ZAero project update

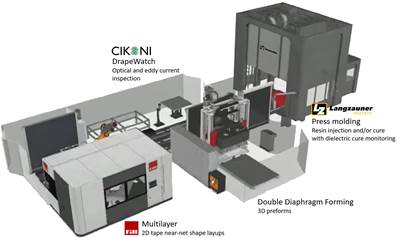

The 2019 final review demonstrated integration of an automated CFRP process chain: AFP inline inspection and rework, cure and resin flow sensors, part performance prediction and a decision support tool for line operators.

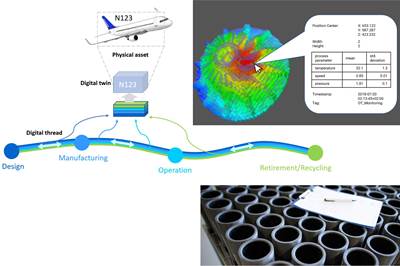

Read MoreDigital thread vs. digital twin

Visualizing the difference between digital representations and data flows and understanding the applications that are changing composites manufacturing and business models.

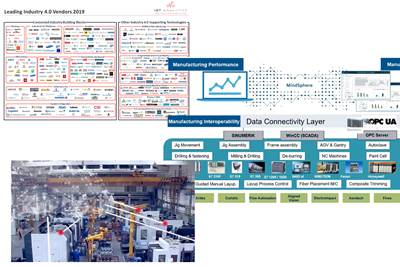

Read MoreComposites 4.0: Where to start?

Sensors, IoT platforms, data analytics — the tools for more intelligent, efficient manufacturing abound, but where to start is actually much simpler.

Read MoreNo business case for reteaching robots

DLR Center for Lightweight Production Technology has developed an AI-equipped work cell where collaborative robots can switch from producing composite rear pressure bulkheads to fuselage panels without requiring reprogramming or retraining.

WatchComposites 4.0: Architecture and ontology

Adaptive systems, IoT platforms and apps, the need for 4.0 standardization and a new way to develop and certify composite aerostructures.

Read MoreRemotely installing an AFP system amid COVID-19 travel restrictions

Addcomposites has completed remote installation of AFP-XS for Regional Institute of Advanced Materials (IRMA) in France.

WatchSwinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

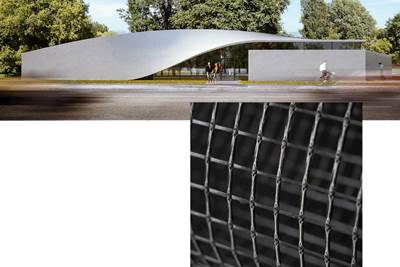

WatchCarbon fiber-reinforced concrete accelerates in Germany

TU Dresden and C3 – Carbon Concrete Composite demonstrator aims to reduce concrete material use by 50% and CO2 emissions by up to 70%; Hitexbau touts high-volume automated production for carbon fiber textile grids.

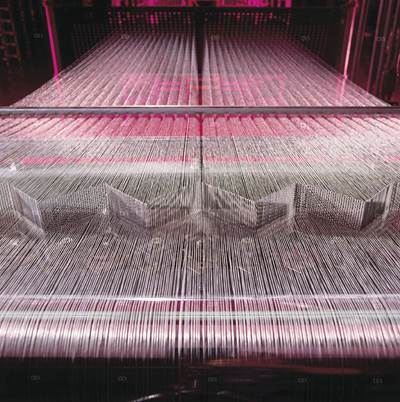

WatchThe making of glass fiber

The old art behind this industry’s first fiber reinforcement is explained,with insights into new fiber science and future developments.

Read MoreCoriolis Composites and Edixia develop inline inspection for AFP

Video and discussion of how the sensor and software operate to boost composites productivity

WatchInnovative pressurized hydrogen storage for integrated vehicle structures using composites

Chained tubular storage tanks using semi-finished thermoplastic composite products offer flat designs aimed at easy integration into universal vehicle architectures.

WatchVertical Aerospace used Plyable to go from CAD to first flight in less than 90 days

Composite tooling specialist’s online portal, distributed manufacturing network and automated tool design helped optimize CFRP molding tools and timeline.

Read More