour of a new aircraft program announcement, but the composites industry represented is clearly gearing up for next-generation aerospace manufacturing.

-

SAMPE 2019: The highlights

CompositesWorld was at SAMPE 2019 and offers a summary of highlights from the show and conference.

-

Large, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

-

Solvay epoxy-based film for prepregs

Solvay Composite Materials has developed FusePly, an epoxy-based film that is designed to co-cure with a prepreg and provide a chemically active surface that reacts with functional groups in adhesives to create a covalently bonded structure.

-

Thermoplastic composites: Poised to step forward

The evolving role of thermoplastic materials and processes and their future in next-generation commercial aircraft.

-

DARPA presents TFF program for low-cost composites for defense

Results reviewed at SAMPE 2019 show new materials and side-by-side comparisons of thermoset, thermoplastic, HP-RTM and press-forming, including PtFS molding cell.

-

Solvay, Stratasys partner for additive manufacturing

The companies will develop an aerospace-grade polymer for use with Stratasys 3D printers.

-

Solvay, Safran sign agreement on high-temperature technologies

Safran will use Solvay’s high-temperature advanced materials on critical engine components.

-

Solvay composites selected for racing catamaran

Solvay’s VTM-264 prepreg will be used for structural parts and wingsail of a new catamaran from Spanish manufacturer Balance Aquitectural Naval.

-

Hybrid resin system: Epoxy benefits, without the epoxy

Rapid cure, zero tack material ideal for automated, higher-volume production.

-

Proving viability of dry fabrics, infusion for large aerostructures

Danobat’s ADMP is used to produce a wing demonstrator with non-crimp fabrics.

-

Research of developing coal, oil into low-cost carbon fiber advances

Western Research Institute and academic and industry partners advance into the second year of a research project to turn coal, crude oil and biomass into low-cost carbon fiber.

-

JEC World 2019 briefs

JEC briefs on Bindatex, FILL, Solvay, Henkel, Web Industries, Cobra, PolyOne, GKN Fokker, Thomas Technik + Innovation and Hyosung Advanced Materials.

-

Solvay and Airborne to partner on developing automated processing for composite materials

The partnership aims to identify solutions to the industrialization challenges facing the composites industry.

-

Solvay launches release film for wind industry, displays thermoplastic auto component

At JEC World 2019, Solvay jointly displayed a thermoplastic composite steering knuckle and launched VAC-PERF A2400, a next-generation release film for the wind industry.

-

Composites One to distribute Solvay process materials and tooling products

Solvay has appointed Composites One as a new North America distributor for its process materials and tooling product lines.

-

Leveraging composites for space tourism

Virgin Galactic’s WhiteKnightTwo will carry its SpaceShipTwo to launch position, then rocket passengers to suborbital space for a heavenly view of Earth.

-

HEATCON to partner with Solvay, expand composite material offerings

The partnership focuses on a variety of consumable products used during the repair process of aircraft composite parts.

-

IRG CosiMo thermoplastic composites consortium unveils new facilities

IRG CosiMo combines companies along the whole thermoplastic composites process chain from materials to processing machinery to applications in automotive and aerospace.

-

Solvay opens structural adhesives manufacturing center in the UK

The new center is equipped with cutting edge technologies and industrializes manufacturing capabilities of structural adhesive and surfacing materials.

-

Solvay and Bell sign composites and adhesives supply agreement

Solvay will supply Bell with a portfolio of structural composites and adhesives to be used across military and commercial rotorcraft programs.

-

Solvay awarded GA-ASI Supplier Excellence Award

General Atomics Aeronautical Systems Inc. has recognized Solvay for its work supplying composite technologies for advanced aircraft and defense systems.

-

Heatshield for Extreme Entry Environment Technology (HEEET): A broader mission

3D woven fabric enables scalable, tailorable heatshield that cuts cost, boosts performance for future spacecraft.

-

Safe cycling: Keys to composite bike design integrity

Steps bike designers and manufacturers must take to keep high-performance carbon fiber bikes safe, upright and on the road or trial.

-

Thermoplastic composites consortium aims for high volume production for Automotive and Aerospace

Solvay, Premium AEROTEC and Faurecia Clean Mobility are launching a consortium focusing on high volume production of thermoplastic composites.

-

Infused wing sheds light on aerocomposites future

In the Irkut MS-21 infused and co-cured wings, the aerocomposites industry gets a glimpse of how out-of-autoclave technologies might be applied to primary aircraft structures.

-

Solvay expands with new Texas-based aerospace composites manufacturing facility

The company recently broke ground on a Greenville, TX, US manufacturing footprint expansion that increases the site’s resin mixing capacity.

-

Solvay and Safran sign LEAP aircraft engine supply agreement

Solvay will supply Safran with composite material technologies to manufacture the engine’s critical structural components.

-

Solvay and Airbus extend composite and auxiliary materials contract

The two companies have signed a contract extension until 2025 for the supply of advanced materials.

-

Solvay and Spirit AeroSystems extend composite materials supply agreement

The two companies have signed an extension to their supply agreement for composites and adhesives to be used on nacelle and fuselage applications across Boeing’s commercial programs.

-

Plant tour: Israel Aerospace Industries, Ben Gurion International Airport, Israel

Israel Aerospace Industries (IAI) is developing increasing expertise both in and out of the autoclave as it expands an already broad composites production portfolio.

-

Solvay assumes direct service of its composite materials business in the Asia Pacific Region

Specialty material distributor Argosy and Solvay sign agreement to transition advanced materials business.

-

SAMPE 2018 new products target next-generation aircraft

The broader aerospace world might be patiently waiting for Boeing to officially announce plans to develop its New Middle-Market Airplane (NMA, or 797), tabbed as a replacement for the 757, but suppliers aren’t sitting on their hands.

-

SAMPE 2018 keynote looks to the composites future

The SAMPE 2018 general session featured the announcement of the top three papers presented at the conference, and a keynote by Carmelo Lo Faro, president, Solvay Composite Materials (Alpharetta, FA, US).

-

Solvay and RUAG join forces to supply next-generation space launcher programs

Solvay has signed a new agreement to supply RUAG with advanced structural composites for US and European space launcher programs.

-

Solvay launches FusePly aerospace composite bonding technology

FusePly enables the build of bonded composite parts using conventional manufacturing processes, through the creation of covalently bonded structures.

-

Solvay and MultiMechanics partner on material simulation software

New material simulation software platform could reduce the time and cost of developing and certifying new composite materials by 40%.

-

Solvay launches high-performance carbon fiber tape for offshore oil and gas applications

Evolite F1050 is a market first high-performance thermoplastic composite with continuous carbon fiber reinforcement for demanding offshore oil and gas applications.

-

PEEK or PEKK in future TPC aerostructures?

Which is better for in-situ consolidated thermoplastic composite primary structures? Materials play a part as to whether a one-step or two-step process will prevail.

-

JEC World 2018: The highlights

JEC World is the composites industry’s largest trade show and did not disappoint this year.

-

JEC World 2018: Highlights

You will read more about what we discovered at JEC World 2018 in the coming weeks and months, but for now this is a quick review of some of the highlights from the world’s largest composites trade show.

-

Fast and Faster: Rapid-cure resins drive down cycle times

New systems include sub-1-minute cures ideal for higher automotive production volumes.

-

Consolidating thermoplastic composite aerostructures in place, Part 2

Thermoplastic composite structures could eliminate the autoclave and fasteners, but will a one- or two-step process prevail?

-

I want to say two words to you: “Thermoplastic tapes”

Thermoplastic tapes are not new to composites, but they soon will join the primary aerostructures material palette and could be their future.

-

Solvay, deBotech announced as USA Bobsled and Skeleton technology partners

Solvay and deBotech will provide custom designed high quality carbon fiber composite equipment.

-

Improving one-piece aerostructures by automating preforming

IAI’s fully automated “one-shot” RTM production line cuts helicopter seat cost 30% vs. hand layup prepreg.

-

Solvay, Strata joint venture to supply Boeing with composite materials

Facility to be commissioned in 2020 and to anchor a growing advanced manufacturing sector.

-

Solvay acquires European Carbon Fiber GmbH

The strategic acquisition of European Carbon Fiber enables Solvay to develop a portfolio of large-tow carbon fibers to complement its existing range of pitch and PAN aerospace grade carbon fibers.

-

Fiber-metal laminates in the spotlight

Interest in FMLs is growing again as aeroengineers search for lightweight solutions adaptable to new narrowbody commercial aircraft.

-

How ready are progressive damage analysis tools?

In the past 15 years, progressive damage analysis (PDA) for composites, implemented in finite element analysis software, has been under development.

-

Automated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

-

2017 Paris Air Show is good for composites

There is definitely a lot going on this week at the Paris Air Show at Le Bourget airfield. Much of it relates to composites. Here’s a brief rundown.

-

RTM-based redesign advances safety for one-of-a-kind wind tunnel

Glass fiber and honeycomb spacers between compressor blades get upgraded to a higher factor of safety with less weight using solid carbon fiber and RTM.

-

JEC World 2017: Show report, part 1

JEC World 2017 was, by almost any measure, the biggest and busiest JEC event yet, and exhibitors came with much to show the world of composites about innovation in materials, equipment and technology.

-

JEC World 2017 exhibit preview

JEC World will be held March 14-16 in Paris. CW previews some of the products and technologies that will be at the show.

-

Composites industry is growing up—but hurdles still remain

It’s the era of when, not if, for the use of composite materials.

-

OOA composites in next-generation launch systems

As United Launch Alliance ULA replaces Atlas and Delta with next-generation launch rockets under the Vulcan name, supplier Ruag Space has been selected to provide lower cost/improved quality out-of-autoclave fabrication of Vulcan’s composite primary structures. Ruag will manufacture 5.4m payload fairings and 400-series interstage adapters for ULA’s Atlas V rocket.

-

Small companies, long-term impact

In a time known for owner “exit strategies,” longevity in family-owned composites businesses is heartening.

-

Structural adhesives, Part II: Aerospace

Tried-and-true legacy epoxies are a must for aerospace composites, but usage is increasing with improved forms.

-

Nanocomp Technologies Inc., Merrimack, NH, US

Its millimeter-length macro CNTs are finally realizing their commercial composites potential, with spacecraft applications leading the way.

-

Composites manufacturing — where the excitement lives

A regular CW columnist and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI, Knoxville, TN, US), Dale Brosius points out that for today's engineering students, a Ph.D in manufacturing could open the door to an exciting, alternative career path.

-

Thermoplastic composite wings on the horizon?

OUTCOME, a project under the Clean Sky 2 program, aims to industrialize out-of-autoclave thermoplastic primary aerostructure.

-

JEC World: Aerospace highlights

Fokker Aerostructures BV (Hoogeveen, The Netherlands), a GKN Aerospace company, demonstrated at its stand a thermoplastic composite aircraft demonstrator spoiler, fully functional and consisting of only three parts: top skin, bottom skin and a single spar.

-

JEC World 2016, the full report

CompositesWorld's editors report on the technologies and products that caught our eye at JEC World 2016, in early March.

-

Supply and demand: Advanced fibers

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs

-

Filament winding, compression molding combine on BMW M4 GTS

Cytec Solvay is debuting today a novel all-carbon fiber composite hood that it helped develop for the BMW M4 GTS, in cooperation with fabricator C-CON GmbH and automotive metals specialist Läpple AG.

-

IACMI – One insider’s perspective

A CW columnist, a composites industry consultant and the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (Knoxville, TN, US), Dale Brosius asks, “What if we took a ‘big hat’ approach to reach faster, more cost-effective solutions?”

-

VBO prepreg on wing structure

GE Aviation scores first use of OOA wing trailing edge on large commercial aircraft.

-

Aircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

-

“Smart tooling” cuts time and risk for complex unitized composite structures production

One-piece bladder tooling helps to actualize NASA/Boeing’s revolutionary fluted core design for next-gen cryogenic fuel tank skirt.

-

Plant tour: Spirit AeroSystems: Prestwick, Scotland, UK

Global aerostructures giant Spirit AeroSystems ventures into out-of-autoclave (OAA) composites manufacturing via vacuum infusion.

-

NASA/Boeing composite launch vehicle fuel tank scores firsts

Subscale 5.5m-diameter cryogenic tank demonstrator with innovative fluted-core skirt is formed via robotic AFP and cured out of the autoclave.

-

Classic harps in carbon fiber

Lever and pedal models less cumbersome, still classy.

-

Terma Aerostructures: Grenaa, Denmark

This Danish manufacturer of precision composite aircraft parts and components has emerged as a significant player in fabrication of Lockheed Martin’s F-35 Lightning II.

-

Cytec gearing up for automotive expansion

With a new automotive-focused Application Centre set to open in December, Cytec Industrial Materials is emphasizing material and process flexibility to help OEMs integrate composites into forthcoming cars and trucks.

-

Mubea Carbo Tech: High-quality auto composites go high-volume

Known for its precision and technical acumen in CFRP motorsports structures, MCT draws from its steel auto parts parent to push high-performance and industrial production to new plateaus.

-

Automotive composites: Thermosets for the fast zone

Epoxies continue to be developed for faster cure to meet automotive production rates.

-

Some thoughts on the M&A "heat wave"

CompositesWorld's editor-in-chief Jeff Sloan takes some admittedly educated guesses at the significance of the six momentous acquisitions that were announced in the short space from mid-July through early August in the composites industry.

-

Composite air brakes: Stopping the world’s fastest car

CFRP sandwich structures a key element of deceleration in the Bloodhound SSC rocket-powered racer’s two-run attempt at resetting the land speed record.

-

Thermosets vs. thermoplastics: Is the battle over?

Dale Brosius, the chief commercialization officer for the Institute for Advanced Composites Manufacturing Innovation (IACMI) and a regular CW columnist, sees a shift in the industry from infighting between proponents of thermoset and thermoplastic composites to a healthier competitive atmosphere that serves to make composites overall more competitive with legacy materials.

-

Turning ideas into innovative composites

From helmets to harps to the new Formula Lites all-carbon race car, Crawford Composites pursues perfection in a wide array of carbon fiber parts.

-

Heated composites

LaminaHeat enables heated composite tools and new opportunities for composites via multifunctional structures.

-

Uncompromising composite hyperbaric oxygen chamber closes the gap

Flexible filament-wound composite reduce weight and cost, increase performance of first portable high-pressure oxygen-delivery system.

-

Why South Carolina? Why now?

CW guest columnist Tom Lemire (T.F. Lemire Consulting Inc., Irvine, CA, US), comments on the aerospace industry's current attraction to this particular spot on the US map and wonders if it's the beginning of a trend.

-

Building TRUST in bonded primary structures

A DARPA program aims for certification via Bayesian process control system for the factory floor, bounding uncertainty and predicting reliability in real-time.

-

Ascent Tooling Group ascends via innovation

The world’s largest metal and composite moldmaker has a new name and continues to make a name for itself in closer control of large-part dimensional tolerance.

-

Supply and demand: Advanced fibers (2015)

Demand for advanced fiber, virgin and reclaimed, is on an upswing after a dip during the recent recession. Fiber suppliers are gearing up to meet an expected increase in demand as manufacturers in a number of composites end-markets scale up or start up part development and production programs.

-

The matrix (2015)

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here's a guide to selection.

-

Benzoxazines for OOA tooling

Can infusible formulations of this newer resin system produce aerospace-capable tools?

-

Plant tour: ATK Aerospace Structures, Clearfield, Utah, U.S.

High-volume, high-precision fiber and tape placement for the aerospace industry are among many specialties for this composites manufacturing behemoth.

-

Dark knights: Sleek trimarans surveil the seas

Epoxy-infused patrol boats outperform less nimble and more costly conventional naval craft.

-

Aerospace and automotive: Convergence on the horizon?

Guest columnist and composites industry consultant Dale Brosius reviews his own history with composites to support his contention that the once very different worlds of aerospace and automobile manufacture are not, as far as composites are concerned, so different anymore.

-

FACC: Aerospace infusion pioneer

Although it’s “new” to aerospace, liquid resin infusion has been the focus of R&D at FACC (Ried im Innkreis) since 2001. “The issue,” said FACC’s aerostructures product development director Hermann Filsegger, “is in getting 100 percent wetout with no voids in a large part with this much complexity.” That’s not, by any means, an easy task.

-

Spread-tow technology takes off

New, ultralight-areal-weight prepreg tapes form the thin-ply laminates will enable Solar Impulse 2’s sun-powered flight around the world.

-

Combining curing processes for faster part production

Regloplas USA (St. Joseph, Mich.) says it has demonstrated a tool heating method that overcomes poor temperature uniformity in autoclave curing processes.

-

The democratization of carbon fiber

Composites industry consultant and regular HPC columnist Dale Brosius says the battle for carbon fiber’s industrial market will be won by suppliers with the lowest costs and greatest capacities.

-

Onboard protection: Tough battery enclosure

Unique composite laminate provides crash protection for electric vehicle’s battery, occupants and first responders.

-

CAMX offers unprecedented new product access

CAMX 2014, Oct. 13-16 in Orlando, Fla., promises to be North America's largest ever composites trade show and conference. As a result, exhibitors are coming to the event with a wide array of new and existing materials, machinery, software and technology designed to help make composites fabrication faster, easier and more adaptable. CompositesWorld has been gathering information from CAMX exhibitors about what they will be featuring and introducing in their booths. This week's CAMX newsletter offers a preview of some of what you will find on the show floor.

-

Farnborough 2014 Airshow Report

No longer a novelty at aerospace trade events, composites nevertheless faced competition from conventional materials at this year’s event.

-

What will be the next major iteration in carbon fiber?

A consultant and the president of Dayton, Ohio-based Quickstep Composites, the U.S. subsidiary of Australia-based Quickstep Technologies (Bankstown Airport, New South Wales), Dale Brosius surveys the carbon fiber horizon for signs of what carbon fiber types will be pre-eminent.

-

2014 JEC Europe Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

JEC Europe 2014 Review

The composites world met again in Paris, vibrant, stronger, and more forward-looking than ever before.

-

VX Aerospace: Small company, big performance

Innovative design, OOA manufacturing and C-PLY laminate construction produce “big fabricator” aerostructures in fewer steps at low cost.

-

The Learjet 85: Large step out of the autoclave

HPC editor-in-chief Jeff Sloan examines the significance of the Bombardier Learjet 85’s first flight.

-

Styrene & cobalt: Headed for the exit?

Fair or not, styrene and cobalt are now considered harmful to humans. Here's an update on the impact this issue poses for the composites industry and what resin and additive manufacturers are doing about it.

-

Business and busy-ness

CT editor-in-chief Jeff Sloan returns for JEC Europe 2014 in Paris with observations about several intriguing composites industry trends.

-

Highlights: JEC Europe 2014

Composites enable high performance and lower weight in washtubs, wheelchairs and engine exhaust cones. Plus new, ultralight materials.

-

BMI and benzoxazine battle for future OOA aerocomposites

Offering weight, cost and process advantages, these “hot zone” resins are moving down the thermometer and into out-of-autoclave structural applications and autoclavable tooling now dominated by epoxies.

-

Resin-infused MS-21 wings and wingbox

Moscow-based aeromanufacturer uses out-of-autoclave composites in attempt to leapfrog Airbus and Boeing with wider, lighter, more efficient single-aisle airliner.

-

Inside a thermoplastic composites hotbed

As production of the A350 XWB ramps up, so does manufacture of the thermoplastic fuselage clips the plane requires. HPC sees how it’s done.

-

A350 & A400M wing spars: A study in contrasts

In three short years, GKN Aerospace has taken its wing spar manufacturing strategies to new heights by dramatically reducing part weight, process complexity and production-cycle duration.

-

HPC's 20th Anniversary: Thanks to HPC’s charter advertisers

Every trade publication lives and dies by its advertisers, and those who had the gumption to ante up for HPC’s premier issue are listed here and those who are still with us (see page numbers below) are gratefully recognized with the HPC 20th Anniversary Medallion.

-

HPC turns 20

Celebrating two-decades of composites advocacy.

-

Carbon fiber composites: Into the automotive mainstream?

Altair Engineering Inc.'s (Troy, Mich.) VP of aerospace solutions Robert Yancey asks if automakers will follow aeromanufacturers in embracing carbon fiber.

-

Lightning strike protection strategies for composite aircraft

Tried-and-true materials thrive, but new approaches and new forms designed to process faster are entering the marketplace.

-

SAMPE Europe 2013/JEC Europe 2013 highlights

Held concurrently, these two seminal European composites events weathered a rare Parisian snowstorm to plumb the depth and breadth of the industry.

-

Building a better tail boom

Out-of-autoclave carbon fiber/thermoplastic demonstrator is a 30 percent lighter drop-in replacement for an existing aluminum design.

-

U.S. crew and cargo candidate takes shape with composites

Crew-capable Dream Chaser to enable ISS transport missions from U.S.

-

Mergers and acquisitions activity in the composites industry: A review of 2012 and the outlook for 2013

M&A adviser Michael Del Pero charts the likely course of M&A activities in the composites industry during 2013.

-

Cutting and laser layup technology supports tier fabricator in Boeing project

Prototype production for The Boeing Co.’s (Chicago. Ill.) Enhanced Medium Altitude Reconnaissance and Surveillance System (EMARSS) aircraft gets a boost from cutting and templating hardware/software supplied by Gerber Technology (Tolland, Conn.)

-

EAA AirVenture 2012 Airshow Report

New composite light sport aircraft attract flyers at the Oshkosh Fly-in, especially those with a flair for the amphibious.

-

Composite fuselage helps HondaJet upend biz-jet market

CFRP composites enable unitized structure with low-drag aerodynamics that transform aircraft performance and reduce cost.

-

An out-of-autoclave progress report

CW Conferences director Scott Stephenson recalls Dale Brosius’ update on Quickstep’s out-of-autoclave work for the F-35 program.

-

2011 International Paris Air Show

At the 49th event, records are set for attendance and aircraft orders, and airframers go on record about composites-related developments.

-

JEC Paris 2011 Review

This annual Paris trade event’s statistics signal an advanced composites resurgence.

-

Carbon fiber/PEEK takes hydraulic pump to new depths

A switch from metal to composites reduces weight, minimizes part deflection in ultradeep ocean installations.

-

Reinforced thermoplastics in aircraft primary structure

Carbon/PEKK floor beams prove production worthiness of lower cost, fast coconsolidation process.

-

Microwave: An alternative to the autoclave?

Aerospace composites manufacturer GKN evaluates microwave oven practicality and cost-effectiveness.

-

JEC Paris 2011 highlights

The news from this annual Parisian in-gathering of composites professionals is heavily weighted toward automotive lightweighting.

-

M&A activity in the composites industry

Michael Del Pero (FocalPoint Partners LLC, Los Angeles, Calif.) comments on the uptick in mergers and acquisitions activity in the recovering advanced composites segment.

-

Carbon fiber market: Cautious optimism

As the recession recedes, the demand for carbon fiber, and the supply to meet it, will exceed prerecession expectations.

-

Out-of-autoclave prepregs: Hype or revolution?

Oven-cured, vacuum-bagged prepregs show promise in production primary structures.

-

GKN A350 spar program update

Automated fiber placement to replace established tape laying/drape forming process for the composite rear spars on the new midsize commercial passenger jet.

-

Learjet 85 composite pressurized cabin a cost cutter

Single-piece carbon fiber composite structure selected over multipiece aluminum fuselage barrel section in new bizjet design.

-

SQRTM enables net-shape parts

New out-of-autoclave process combines resin transfer molding with prepregs for complex helicopter part prototype.

-

The Private Space Race

NASA passes the development torch to legacy contractors and NewSpace entrepreneurs, igniting a new competition in space transport.

-

F1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

-

EAA AirVenture 2010

Rain on the Wittman Field runways can’t dampen Oshkosh Fly-In enthusiasm.

-

Thermoformable thermoplastic composites

Thermoplastic composites that can be shaped into finished parts via thermoforming are proliferating as the thermoforming process gains traction, particularly in aerospace manufacturing. The following short article and chart provide some guidance in terms of sourcing.

-

Shared composite material property databases

Work at NCAMP is proceeding, with several new materials undergoing testing.

-

SAMPE 2010 Seattle Showcase

SAMPE’s first-ever foray into Boeing Country wrapped up with the M&P organization’s biggest draw this decade.

-

Aerospace-grade compression molding

Continuous Compression Molding process produces structures 30 percent lighter than aluminum at costs that have both Airbus and Boeing sold.

-

2010 SAMPE Europe/JEC Paris Showcase

Record crowds and reignited technological development testified to the composite industry’s renewed health and the recent recession’s demise.

-

JEC Composites Show 2010 Highlights

Despite the volcanic ash that clouded air travel, an eruption of new technology and new business did much to dispel the clouds of economic recession.

-

Very Light Jets Creating A Demand For Composites

"Baby" jets are causing an aviation buzz but will the market exist?

-

Fuselage skins redesign streamlines production

Cirrus Aircraft’s SR22 second-generation design improves functionality and enables faster processing.

-

Advanced Composite Cargo Aircraft proves large structure practicality

Dr. John Russell reports that the successful completion of a flying aircraft in the the Advanced Composite Cargo Aircraft program has demonstrated the holistic impact that composites technology can have on future aircraft development.

-

Antiballistics: Composites in the cross hairs

An increasing quantity and variety of fiber/polymer solutions are stopping bullets and blast debris in armored ground vehicles and stationary structures.

-

Skinning the F-35 fighter

Fastening the all-composites skin on the Lightning II requires machining and drilling technology that is optimized for cost-efficiency.

-

Resins for the Hot Zone, Part II: BMIs, CEs, benzoxazines and phthalonitriles

Next-generation aerospace programs demand higher temperatures for structural and hot-section components, fostering advances in thermoset resin chemistry.

-

Modular composites: A perfect fit in new medevac helicopter

Bell Helicopter's new manufacturing parardigm replaces sheet metal with composites in a modular "snap fit" design.

-

Corvette's carbon hood creates shock and awe

North America’s first mass-produced, all-CFRP hood raises the bar for production sports cars.

-

Resins for the Hot Zone, Part I: Polyimides

As next-generation aerospace programs demand higher service temperatures in structural and hot section components, a variety of polyimides vie for program approval.

-

JEC Composites 2009 showcase

Despite the doleful state of the global economy, the turnout in Paris — exhibitors and visitors — proved surprisingly strong.

-

SAMPE Europe/JEC highlights

The global economy might be on the wane, but there was little evidence of it at the annual SAMPE Europe conference and nearby JEC Composites Show in Paris.

-

Lightweight, stable large-tool concept requires no master model

After two years of testing, partners Advanced Composites Group (ACG, Tulsa, Okla.) and GrafTech (Parma, Ohio) are commercializing the ACG GRAFOAM FPA-20 tooling system, a new concept in dimensionally stable, low-mass, high-temperature-compatible composite tooling. The system’s foundation is carbon foam.

-

Thermoplastic composites: Inside story

Reinforced thermoplastics buy their way into structural aircraft interior components.

-

Aircraft simulation gets composites aware

Rapid software evolution enables faster, better virtual solutions to complex composite design problems.

-

Unmanned rotorcraft passes stringent German Navy shipboard tests

CAMCOPTER’s high strength-to-weight ratio is made possible by composite materials.

-

Shared composite material property databases

For more than a decade, NASA, FAA, industry and academia have been working toward the goal of creating a centralized composite material property database similar to that for metals. Their efforts, while productive, have not come with the war-like strength that the standardization of metals did. The composites industry is guided by Composite Materials Handbook 17 or CMH-17 (formerly known as MIL-HDBK-17).

-

JEC COMPOSITES 2008 show review

Composites professionals converged on this annual Parisian gathering in greater numbers than ever before, confident that the market’s global growth will continue.

-

Flying high on composite wings

FRP wings, fuselages and other primary and secondary structures on GA prop, turboprop and jet aircraft help lift this market to unprecedented heights.

-

Out-of-autoclave tooling gets out of the blocks

General aviation aircraft manufacturer adopts new oven-cure tooling.

-

Aligned discontinuous fibers come of age

Discontinuous but aligned carbon fibers are proving formable and formidable in high-performance, compound-curvature applications.

-

Engineering Insights: Composites Lessen Load in Fuel-Cell Demonstrator

CFRP decklid helps offset fuel-cell system weight to meet vehicle weight target.

-

Carbon/BMI and carbon foam form Invar alternative

For years, Invar steel has been the material of choice for tooling that must endure repeated autoclave cycling in volume part production. Invar's disadvantage is its relatively high density and resulting large mass. As processors move away from hand layup and toward automated fiber and tape placement, there is a

-

Tooling Update: New dimensions in tooling

Nanoenhancements, out-of-autoclave strategies and low-pressure RTM headline efforts to increase mold quality and productivity and cut tool cost.

-

Friction products: Carbon fiber stopping power

Low weight, thermal shock resistance, and extreme strength drive growth of carbon-reinforced friction products and materials in brake applications.

-

JEC COMPOSITES 2007 Product Showcase - 7/1/2007

The annual Paris conclave showcases the global expansion of composites.

-

JEC Composites 2007 Product Showcase

This year’s Parisian exhibition provides key evidence of the composites industry’s unprecedented breadth and technical sophistication.

-

Tidal Turbines to Mine Marine Megawatts

Composites help subsea turbines harvest electrical energy from ocean currents.

-

Bonding Technology: Thermosetting Structural Adhesives

A wealth of epoxies, polyurethanes and acrylics speed assembly and cut manufacturing cost in an ever-wider range of composites applications.

-

JEC COMPOSITES 2007 Highlights

Advanced composites make notable marks not only in traditional aerospace apps, but in automotive, sport and infrastructure arenas as well.

-

Boeing 787 Update

Approaching rollout and first flight, the 787 relies on innovations in composite materials and processes to hit its targets

-

Market Trends: The Composites Affordability Initiative, Part I

The Air Force Research Laboratory's Dr. John Russell outlines the U.S. Department of Defense Composites Affordability Initiative. Part I of a two-part series.

-

Lightning Strike Protection For Composite Structures

Composite structures are more vulnerable to damage than metal, but today's LSP products offer proven protection.

-

Composite spoilers brake Airbus for landing

New RTM'd carbon composite center hinge fitting withstands 20-ton air load in commercial jet spoiler assembly.

-

Autoclave Quality Outside The Autoclave?

Pioneers of out-of-autoclave processing in aerospace applications answer a qualified but enthusiastic Yes!

-

Thermoplastic composites gain leading edge on the A380

Breakthrough manufacturing process produces lightweight, affordable glass-reinforced PPS J-nose on the worlds largest commercial aircraft wing.

-

Carbon fiber race car technology hits the streets

Porsche equips its new Carrera GT with the first-ever all-carbon chassis on a production automobile.

-

Designing for dimensional stability in space

The accuracy of orbiting instruments depends on skillfully designed and manufactured composite components.

-

Distributors and their role

These key players in the supply chain provide indispensable services not just in the commodity markets but in advanced material arenas as well.

-

Are high-temp thermosets ready to go commercial?

Developed for the U.S. military, these high-performance matrices are branching out into wider use.

-

GENOA modeling software closely predicts composite structuralfailure

Progressive failure analysis and material-level damage modeling enable life prediction of composite structures.

-

Nacelle manufacturers optimize hand layup and consider closed molding methods

Focused on optimizing traditional hand layup, nacelle and thrust reverser manufacturers cast an eye on future use of automation and closed molding.

-

Newer surfacing films reduce surface on demolded composite parts

A wide variety of products reduces finishing costs in many applications.

-

Airline maintenance facility cuts repair costs while improving part quality

Delta TechOps uses simulation software to standardize repair procedures and bring work back in-house.

-

Composites combat ready in UCAVs

As unmanned aircraft are designed from inception for combat duty, composites will carry the payloads in structural components.

-

Composite rib structure for Airbus A380 vertical tail

Fabricator exceeds Airbus performance requirements with hand layed rib truss structure for A380.

-

Advances in sizings and surface treatments for carbon fibers

As carbon reinforcements find new applications, unfamiliar processes and resin systems make sizing and treatment surprisingly hot topics.

-

New film and paste adhesives for specialized applications

Customer performance demands drive thriving film and paste technology development.

-

Fiber Placement The Centerpiece Of NCAM

Cryogenic composites just one facet of Lockheed Martins National Center for Advanced Manufacturing.

-

Cocured materials damp vibration in composite structures

Viscoelastic layers convert strain energy into heat, suppressing the harmful effects.

-

Liquid Composite Molding Achieves Aerospace Quality

Improvements in materials, tooling and process control bring RTM and VARTM into the realm of aerospace components.

-

Airbus A340 carbon composite spoiler made with RTM

When FACC AG (Ried, Austria) contracted to fabricate a demonstration composite replacement part for a highly stressed aluminum spoiler center fitting on the Airbus A340-600, the company wanted to use resin transfer molding (RTM) because the part's complex shape would be difficult to produce consistently and

-

Carbon Composites for Sports Cars and Mass Market Cars

A confluence of market demand, new product development and competition among automakers fuels growth in use of carbon fiber composites.

-

SAMPE Wrap Up And Product Showcase

Exhibitions on both sides of the Atlantic spur optimism and spotlight innovative technology.

-

An Elegant Solution For A Big Composite Part

The rear pressure bulkhead for the Airbus A380 employs resin film infusion.

-

Complex Composites Lighten Nato Copter

Dutch consortium develops advanced composite critical landing gear that meets NH90 helicopter performance requirements.