Three new 3D printing technologies for composites

Fiber-reinforced composite tooling, ceramic matrix composites (CMCs) and woven fiber composites are all now the realm of 3D printing.

|

Cosine Additive’s large format AM1 printer has been developed to deliver high-quality carbon-reinforced thermoplastic parts like this 10% CF/polycarbonate thermoforming mold (left) and intake manifold (far right). SOURCE: Cosine Additive

3D Printed Fiber-reinforced Tooling

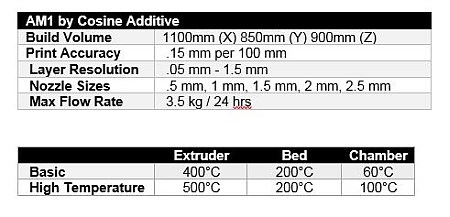

Cosine Additive (Houston, TX, US) claims the premise behind its development of the large-format (1.1m x .85m x .9m) AM1 printer is simple: increase the usefulness of industrial, large format, additive manufacturing by exponentially decreasing the cost barrier. “We come from a CNC manufacturing background,” says co-founder and CTO Andrew McCalip, “so we know there is a crossover point where it becomes uneconomical to machine tools and fixtures out of billet materials.”

McCalip is a structural engineer with a background in automotive applications using carbon fiber. “We were using rapid prototyping to make tooling and molds as well as first article pieces,” he recalls, “and we saw a need for better technology.”

The AM1 has been developed to deliver high-quality carbon fiber-reinforced thermoplastic parts for use as thermoforming and layup tools, high strength cores and jigs. It can print with a variety of high temperature materials for parts that can be used in autoclave processing. With his engineering and applications background, McCalip thought it was important to decouple the hardware, software and materials in order to give users the ability to innovate and adapt the technology as necessary to meet their particular needs. Thus, the machine is modular with upgradeable hardware and uses commercially available materials. AM1 pricing runs from $85,000 to $175,000, depending on the options selected.

The other difference is in speed and fiber length. “Where a Fortus machine deposits a kilogram of material in 24 hours, we can lay 9-11 kilograms to realize larger parts,” says McCalip. However, the company is partnering with Oak Ridge National Laboratory (ORNL, Knoxville, TN, US) to push this even higher, with a goal of over 4.5 kg/hr. One of the first goals is to use the AM1 to produce a part measuring more than .8m x .8m x .8m and weighing 23 kg in less than eight hours.

“Our hope is that this partnership, and the ensuing products, will help to excel new applications for additive manufacturing,” said Lonnie Love, ORNL group leader of manufacturing systems research. Cosine Additive has already partnered with another company called Essentium Materials to develop the EM1 3D printer, which uses electric fields to 3D print parts with stronger Z-axis properties.

“We also use resin-based pellets vs. filament,” McCalip explains, “with carbon fiber loadings up to 35%.” However, Cosine Additive is pursuing longer fiber compounds. “We’re developing a non-screw based pellet extruder to avoid shearing the fibers and preserve fiber length,” says McCalip, noting a goal of 5-10 mm in the as-printed part. The new extruder will fit on the existing head of the AM1 printer. “This is our top priority outside of increase deposition rate.” Why long fiber? “For the majority of the tooling applications that the market has brought to us, long discontinuous fiber is a better fit,” McCalip answers. “These are not flying parts, so the mechanical properties of discontinuous fibers are not an issue and they also enable more complex geometries.” He asserts that pursuing continuous fibers really just leads back to automated tape laying and fiber placement, countering: “We can produce first article composite parts much quicker than ATL or AFP.”

McCalip sees potential for Cosine Additive to use recycled carbon fiber compounds as well. “We’d rather not use expensive grades of fiber,” he says, “we’re aiming for $2/lb for the thermoplastics, so using cost-effective fibers with the appropriate properties makes sense.”

Of course, the AM1 is also being used to build plenty of fiber-reinforced parts other than molds, such as a carbon fiber/polycarbonate composite intake manifold. For more details, see their online parts gallery.

3D Printed CMCs

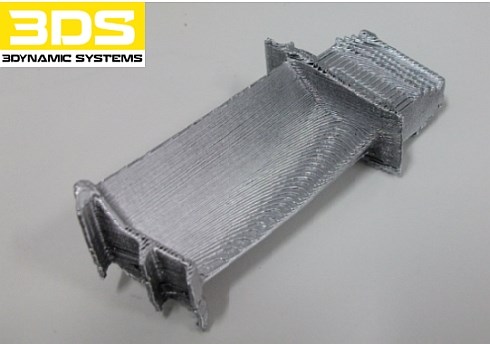

3Dynamic Systems Ltd. (Swansea, Wales, UK) produces advanced 3D Printer materials for a range of high-end applications. Based upon two years of research and development, the company has harnessed a new type of ceramic matrix composites (CMC) technology using a revolutionary new 3D Printing platform which is being targeted for aerospace applications.

The 3Dynamic Systems print system is adapted from fused deposition modeling (FDM), but operates at a higher temperature than conventional FDM, with materials extruded at 315°C. The printing filament is made from suspending fine ceramic micro fibers in a special thermoplastic polymer that is stable up to 325°C. This is then printed to form a 3D aerospace component structure. The filament can be printed with extruder temperatures ranging from 285°C to above 315°C, but testing has revealed that different temperatures affect the accuracy of the final print.

3D Printed CMC turbine blade after processing in a 1450°C furnace.

SOURCE: 3Dynamic Systems.

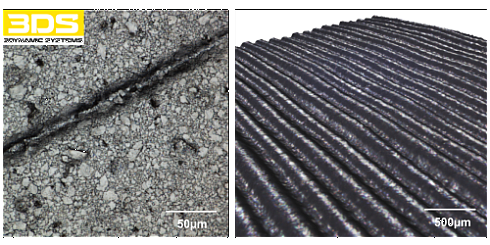

The ductile 3D printed structure is then heat treated in a furnace to 1450°C, transforming it into a CMC component. This pyrolysis is indeed a key process. “It has to be carried out with the absence of oxygen and a vacuum in order to eliminate porosity,” says lead scientist Dr. Daniel J. Thomas. Though a turbine blade structure can be printed in roughly 5 hours, the heat treatment requires another 24 hours. “The annealing and complex heating cycles required are crucial for making our form of CMC,” notes Thomas. “If the material is placed straight into a high temperature furnace then it cracks. Care has to be taken in order to achieve the appropriate heat treatment.”

Micrograph of the post fired CMC turbine blade microstructure and the formation of the layers during the 3D Printing process. SOURCE: 3Dynamic Systems.

Thomas says this new technology shows excellent potential. “This 3D printing process allows for exotic new shapes to be formed with complex hollow internal cooling sections, making a single seamless component.” He adds that the aerospace industry’s demand for components that can handle higher temperatures is driving this type of technology forward and creating a new market for advanced 3D printed components.

“We started to work on this material as a means to build a new type of bone implant,” says Thomas, “however, due to an inadvertent mistake in the fabrication process, we found that we had produced a material which has desirable structural and thermal properties”.

3Dynamic Systems has developed technology to print CMCs aimed at high-temperature aerospace applications. SOURCE: 3Dynamic Systems.

The current build envelope of the new system is 300mm (X) x 200mm (Y) x 400mm (Z) with a layer resolution of 0.075 - 0.100 mm. There are no constraints on geometries. Indeed, even hollow sections and overhangs are possible. Thomas explains, “Using a special dual extrusion system that we have recently built, we can produce a sacrificial scaffold made of high impact polystyrene (HIPS). The scaffold is then dissolved in water and the component is subsequently heat treated.”

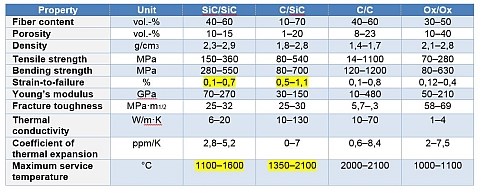

Though 3Dynamic Systems is still evaluating how these CMCs stack up to traditional carbon and silicon carbide composites (e.g., C/C, C/SiC, SiC/SiC, Ox/Ox, etc.), testing to date shows elongation to rupture is 1.1% and temperature resistance up to 1350°C. So this falls roughly between SiC/SiC and C/SiC in the table below.

From “Aeroengine Composites, Part 1: The CMC invasion”, CW Aug 2015.

3Dynamic Systems’ reach into composites does not stop here. The company is also working on the 3Dynamic Spider, a technology developed for the space industry to make carbon fiber structures for low-cost, lightweight yet strong and durable components. “The technology is taking shape quite nicely,” says Thomas. “We have developed our machines and manufacturing capability and will be up to full-scale production by the end of this year.” New materials using thin-diameter, discontinuous carbon fibers are being made that can be supplied to customers for use with any conventional 3D printer.

3Dynamic Structures is also working to commercialize 3D printing of integrated electronics, biosensors and construction materials.

Selective Lamination Composite Object Manufacturing

EnvisionTEC (Dearborn, MI, US and Gladbeck, Germany) has already commercialized a range of 3D printing machines, including the 3D-Bioplotter for applications in Computer Aided Tissue Engineering and several machines that can cure and/or post-cure with ultraviolet (UV) light using the company’s Scan, Spin and Selectively Photocure (3SP) technology. It has also become the exclusive supplier of Viridis3D’s (Lowell, MA, US) technology for 3D printing sand molds and cores.

|

SOURCE: www.3dprintingbusiness.directory and envisiontec.com.

Now EnvisionTEC has developed the SLCOM 1, which can print objects up to 610 mm by 762 mm with a 610 mm height using a new patent pending process called Selective Lamination Composite Object Manufacturing (SLCOM). Aimed at industrial scale production of 3D printed parts from woven composite materials, SLCOM technology builds composite parts layer-by-layer using laminated thermoplastic composite fabric sheets from a roll.

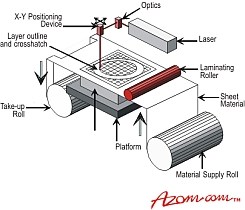

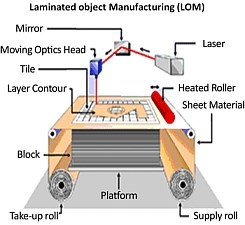

As can be seen below, Laminated Object Manufacturing (LOM), developed by Helisys Inc., now Cubic Technologies (Torrance, CA, US) over a decade ago, is not new. The innovation with SLCOM is replacing the traditional paper materials with composite prepreg or semipreg roll goods.

SLCOM is based on Laminated Object Manufacturing (LOM), which bonds and cuts sheet material using a computer guided laser and heated roller.

SOURCE: Azom.com and Helisys via www.metal-am.com.

The SLCOM 1 can process a wide range of custom made thermoplastic reinforced unidirectional or multidirectional woven fibers tailored to performance needs. Reinforcements currently include glass, carbon or aramid fibers and Nylon 6, Nylon 11, Nylon 12, polyetheretherketone (PEEK), Polyetherketoneketone (PEKK), Polycarbonate (PC), and many others.

The technology targets high-quality 3D-printed parts for use in aerospace, automotive, consumer products, sporting goods, and medical applications. The composites can reportedly be tailored for exceptional toughness, environmental resistance, vibration dampening, low flammability, high wear resistance and a high strength to weight ratio.

In an interview on 3dprintingindustry.com, EnvisionTEC CEO Al Siblani explained that SLCOM1’s origin came from looking at the preponderance of metal 3D printing:

“We wanted to do something that has not been done before, so we looked primarily at composites, and we looked primarily at composites that are not unidirectional, but more which is bidirectional or multidirectional. We decided now that the carbon fiber pricing has gone down and the fiberglass fabric pricing has gone down that it was viable to develop a technology in 3D printing that would allow us to deliver parts that would have infinite shelf life, have very high strength and stiffness, and be very lightweight, so we’re looking for a material that is really a breakthrough that will take 3D printing into the next phase where automotive and aerospace can benefit drastically from it.”

Siblani notes that the SLCOM1 can use existing materials, noting possible improvements in aircraft brackets. He also suggested the technology could offer an alternative to hand layup parts and may even use thermosets in the future.

The specifics of SLCOM processing are also detailed. Preheated thermoplastic matrix roll goods are fed onto the print bed and cleanly cut with an ultrasonic cutter. A mechanism similar to an inkjet head applies a wax-like substance in “crosshatch” areas where no lamination is desired. A heated pressure roller melts the thermoplastic matrix to ensure full impregnation and applies pressure to consolidate the plies. The feed roll is then advanced so that the waste from cutting is wound onto the take-up roll and new material is positioned on the bed. Cutting, wax application to crosshatch areas and consolidation are repeated until the part’s laminate stack is completed. After that, the part is “de-cubed” — meaning all of the crosshatch areas are easily removed because they are not stuck together — a process which is claimed to take minutes, not hours. SIblani says the resulting parts are not near-shaped products but instead finished goods, with properties equivalent to or better than those from hand layup.

Siblani says this method does not need to register sheets on top of each other yet still produces very accurate parts. He also says the whole build area sits on a table which can rotate in a clockwise or counterclockwise direction, applying the next layer in a different direction very efficiently to build a customized layup sequence. The SLCOM1 is described as “high speed” for industrial production and Siblani thanks SME’s RAPID show (May 16-19, 2016, Orlando, FL, US) for allowing “all the big names” in aerospace to take a first look at the machine before the opening of the exhibition.

Other industry articles have suggested the SLCOM 1 will cost around $1 million and will begin shipping at the end of 2016/beginning of 2017.

Related Content

Optimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

Read MoreActive core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreAutomated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreComposite sidewall cover expands options for fire-safe rail components

R&D project by CG Rail explores use of carbon fiber-reinforced thermoplastics and recycled manufacturing scrap to meet fire safety, weight and volume targets.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More