Artemis Technologies and Creative Composites partner on eFoiler to cut drag on fast vessels by 90%

Composites-intensive electric propulsion system will make marine travel at high-speed and long-range commercially viable and help meet U.K.’s 2025 zero-emissions requirements.

WatchProving out LM PAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test Toray LM PAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

WatchUsing mobile susceptors to innovate thermoplastic induction welding

IS Groupe and Arkema patent ISW for high-strength UD welds, temperature control and 50% less energy.

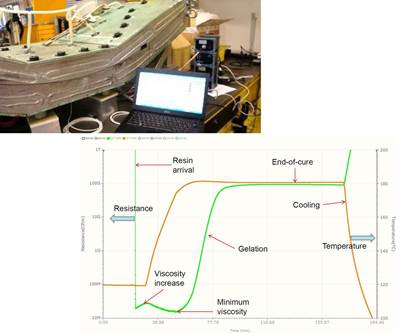

Read MoreDC dielectric sensors for industrial composites production

Synthesites in situ process monitoring enables cure decisions based on real-time Tg evaluation that can reduce cure cycles by up to 50%.

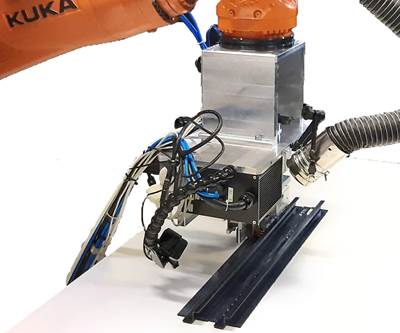

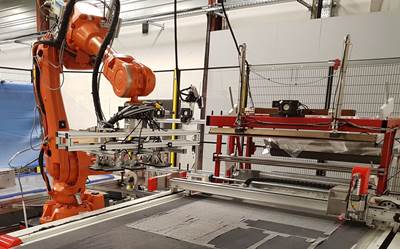

Read MoreIRT Jules Verne, Airbus and Fives launch MADRAS automated textile deposition line for WING project

Goal is full-scale testing of large, complex shape preforms at 5-6 times faster speeds for future aircraft.

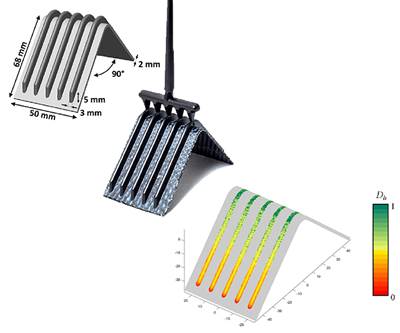

WatchNew research provides guidance for optimized thermoplastic composite overmolding

TPRC process modeling and testing of single- and dual-step processed parts points to optimum process conditions and improved design features.

Read MoreFAURECIA to supply hydrogen storage systems for 1,600 Hyundai heavy-duty trucks

Delivery of 10,000 composite tanks proves industrialization strategy of 20% lower weight, 50% lower cost components

WatchSolvay showcases low-cost prepreg and parts approach using Cygnet Texkimp filament winder

High-speed, tailored preforms are used with Solvay double diaphragm forming (DDF) and compression molding to produce cost-effective, medium-volume auto and aero parts.

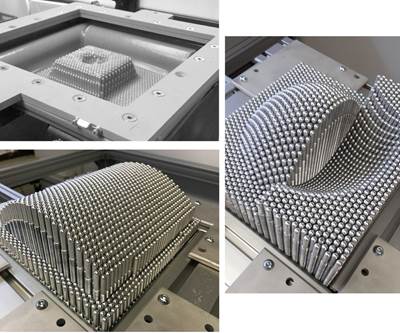

WatchDYNAPIXEL: automated, reconfigurable molds

CAD-driven system cuts time for design iterations, enables cost-effective customized jigs and molded parts.

Read MoreRolls-Royce starts manufacture of world's largest fan blades, made with composites, for UltraFan demonstrator

CFRP blades and fan case cut weight for twin-engine aircraft by 700 kilograms

WatchSTELIA Aerospace participates in AILE project with Bombardier

STELIA Aéronautique Canada’s R&T teams will lead the project to build a thermoplastic composite trailing edge flap as a testbed for Bombardier.

WatchCompression RTM for production of future aerostructures

Automated preforming and 5-min resin infiltration show a way forward for lower-cost CFRP primary structures.

Read More