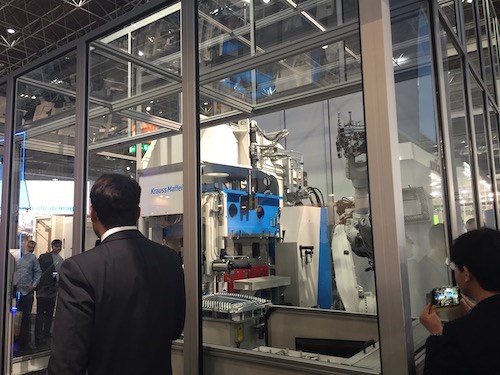

Video: KraussMaffei T-RTM demo at K 2016

Live demos are found almost everywhere you look during the K show. One of particular interest was KraussMaffei’s Thermoplastic Resin Transfer Molding (T-RTM) demo.

Demos are the stars of the show at K and one that stood out was KraussMaffei’s Thermoplastic Resin Transfer Molding (T-RTM) process, which demonstrated the production of an automotive fiber composite structural component with metal inlays under series production conditions. Frames for the roof shell of the Roding Roadster R1 sports car were created several times a day at the trade show booth. This roof frame features a hybrid construction of fibers in conjunction with plastic and metal. This makes it possible to process both glass and carbon fibers with reliability, according to the company.

Besides KraussMaffei, the following development partners were also involved in producing the Roding Roadster R1 technology demonstrator: Forward Engineering (component design, hybrid concept), Alpex Technologies GmbH (T-RTM mold), Dieffenbacher (production of preforms/handling), Saertex (fiber layers), Henkel (bonding), Handtmann (aluminum inlays), TUM / LCC (fiber selection) and Keller (extraction technology).

Check out this video of the demo where you’ll hear employees explain both the process and materials involved:

Related Content

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

-

Composite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

-

VIDEO: One-Piece, OOA Infusion for Aerospace Composites

Tier-1 aerostructures manufacturer Spirit AeroSystems developed an out-of-autoclave (OOA), one-shot resin infusion process to reduce weight, labor and fasteners for a multi-spar aircraft torque box.