New research provides guidance for optimized thermoplastic composite overmolding

TPRC process modeling and testing of single- and dual-step processed parts points to optimum process conditions and improved design features.

Share

Read Next

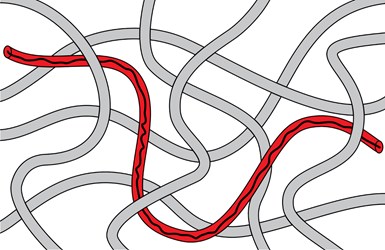

Overmolding is a technology in which a thermoplastic composite laminate is thermoformed and subsequently injection overmolded. This near-net-shape manufacturing process is well suited for automated large series production of complex 3D structures with excellent structural performance and a high level of function integration.

However, the industry lacks process design tools. Responding to this need, researchers at the ThermoPlastic composite Research Center (TPRC, Enschede, Netherlands) analyzed the overmolding process, focusing on the bond strength between the overmolded composite laminate and the injected polymer resin/reinforced composites. Using process modeling and mechanical testing, they evaluated both a single-step and a dual-step process. Results showed distinctly different process mechanisms and resulting material structure and mechanical performance in the overmolded composite parts.

Starting from De Gennes' classical reptation theory for reptation and healing of amorphous polymers, an alternative approach was developed to describe the strength development for semi-crystalline materials. A rudimentary description of the degree of melting was implemented to predict the bond strength as a function of the thermo-mechanical history at the interface during forming and subsequent resin injection for PA6 and PEEK, both semi-crystalline matrix materials.

The full article, “Analysis of the Thermoplastic Composite Overmolding Process: Interface Strength” can be found in Frontiers in Materials. Read more about TPRC’s overmolding research here.

Related Content

-

TU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

.jpg;maxWidth=300;quality=90)