Composites at AeroDef 2018

Highlights from the Aerospace Defense Manufacturing Conference – AeroDef 2018 include new technologies for tooling, drilling/machining and inspection of advanced composites.

The Aerospace Defense Manufacturing Conference (AeroDef) is produced annually by the Society of Manufacturing Engineers (SME, Dearborn, MI, US). AeroDef 2018 (Mar 26-29, Long Beach, CA, US) featured over 225 exhibitors and more than 100 conference presentations. CW enlisted Lou Dorworth, SME member and Direct Services manager for Abaris Training Resources, Inc. (Reno, NV, US) to give a report on the composites-centered highlights from this year’s event.

SME’s AeroDef 2018 had plenty to offer for the composite enthusiast, including a pre-conference tour of Mission Critical Composites (Huntington Beach, CA) and two top-notch 3-hour composites-focused workshops. The first of these was a morning session geared to automated fiber placement (AFP) technologies and presented by Ramy Harik, assistant professor at the University of South Carolina (Columbia, SC, US). In the afternoon, Arnt Offringa, head of Aerostructures R&D at GKN Aerospace Fokker (Hoogerheide, Netherlands) gave an in-depth session on thermoplastic composite structures.

Pre-conference composites-focused activities included a tour of

Mission Critical Composites (Huntington Beach, CA, US).

NASA, Impossible Objects and Bell Helicopter recognized

Tuesday morning’s program started with the SME Award of Merit, presented by SME president Tom Kurfess, and awarded this year to Mr. Carroll Grant for his many years of volunteer leadership as an advisor for the composite manufacturing conference, as well as his contributions to the Composite Manufacturing Tech Group (CMTG), a technical community within SME.

Larry Pelham received the J.H. “Jud” Hall Award, for his work with large-scale upper-stage composite structures and cryotanks at NASA’s Marshall Space Flight Center (Huntsville, AL, US).

In addition, the CMTG presented Impossible Objects (Northbrook, IL) and Bell Helicopter (Ft. Worth, TX) with the Excellence in Composites Manufacturing awards which recognize one small and one large company that have demonstrated ‘excellence in the field of advanced composites manufacturing’. Impossible Objects was commended for their efforts with composite-based additive manufacturing (CBAM) technology while Bell Helicopter was lauded for its development of technologies, processes and automation for thick primary composite structures.

Conference highlights – drilling stacked laminates, tooling and bonding/layup NDT

The conference program included a “Composites and Advanced Materials” track with 25 different presentations ranging in topics from low-cost material forms and tooling to automated layup and new innovations in composite additive manufacturing. Several presentations discussed drilling and machining of composites, including a comprehensive comparison of cutting tools needed for composites vs. metals by Brian Ross from MAPAL, Inc. (Port Huron, MI) and a primer on minimizing erosion at the carbon fiber (CF) to titanium (Ti) interface in CF/Ti stacks using micro-peck drilling technologies presented by Tim Holmer from OSG USA (Irving, TX).

BTG Labs Surface Analyst display and demo station on the AeroDef 2018 exhibit floor.

There were over 225 exhibitors on the show floor, many of which were involved with composite manufacturing or services. Ascent Aerospace (Santa Ana, CA) had their latest tooling concept, the HyVarC hybrid invar and carbon fiber demo tool on display in their booth. BTG Labs (Cincinnati, OH, US) shared a booth with Abaris Training Resources, Inc, (Reno, NV) and provide attendees with continuous demonstrations of their Surface Analyst equipment, used for surface quality verification for both metal and composite bond-surfaces. Aligned Vision (Chelmsford, MA, US) displayed the latest FOD detection and reporting capabilities integrated into their LASERVISION laser projection systems, touting it as an in-process safeguard against leaving inclusions in a layup. DUNA-USA (Baytown, TX, US) showcased their new Black Corintho 800 line of tooling board which has high temperature (400˚F/204˚) capabilities, good heat transfer properties and relatively low coefficient of thermal expansion (CTE).

Machined Black Corintho 800 High-temperature, low-CTE tooling board sample.

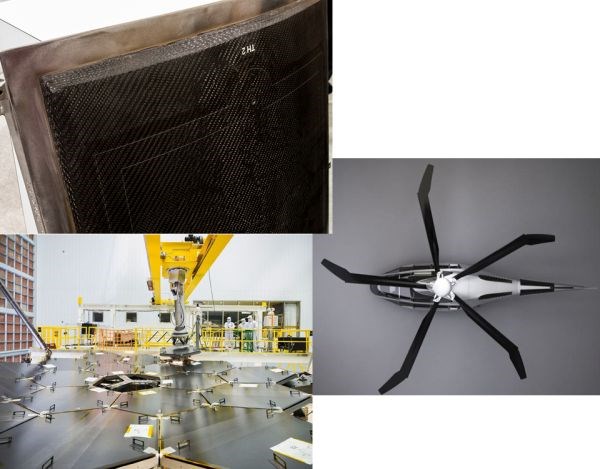

AeroDef ended on a high note with a Thursday afternoon tour of the Northrop Grumman Aerospace Systems Space Park (Redondo Beach, CA, US), where the attendees got a peek at components for assembly of the James Webb Space Telescope manufactured and assembled at this facility. The telescope, originally scheduled to launch in October of this year has been rescheduled for May 2020.

AeroDef 2019 is planned to be held again next year in Long Beach, April 29th-May 2nd. With growth every year since its inceptions, conference planners anticipate greater exhibitor participation and a larger attendance at next year’s event.

Related Content

A new era for ceramic matrix composites

CMC is expanding, with new fiber production in Europe, faster processes and higher temperature materials enabling applications for industry, hypersonics and New Space.

Read MoreTU Munich develops cuboidal conformable tanks using carbon fiber composites for increased hydrogen storage

Flat tank enabling standard platform for BEV and FCEV uses thermoplastic and thermoset composites, overwrapped skeleton design in pursuit of 25% more H2 storage.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read More