Life Cycle Assessment: Are composites "green"?

Methods for calculating the impact composites have on the environment enable data-driven comparisons to traditional materials on a level playing field.

How green are composites? That question is asked more often than ever by consumers concerned with the environmental impacts of manufacturing. “The public has the perception that composites, many of which come from oil, are not green and are polluting,” observes Bill Kreysler, president of Kreysler & Assoc. (American Canyon, Calif.). “But this is a myth. They can be much greener than you think in the right applications because of their strength and light weight.”

Debunking that myth, however, is no simple task. Myriad factors determine a product’s environmental impact but manufacturers increasingly use Life Cycle Assessment (LCA) to help quantify their products’ environmental footprint.

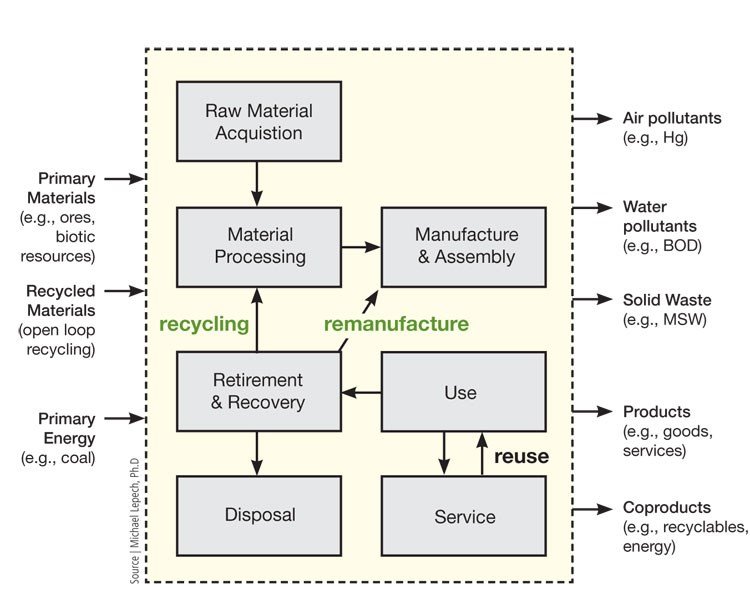

Also known as “cradle-to-grave” analysis, LCA seeks to determine and evaluate every environmental impact represented by the manufacture, use and disposal of a product. Impact data give manufacturers a convincing way to market a product as environmentally sensitive and demonstrate to both customers and shareholders their commitments to sustainability, says LCA expert Dr. Michael Lepech, an assistant professor in the Department of Civil and Environmental Engineering at Stanford University.

LCA gives composites a data-driven leg to stand on, says Cheryl Richards, chair of the American Composites Manufacturers Assn.’s (ACMA, Arlington, Va.) Green Composites Committee and the global marketing manager for wind energy at PPG Industries Inc. (Pittsburgh, Pa.). “We can tout the advantages with real data — it finally gives composites equal footing with traditional materials when you consider all parts of the product’s life cycle.”

A means to define green

LCA was popularized decades ago, when environmentalists raised concerns about diminishing material and energy resources coupled with a growing world population. First used in the food and beverage industry, LCA has spread to other sectors, driven in part by the European Commission’s Environment Directorate, which requires manufacturers to monitor energy and raw-material consumption and solid waste generation.

Today, LCA methodology is spelled out in the International Organization for Standardization (ISO) 14040 environmental management series standard, which consists of four major steps: 1) goal and scope definition (§4.2 ISO 14044); 2) inventory analysis (§4.3 ISO 14044); 3) impact assessment (§4.4 ISO 14044); and 4) interpretation (§4.5 ISO 14044). Each step, as noted in the following paragraphs, presents considerable challenges, say LCA practitioners.

Goal and scope definition. According to Lepech, each LCA starts by defining a goal and the “functional unit” of the study — that is, the service provided by the material, component or system and its performance characteristics. For example, to compare the impacts of two desks — one made with steel, aluminum and laminate and the other with wood — a researcher must define a quantifiable unit in order to compare the parts, such as the desk’s working surface area. “The functional unit is needed in order to establish a quantitative equivalent between two comparable products or processes, so that the impacts can be assessed,” Lepech explains. For an LCA that compares building materials, the functional unit might be one board-foot or other dimensional unit large enough to meet the project requirements for stiffness. Although the LCA’s scope of investigation ideally is cradle to grave, there are situations in which the scope may be limited, for practicality’s sake, without compromising study conclusions.

Inventory analysis. This step requires legwork. Investigators must determine all of the possible inputs to and outputs from the functional unit that have an impact on the environment. Inputs include the upstream impacts of raw materials (e.g., sand for glass manufacture); the energy used to mine or extract the raw materials; the fuel costs to transport the raw materials to the manufacturing site; the energy used to transform the raw materials into the product (e.g., from natural gas or coal); the energy use associated with any recycled materials in the product; and so forth. Outputs include the downstream impacts of air pollutants (e.g., greenhouse gases); water pollutants; solid waste (e.g., disposal and/or recycling of the product itself); any coproducts that can be beneficially reused; and more. For a list of published data sources for conducting life cycle inventories, see the sidebar at the end of this article or click on "Life Cycle Assessment resources" under "Editor's Pick's," at right.

Impact assessment. Software is available to help LCA investigators navigate the somewhat arduous process of the inventory analysis and assessment steps, including SimaPro and ECO-it from PRé Consultants (Amersfoort, The Netherlands) and GaBi from PE International (Stuttgart, Germany), among others. There also are many options for limiting the scope of a study with a streamlined or partial LCA that reportedly still provides sufficient information for assessment. That said, the process remains as much an art as science, in part because the required data inputs, while available for some processes, are absent for others. Further, assumptions about data inputs and the relative weights of environmental impacts differ among the software packages.

Interpretation. This step is a challenge because assumptions about data input and the relative weight of impacts also differ among those who use the software. “Interpretation of LCA results can vary,” confirms Bob Moffit, product manager at Ashland, LLC (Columbus, Ohio), who heads the company’s green resin efforts. “Some results are weighted more than others, depending on their importance to the manufacturer or end-user,” he explains. “Some people might put more emphasis on carbon dioxide [CO2] emissions, for example, than solid wastes.” Given the potential for interpretive variation, an LCA study typically undergoes a third-party review to ensure that the results are credible.

The LCA provides a means for modifying designs to optimize environmental friendliness. In Lepech’s desk example, the wood desk consumes more materials in total and produces more solid waste, but more than 60 percent of the steel and aluminum desk’s total life cycle energy use is taken up by the highly energy-intensive aluminum extrusion process needed to produce the castors on the desk’s legs. That energy use could be decreased somewhat by increasing the amount of recycled aluminum in the desk, he points out, or by eliminating the castors. Likewise, the impacts of composite materials and manufacturing often can be mitigated with judicious material selection or small changes in design, he emphasizes.

As consumers demand more environmental information about new products, LCAs are expected to grow in importance. Environmental Product Declarations (EPDs), for example, inform purchasers about the environmental impacts, based on LCA data prepared in accordance with ISO 14025 guidance. EPDs are the equivalent of the nutritional information now standard on food packaging. Richards says that many U.S. companies, particularly those in the building materials market, are scrambling to market products with green labels, including not only EPDs but also the Leadership in Energy and Environmental Design (LEED) Green Building Rating System, developed by the U.S. Green Building Council, and the Energy Star program, a long-standing joint effort of the U.S. Environmental Protection Agency and the U.S. Department of Energy.

“Right now, building material specifications are listing LCA as an option,” reports Gary Jakubcin, Owens Corning Composite Solutions Business (Toledo, Ohio) LCA process head and the cochairman of ACMA’s Green Composites Committee Life Cycle Inventory subcommittee. But he warns that “in the near future, it might become a requirement for selling your product.” Beginning Jan. 1, 2011, for example, EPDs will be required for products sold in France. “Learning about LCAs and performing them to document your product’s impacts is becoming a business necessity,” he maintains.

LCAs enable composites marketing

Several composite materials suppliers have conducted or participated in studies of their own products to facilitate green marketing campaigns. Others, typically university researchers and students, have conducted LCAs focused on the use phase to compare composite products with those made from other materials.

An example of the former are studies conducted since 2006 by Owens Corning on its internal processes. The company’s core business strategy includes reducing the negative impacts of its manufacturing operations, increasing the positive impacts of its products and assisting customers in reducing their carbon footprints, says Frank O’Brien-Bernini, the company’s chief sustainability officer. A case in point involves Owens Corning’s Advantex E-CR corrosion-resistant E-glass product. According to O’Brien-Bernini, an LCA demonstrated that the fiber’s total life cycle environmental impact could be mitigated if the company replaced its glass melting furnaces with new units that use more fossil-fuel-efficient gas/oxygen firing technology. The new furnaces were installed and now reduce CO2 emissions by 40 percent, nitrogen oxides by 75 percent, sulfur oxide by 40 percent and particulates by 90 percent. At Owens Corning, greenhouse gas emissions at plants equipped with the new technology are, on average, 23 percent lower. Says O’Brien-Bernini, “Thanks to these LCAs, we can now transcend narrow, single-attribute material comparisons, like recycled content, to represent the true sustainability benefits of composite applications.”

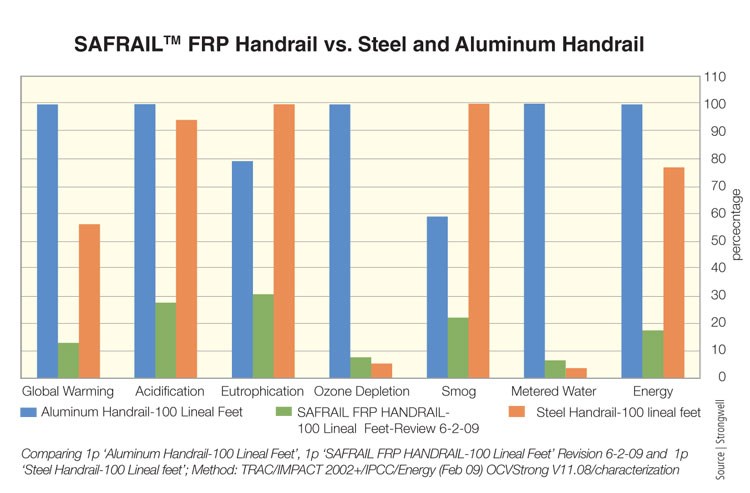

Owens Corning recently worked with its customer Strongwell (Bristol, Va.) to produce a “cradle-to-gate” LCA. This partial study stopped at Strongwell’s front gate and did not consider transportation to downstream customers or specific end applications that might have required additional procedures (e.g., fastening). Nor did it consider use and end-of-life impacts. It compared pultruded composites with aluminum and steel for five structural parts: grating, handrail, U-shaped channel, channel-and-tubing combination and floor plate. The functional units were 100 ft²/9.3m² for the grating and floor plate and 100 linear ft (30.5 linear m) for the handrail, channel and channel-and-tubing combination. Developed by an industry consultant who used SimaPro7 LCA software, the study examined the embodied energy of the raw materials and processing needed to create each product. Among the materials under consideration were Advantex glass fiber, a general-purpose polyester resin, A517I low-carbon steel, three grades of aluminum (ranging from virgin to 80 percent recycled content) and kiln-dried pine.

According to the study results, the embodied energy represented by the composite parts is lower when compared to aluminum parts made with virgin aluminum and steel primarily because the composite delivers better strength-to-weight. The report assumes that as more recycled content is added to the aluminum and steel, their energy use and environmental footprint would be closer to the composite components. As might be expected, the wood materials had a significant advantage over composites, with a 50 percent lower embodied-energy footprint. A take-home message from the report is that the impacts represented by a composite part increase as its percentage of resin increases. Therefore, increasing fiber content and/or reducing styrene in the resin can “green” the product. Strongwell’s environmental manager, John Barker, notes, “We have chosen LCA for determining our environmental impacts because of its quantitative nature and scope and because the resulting reports are peer-reviewed for objectivity.”

Ashland’s Envirez 1807 bio-resin, made with soy oil and corn ethanol, was the subject of an LCA performed by consultant Jim Pollack (Omnitech International, Midland, Mich.) for the United Soybean Board (USB, St. Louis, Mo.). Pollack explains that LCAs of bio-based materials involve evaluating additional factors, such as the ability of the source plants to fix nitrogen, how much fertilizer and fuel is required for cultivation and the sequestration of carbon within plants, among others. “Because soybeans are nitrogen-fixing plants, nitrous oxide emissions from soybean fields are lower than for other crops. This helped keep the global warming potential [GWP] of the Envirez resin lower than the equivalent petrochemical resin.”

The USB LCA, like the Strongwell study, included only upstream and resin production impacts and stopped at the facility gate. Downstream delivery, application and use phases were considered equivalent and, therefore, out of scope. The results showed that the GWP for the Envirez resin, when compared to a petrochemical resin (also manufactured by Ashland), was 4.1 kg/9 lb of CO2 equivalents per kilogram or pound of resin produced vs. 5.2 kg/11.5 lb of CO2 equivalents for the petrochemical-based resin (“CO2 equivalents” is a common LCA term that expresses greenhouse gas emissions, and thus GWP, referenced to CO2). In terms of energy impact, Pollack reports that Envirez consumes 2,567 fewer BTUs/lb of resin produced during manufacture than the petrochemical resin. Moffit says that fact enables Ashland to state with confidence that resins made with renewables offer tangible environmental benefits for their customers.

3A Composites (Sins, Switzerland) has gone a step further and developed an LCA tool called the Hybrid Core Calculator. The tool calculates a simplified LCA, based on inventory data for typical sandwich panel components, core and skin. After inputting data on a project’s sandwich design requirements (panel size and thickness) and the performance loads, the calculator quickly produces environmental impacts for each phase of a core product’s life cycle. It then displays energy consumption, greenhouse gas potential (in CO2 equivalents), water consumption and other ecological indicators, says the company. In one example, a double-decker city bus with a composite sandwich (instead of steel) upper floor has 30 percent lower weight, says 3A, and its ecological impact is reduced by 30 percent over the bus’ life cycle because of greater fuel efficiency.

LCAs and automotive composites

Krishnan Jayaraman of the Department of Mechanical Engineering at the University of Auckland (Auckland, New Zealand) says that end-of-life directives in Europe and Japan are forcing automotive OEMs to apply LCA techniques to their manufacturing processes to better understand the environmental effects at all stages of production. In a recent paper, he and coauthor Xun Xu described a study that compared automotive doors, hoods and trunk lids made with steel, aluminum, fiberglass/polyethylene terephthalate (PET) and carbon fiber/epoxy (30 percent fiber volume). The LCA results showed that the carbon fiber/epoxy panels had the lowest environmental impact scores, primarily, says Jayaraman, because of their lower weight and higher strength.

He notes, however, that in the event of a crash, the panel replacement would overshadow the environmental benefits because aluminum and steel panels can be readily repaired. In another automotive LCA, adds Jayaraman, a bumper beam made of unidirectional fiberglass in a polypropylene matrix had a lower environmental impact than a steel bumper beam. As was true with the previously discussed bus floor, the lighter composite beam consumed less energy by enabling greater fuel economy over the vehicle’s useful life, a key point emphasized by many LCA proponents.

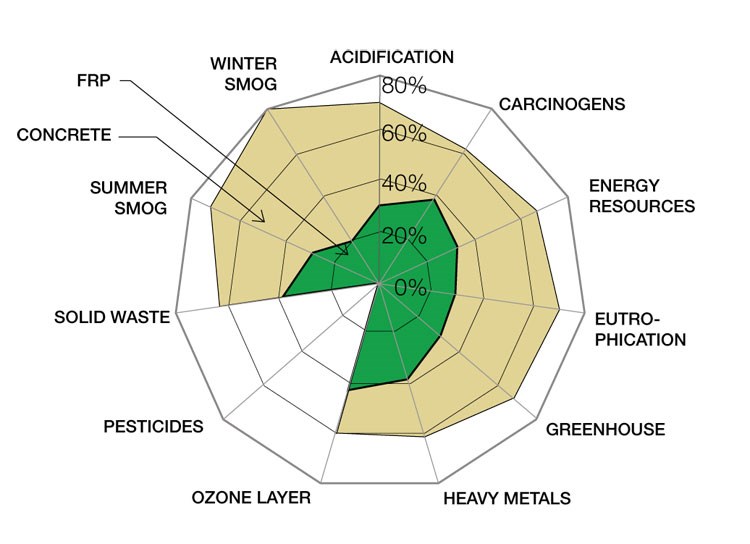

A much-discussed LCA, performed by Lepech and a group of his students at Stanford University, examined a fish tank for the Monterey Bay Aquarium in Monterey, Calif. The aquarium wanted a large, freestanding, seismic-resistant tank, approximately 20 ft by 40 ft by 10 ft (6.1m by 12.2m by 3m), capable of sustaining a saltwater aquatic ecosystem for 20 years. A glass/polyester tank designed by Kreysler’s firm was one option; the other was a concrete design with a smooth “shotcrete” (sprayed concrete) lining. Lepech developed a detailed process flow diagram for both material systems. For the concrete tank, the raw materials — including limestone, gypsum, cement rock and aggregate — and the extraction activities associated with them were identified, as were the raw materials for the formwork (timber and glues to make the plywood) and the reinforcing bar (pig iron and other metals to make the steel). Environmental impact estimates were made of the equipment needed to produce the concrete tank (cement mixer, pumps, etc.), maintain it over its life span (cleaning equipment) and, finally, demolish it and transport it to a landfill.

The same process components were developed for the glass fiber-reinforced polymer tank, including the raw materials to produce the fiberglass filaments (sand, feldspar, sodium sulfate, borax, etc.); the energy consumed to melt the raw materials and extrude and wind the glass fiber filaments; and the raw ingredients and processing steps to produce the polyester resin. Ashland was actively involved in the tank study and provided resin process data to Lepech, notes Moffit.

Lepech and Kreysler confirm that the data showed the fiberglass/polyester tank solution had significantly less impact than the concrete tank on many environmental fronts (see diagram on this page) because the mining and extraction of the cement and other concrete materials is not only energy-intensive, but it also involves more shipping and generates more air pollution.

A recent LCA study funded by InnoVida Holdings LLC (Miami Beach, Fla.) and conducted by Florida International University College of Engineering and Computing (Miami, Fla.) compared the environmental performance of InnoVida’s manufactured composite house panels with conventional house construction methods. Two graduate students, supervised by Drs. Yong Tao and Yimin Zhu, developed a 1,200-ft²/111.5m² five-room, single-story “patio reference house.” The conventional version featured masonry block reinforced by rebar and cement grout, with gypsum wallboard over batt insulation on the interior walls. The roof trusses were structural lumber beams covered with plywood panels and R-30 batt insulation.

In contrast, the InnoVida house was constructed entirely of the company’s proprietary 4-inch/101.6-mm thick sandwich panels for the roof and exterior walls and similar 2.5-inch/63.5-mm thick panels for interior walls. The panels feature an insulating polyurethane core with integral stiffeners between glass fiber/epoxy skins. The panels were bonded onsite with Innovida’s proprietary adhesive.

Tao and Zhu developed a basic life cycle inventory of only the raw material inputs and manufacturing processes necessary to create one board-foot of panel vs. one board-foot of traditional masonry construction. Then they calculated the GWP (in CO2 equivalents) of both construction types using the ATHENA Impact Estimator, published by the Athena Institute (Merrickville, Ontario, Canada). Although the study’s scope was limited, it showed that if the effects of the bonding adhesive are ignored, the total impact of the composite panel house is significantly lower — by about 50 percent — than the reference house. When the adhesive is included, the impact of the composite panel house is 25 percent less than the traditionally constructed house. Zachary Waksal, InnoVida’s VP of business development, says, “We are trying to change the construction paradigm by using innovative composite technology that allows for greater speed of construction, affordability and sustainability.”

Kreysler tells a cautionary tale about an LCA that compared real stonework with a proprietary fiber-reinforced (FRP) cladding material engineered to look like stone. Says Kreysler, “It seemed on the surface like the FRP solution had to be better, when you considered the extraction of the stone from the quarry, the shipping logistics, not to mention part weight.” But the LCA showed that the medium-density fiberboard (MDF) used to make the molds for the FRP parts made the composite solution much less environmentally sustainable because of the energy-intensive process used to produce the MDF. “It proved that you have to look at the entire process ... from beginning to end,” Kreysler adds.

What’s next?

LCA is immensely promising and very new to composites. “We’re at the start of the journey right now,” says Richards. There is, necessarily, much work to be done. Indeed, the ACMA Green Composites Committee’s Life Cycle Inventory subcommittee headed by Jakubcin is focused on developing more inventory data specific to composites, something that is in short supply at present, using a standard pultrusion process as the first model. ACMA also is in the process of educating its members about LCAs and their benefits. Green training sessions will be held at its COMPOSITES 2011 trade event, which commences Feb. 4, 2011, in Fort Lauderdale, Fla. (see CT’s ACMA COMPOSITES 2011 show preview, under "Editor's Picks," at right).

The most important factor, however, is that LCAs need to come into wide use. “Everyone in the composites industry needs to get in the game,” says Owens Corning’s O’Brien-Bernini. “This is a positive thing for composites — it’s not emotional anymore. We can now compete with traditional materials on fact-based green attributes.”

“Our industry needs to show the life cycle benefits of composites,” concludes Ashland’s Moffit. “We’ve made some progress, but as an industry, we need to do much more.”

Related Content

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreComposites end markets: Automotive (2024)

Recent trends in automotive composites include new materials and developments for battery electric vehicles, hydrogen fuel cell technologies, and recycled and bio-based materials.

Read MoreRead Next

Modeling and characterization of crushable composite structures

How the predictive tool “CZone” is applied to simulate the axial crushing response of composites, providing valuable insights into their use for motorsport applications.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read More