Louis Dorworth Direct Services Manager

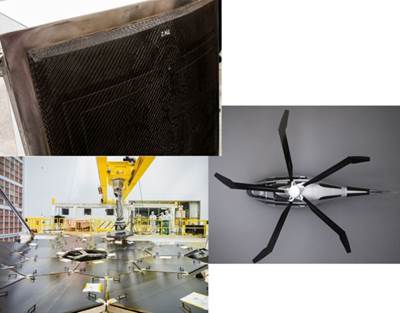

Alternate heat sources for hot-bonded composite repairs

Successfully using an alternate heat source for repairing composite structures requires an awareness of thermal dynamics and effective heat transfer management.

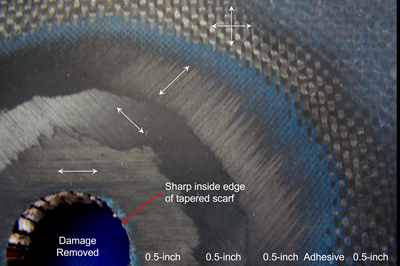

Read MoreA second look at cobonded tapered scarf repairs for composite structures

Composites repairs, such as cobonded tapered scarf repairs, seek to sufficiently restore structural loads so that components perform without failure

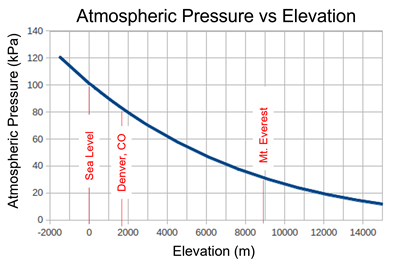

Read MoreAvoiding the pitfalls of vacuum infusion processing

Understand the fundamentals of vacuum infusion processing (VIP), including pressure, permeability and race tracking, to prevent issues and produce consistent results.

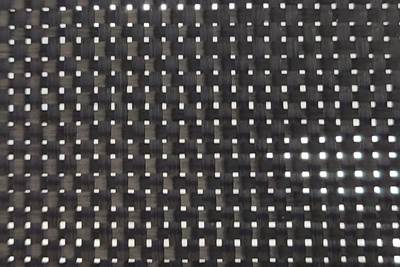

Read MorePorosity, voids and bridging in prepreg autoclave and vacuum bag-only laminates

Consideration of materials, methods and systems explores ways to reduce potential surface porosity, voids, resin-rich areas, bridging and other flaws in composite laminates.

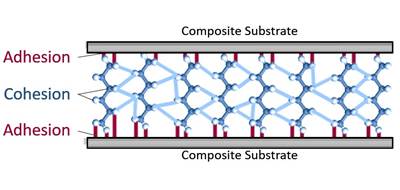

Read MoreTroubleshooting failures in adhesive-bonded composite joints

Cause of adhesive bonding inconsistencies or failure may be numerous. According to Louis Dorworth, the following points should be examined to determine the culprit.

Read MoreComposites at AeroDef 2018

Highlights from the Aerospace Defense Manufacturing Conference – AeroDef 2018 include new technologies for tooling, drilling/machining and inspection of advanced composites.

WatchComposite repair: Lessons learned, challenges and opportunities, Part II

In Part II, guest columnist Lou Dorworth says the wind and auto industries can learn much from the aerospace industry in this composites repair commentary.

Read MoreComposite repair: Lessons learned, challenges and opportunities, Part I

As aerospace companies look to increase the scope and quality of repairs, through standardized training and increased automation, their lessons learned (outlined here in Part 1 of a two-part examination) can smooth the repair path for other industries.

Read More